Flushing Ring: the key to cleaning and calibration without disassembly

Imagine you’re running an industrial plant and you’ve got a diaphragm seal protecting a pressure transmitter. Over time, the process fluid starts leaving deposits and

Do you know the difference between a 3-way valve and a 3-piece valve?

There’s a lot of confusion on this topic, and many times you end up ordering something you don’t want because you mixed up these two types of valves.

If you don’t want to get confused when ordering these valves, I’m going to explain everything so you never make this mistake again!

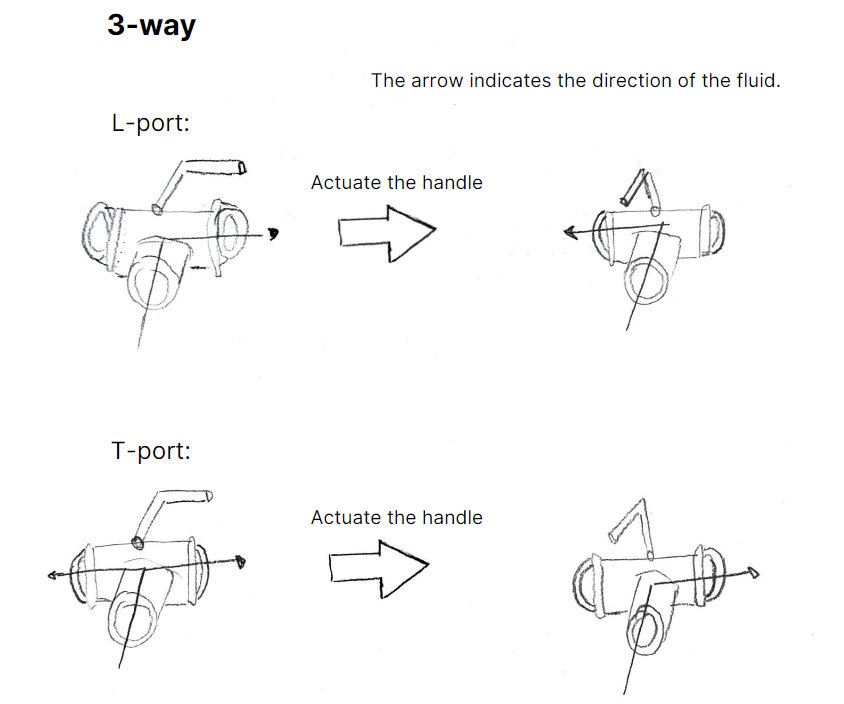

3-way ball valves are devices primarily used when you need to distribute flow. They have 3 ports or connections, usually with one inlet—typically the central port—and two side outlets. However, as you’ll see later, we also offer an alternative.

Within these devices, there are different configurations depending on how they distribute the flow.

If you’d like to see a more in-depth article where we only talk about 3-way valves, click here.

Additionally, here is the datasheet for our 3-way ball valves.

Now that you’ve got a clear understanding of what a 3-way valve is, let’s take a look at what a 3-piece dismountable valve is.

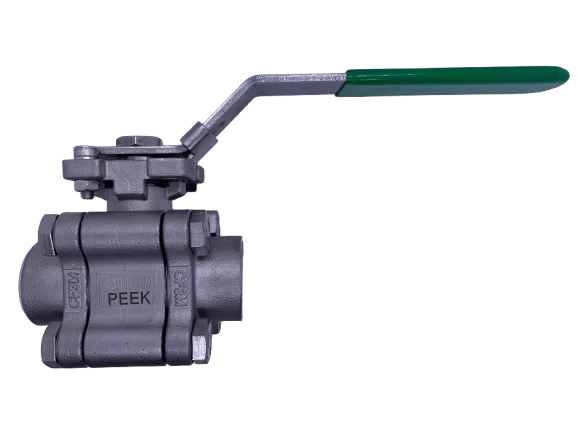

3-piece valves, as the name suggests, consist of three parts: two end caps and a central body. This design offers significant advantages in terms of maintenance, cleaning, and the durability of the equipment.

Below are the most significant advantages of choosing this type of valve:

Additionally, here you have the datasheet for our 3-piece valves.

I’m sure many of you have thought of the following question: This information is great, but which one should I choose?

The choice of valve depends on your needs, for example:

Another example might be:

Luckily, here at Redfluid, we offer both solutions in different sizes and materials to suit your specific needs.

And remember, for any fittings, valves, piping, or tubing, don’t hesitate… Redfluid is your best option! Feel free to contact us with any questions.

Share this post

Imagine you’re running an industrial plant and you’ve got a diaphragm seal protecting a pressure transmitter. Over time, the process fluid starts leaving deposits and

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to