Redfluid obtains BV Mode II recognition from Bureau Veritas

It’s official! Redfluid has been recognized by Bureau Veritas under the BV Mode II scheme — or as we call it in the industry, Company

Did you know that a valve or fitting can be certified in many different ways?

We have material certificates that tell us what type of material it is (for example, 316 Stainless Steel or A105 Carbon Steel), or we can certify that the product has no leakage and can withstand X pressure.

Let me tell you a little more.

In the industrial world, a certification represents a recognized document that allows the company to demonstrate to customers and partners that it complies with a specific standard in its production process and supply and technical specifications of materials.

Even my neighbor knows this, but the relationship between company and customer is based almost 100% on mutual trust.

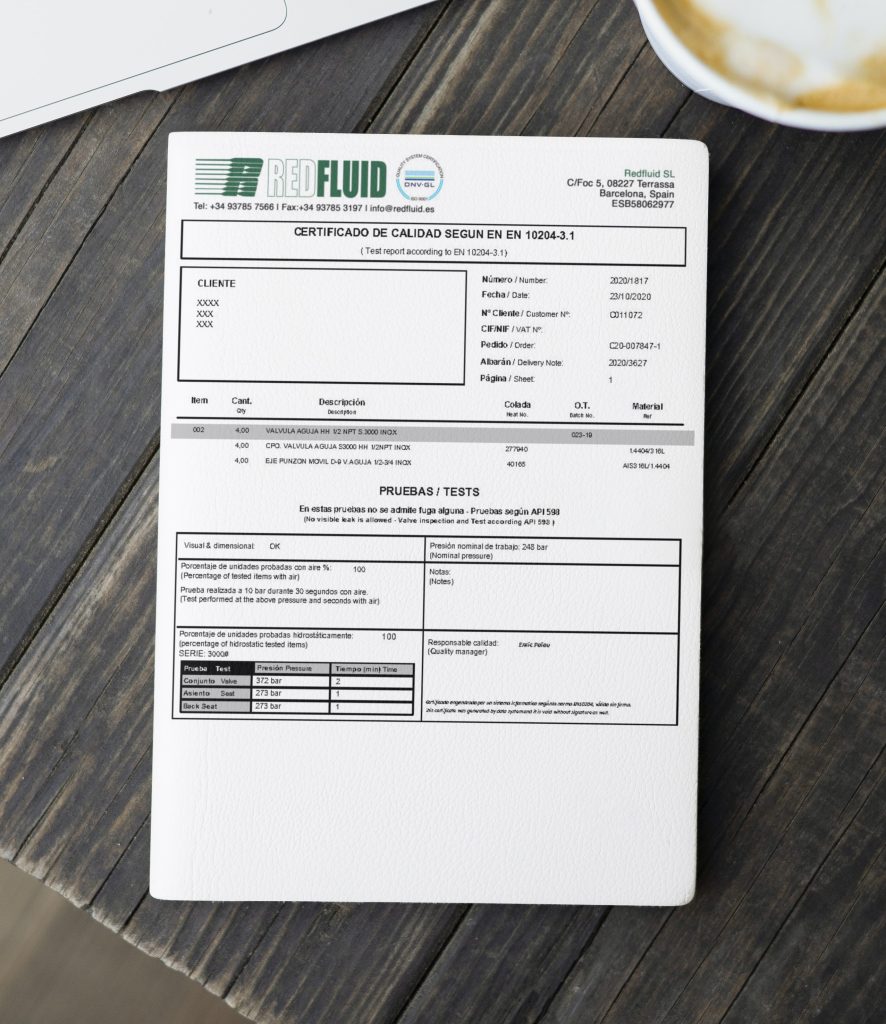

Euro Standard certificates such as the EN 10204 Certificate (inspection for the supply of metallic materials) allow increasing the confidence of these customers and partners since this shows that the companies are reliable and, therefore, they are a pass to access different markets and potential consumers.

But… How can I find out more about this?

Below, I will show you all the standards that can issue a quality certificate.

Come on, let’s get down to business.

The European standard DIN or UNE EN 10204:2006 specifies the different inspection and control documents that, according to the order requirements, are delivered to the buyer or customer.

Please pay attention to this to carry out these inspection documents and the corresponding types of certificates indicated in the standard. It is necessary to have the product specifications and the tests of each unit produced in writing.

Therefore, the importance of the EN 10204 standard, which lies in the certification that the equipment built with such metallic materials complies with the details defined in the datasheet or certified drawings at the time of manufacture and delivery.

Yesssssss so you see, if you want to supply quality products you must ask for this certificate!

Here comes the big question….

We tell you that to make these inspection documents and the corresponding types of certificates suggested by the standard. It is necessary to have each unit’s product specifications and tests produced in writing.

Here is some good advice:

“We recommend you to request the EN10204 certification before making the offer or before finalizing your order. Otherwise, this may result in extra costs, testing, inspections of the units produced, and time to perform or ensure the quality of your products.”

Okay, here is a list of the main aspects you have to consider in the inspections:

Non-specific inspections are carried out by the manufacturer with his means, indicating the conformity of the material with all the conditions required in the order without providing any test. The inspected product is not necessarily the one supplied.

Specific inspections: inspection carried out before delivery according to product specifications to verify that they meet all the product requirements.

Of all the control and inspection methods under EN 10204, we will focus on the most commonly used certificates with their requirements. Today I will explain certificate type 2.2 (non-specific inspections) and type 3.1 and 3.2 (specific assessments).

In this document, the manufacturer declares that the products supplied follow all the order requirements and provides the results of tests based on its inspection processes to comply with the requested standards.

Another type of certificate 2.2 is the one made through a thorough and random analysis performed on the products of a given batch or order as a test. These dimensions should be considered generic, and under no circumstances should they be interpreted as exact measurements of the product or batch. It should be noted that the manufacturer is not obliged to perform this analysis every time a product is manufactured.

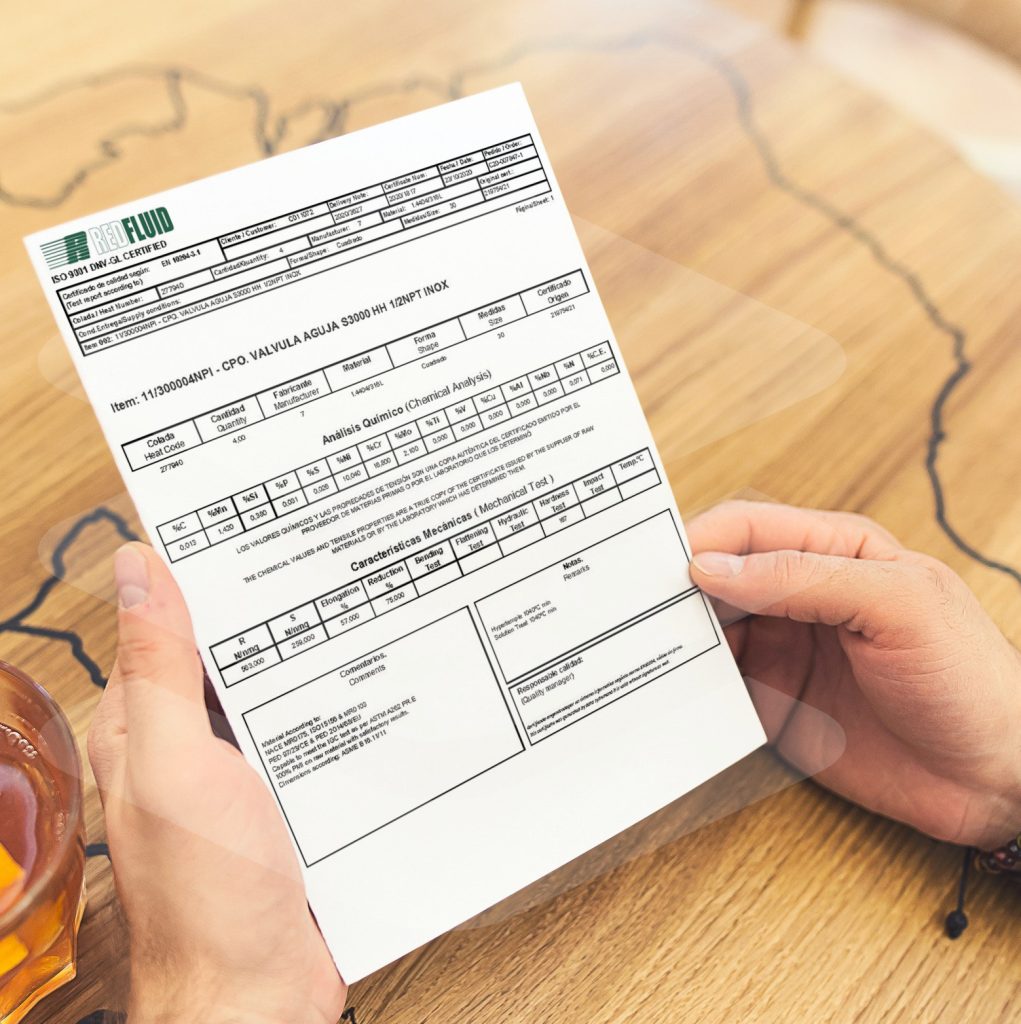

At Redfluid, the type 2.1 or 2.2 certificate is instead a statement indicating that a part has been manufactured with a specific grade of material, i.e., that the stainless steel is type 316/L and, therefore, is not Carbon Steel, for example, and generic tests have been carried out on random batches to obtain it.

This document is also issued or must be supplied by the manufacturer, and it states that the products delivered meet the requirements requested in the order or order placed, highlighting the type of test and how to perform it. This must be previously defined in the order request or order.

Generally, the person who grants this report is usually a staff outside the production department of the manufacturer, so in most cases is performed in quality control laboratories and has a high economic cost. Still, the required control documents are provided to verify the certificate’s authenticity.

Whatever requirement demanded a specific item, the 3.1 certificate is the guarantee that it was correctly executed.

At Redfluid, we deliver this type of certificate, and they include all the chemical and mechanical specifications of the raw material with which the supplied part has been manufactured.

The type 3.2 certificate must be validated by the manufacturer and the customer, either under a firm or auditing company acting on behalf of the customer. The results of these tests based on specific inspections are provided on the sole condition that it can demonstrate traceability and that the product complies with the requested requirements. Usually, this certificate requires third-party companies to audit the quality of the products, such as TUV or Lloyds.

Yes, we know that finding all the standards you need in one place can save you about 700 hours of research, but here comes another exciting question ….

– What if the material of manufacture of a product is correct, well designed, and specified, but how do I certify that my equipment is not leaking and will withstand the required pressure?

Standards were made to be applied, so let’s pull them one more time! In this case, we will explain the testing and pressure and leakage standards which we will detail below:

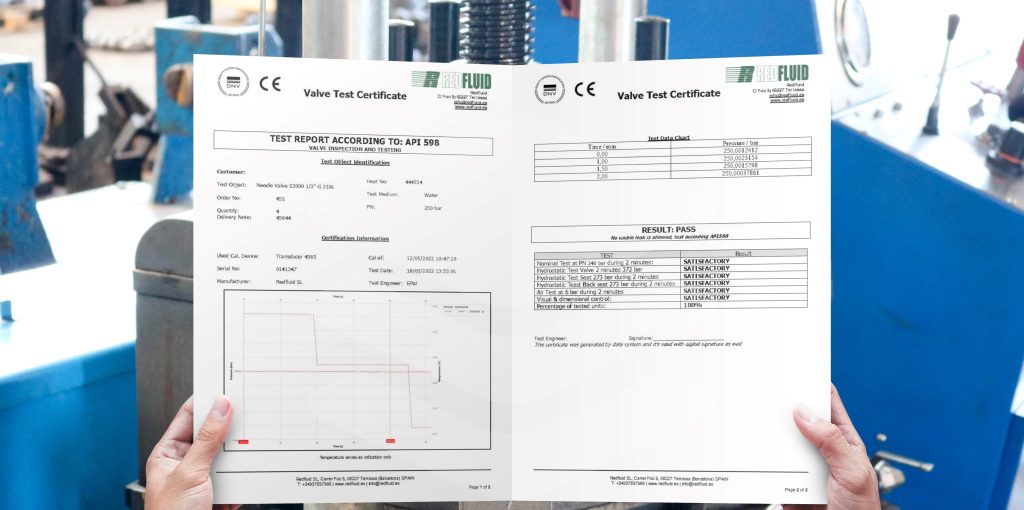

The mission of this standard is to perform a complete diagnosis of the valve and all pressure testing requirements. It is used in the case of needles, ball, or check valves.

In this case, the valves are tested for leak tightness as follows.

Hydrostatic tests:

Pneumatic Tests:

In any of these tests, no leakage is allowed.

It is considered an industry standard for ball valve seat leakage. To diagnose Class VI leaks, tests are performed with air or nitrogen at the working differential pressure or around 3.5 bar, whichever is lower.

The admissible leakage is evaluated in bubbles/min or ml/min according to the standard table. It should be noted that class VI leaks are used when the seal is metallic in sizes smaller than 2″ inches and do not admit any bubbles.

This European Standard specifies test requirements, test procedures, and acceptance criteria for production testing of industrial valves made of metallic materials.

The specified tests can also be used as type tests or acceptance tests. It is similar to API598:

If you want to know more about the type of valves that use these standards to be certified, we invite you to see the post Is my ball valve suitable for hydrogen? Don’t forget to subscribe to our blog to stay informed about the latest news on instrumentation, control, and processes.

And, if you’re a quality nut, we also have a new test certificate format where you can see a graph of the entire pressure test cycle we perform. It’s not free like the standard one, but it doesn’t cost more than a mojito if the occasion calls for it.

Share this post

It’s official! Redfluid has been recognized by Bureau Veritas under the BV Mode II scheme — or as we call it in the industry, Company

A looot of people believe the stainless steel they have in their factories is 316, but they soon realize their materials are not that resistant