Redfluid manufactures custom valves and fittings to meet all your requirements. With immediate delivery.

Unable to find the valve you need? We know that could mean losing a client to your competitors. Or having to modify your plant or machine design. Or, even, shutting down your equipment until you receive the missing part from the other side of the world.

Over 35 years, we have made thousands of custom parts and helped our clients to meet their deadlines and their client’s requirements.

We modify all kinds of high-pressure valves, especially ball, needle and check valves. Dimensions, higher-pressure adjustments, connection changes, non-standard material manufacturing, special finishes and much more.

We can manufacture from a blueprint, from a sample by reverse engineering or from scratch, based on your requirements. A whole team of design and manufacturing experts will be working by your side.

We offer additional services such as surface treatments, heat treatments, part engraving, etc. We also draw up certificates or technical reports according to client specifications

We supply a great team of professionals and the best national technology when it comes to part manufacturing. With high levels of quality and according to the main worldwide certifications. Our goal is to provide you with what you need, faster than by importing parts, and with more guarantees.

Let us know what you need and get your personal proposal with an explanatory outline. After your approval, we prepare the final drawing, manufacture the part and ship it in a few days—depending on your deadline requirements.

Connections

NPT, BSP, BSPT, SW, BW, SCH, ISO, SAE, DIN, FERRULE and more

Materials

Steel and exotic materials such as duplex, super duplex, Alloy20, Hastelloy, PVA, PTFE and more.

Temperature

For applications from cryogenic up to 800 °C temperatures.

Certificates

We manufacture in compliance with ISO, ATEX, CE/PED, EAC, Fire Safe, SIL-2 Standards.

Valve Bore

We make both reduced-bore and full-bore valves.

Clean and grease-free

We manufacture valves meeting the food industry standards degreased for oxigen service.

Deadlines

Get your personalized valve in a few days.

High pressure

We manufacture for pressure from vacuum up to 4000 bar.

Specialists in high-pressure valves and fittings.

We can meet all your requirements: exotic-material valves, valves for corrosive environments or valves operating under extreme temperature or pressure conditions. With high manufacturing tolerances, coatings, heat treatments or special final finishes.

If it’s not in our catalog, we make it for you. Always in compliance with all certificates and quality criteria. Contact us: we’ll find the best solution for your needs:

Our Method

1. Options consideration

after receiving and analyzing your request, we try to find a solution among our standard products in order to provide a quick and economical solution.

2. Manufacturing proposal

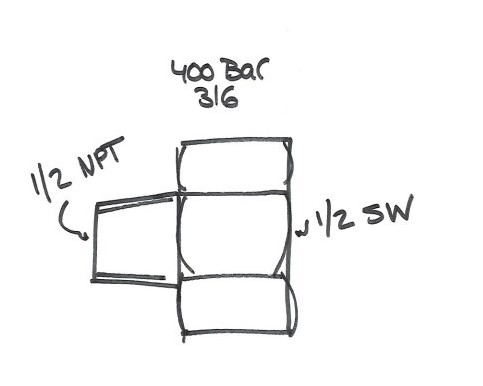

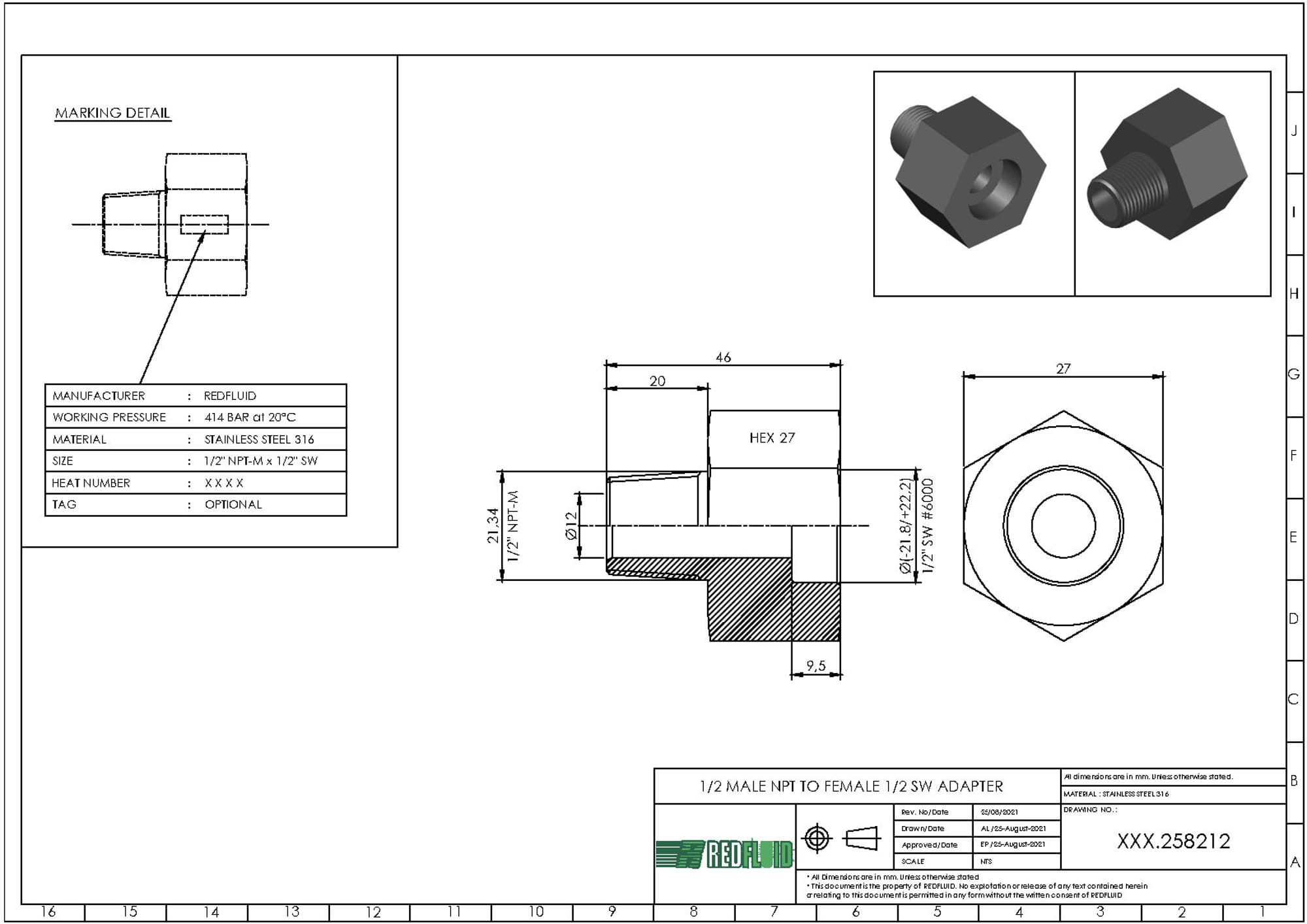

If there is no standard solution, we design a part that fits your requirements and send you the blueprint for your approval.

3. Prototyping and manufacturing

After your blueprint approval, we make a 3D printing prototype (optional) and manufacture the part.

4. Tests and trials

Once we have the part, we perform the necessary tests to verify that it meets all quality requirements.

5. Additional services

We finally take care of the finishing, the marking and any extra service you may request (see below our additional services). When everything is ready, we properly pack your piece and ship it wherever you need.

Redfluid Laser Marking

Heat And Surface Treatments

Galvanizing, zinc plating, anodizing. Tempering, annealing, stelliting, silver plating.

Part Marking And Engraving

Mark your parts with laser or a punching machine. Names, Tags, serial numbers o any other reference.

CAD And 3D Prototyping

During the designing stage, we make blueprints and prototypes to ensure compliance with all requirements.

Special Cleaning

Our special cleaning and degreasing service meets the standards of medical and food applications.

Pressure And Leak Testing

We test pressure and leakage to meet all requirements or solve any problem of the part.

Technical Reports

We prepare certificates or technical reports according to our client’s specifications. PMI test certificates.

Welding Or Assembly

We perform post-manufacturing processes such as welding or assemblies for different types of materials.

Blasting

Blasting processes to sand and clean surfaces. Preparation for other surface treatments.

Redfluid's manufacturing guarantee

All our valves are individually tested:

- Dimensional and thread control with approved gauges.

- Pneumatic tests with nitrogen or helium 100% API 598 and EN 12266.

- Hydrostatic tests 100% API 598 and EN 12266.

- Full traceability and material certification according to EN 10204.

Being totally customized parts, made to order valves cannot be returned. To avoid disagreements, we provide technical advice from the very first moment. Prior to manufacturing, the client needs to approve our blueprint. This is our way to make sure we meet all your requirements.

Contact and request your customized piece

We manufacture and adapt all types of valves and high-pressure connections, with European quality, certifications and short delivery times. Contact us and tell us what you need.