Flushing Ring: the key to cleaning and calibration without disassembly

Imagine you’re running an industrial plant and you’ve got a diaphragm seal protecting a pressure transmitter. Over time, the process fluid starts leaving deposits and

One thing we are often asked by customers when purchasing a rotameter is for a needle valve. You might be wondering, why are needle valves needed before installing rotameters? Stick with me, and I’ll explain in under 5 minutes.

Rotameters are devices used to measure the flow rate of fluid circulating through a system – essentially, they are a type of flow meter – that sits within a vertical tube without occupying its full diameter, thus allowing the fluid to pass through. The rotameter will rise based on the physical properties of the fluid such as density and viscosity.

At a certain point, the piston will stop ascending, and it is at this precise point that the measurement is taken, indicating the specific flow rate in that section.

Some of the most well-known brands in rotameter manufacturing include Yokogawa, Tecfluid, Emerson, Siemens, ABB, Brooks, and Asa. Our needle valves are compatible with both flanged and threaded rotameters from these brands.

Now that we’ve covered the rotameter, let’s look at the other part of this equation: the needle valve.

A needle valve is a device used to regulate fluid flow within a system. This specific type of valve can regulate fluid flow with high precision due to its shut-off mechanism.

Needle Valve: Before or After the Rotameter?

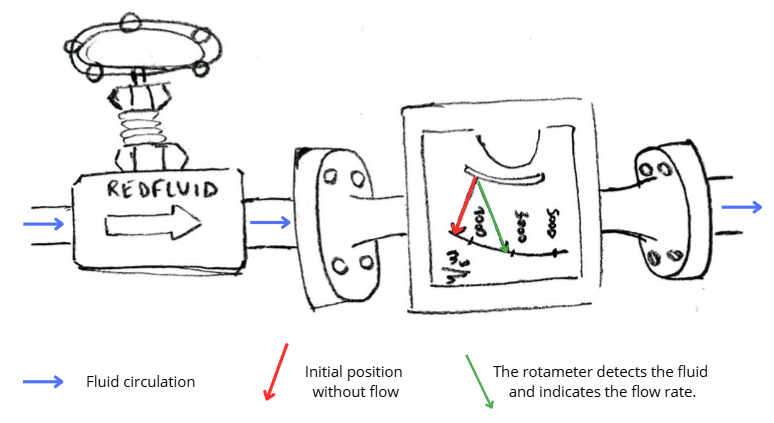

In most cases, the needle valve is installed before the rotameter, which in engineering is called “Upstream.” This setup offers several advantages:

It’s true that in some installations, needle valves are installed after the rotameter, but this is less common.

Needle valve installed upstream or downstream?

Let’s break it down:

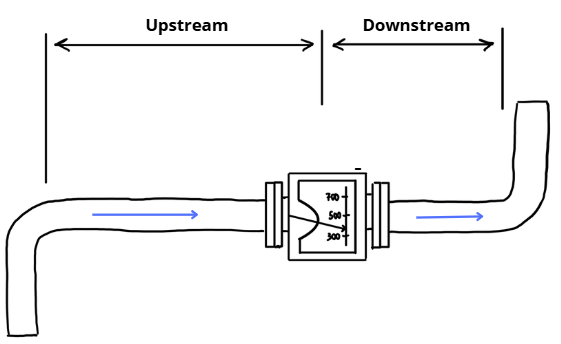

First, what does the term “upstream” or “downstream” mean?

Simple—it refers to the position relative to the rotameter installation. Upstream means the section before the rotameter, while downstream is the opposite, meaning the section after the rotameter installation.

At Redfluid, we offer all types of needle valves you may need, in various sizes and specific materials ideal for your rotameter, whether for gases or liquid fluids.

Here’s the link to our needle valve catalog.

And now, it’s time to bring these two worlds together and answer the question we posed initially. Without further ado, let’s go!

The reason why it’s important to place a needle valve before a rotameter is to protect it from water hammer. And you might be wondering, what is water hammer? Well, it’s simple—it occurs when a moving fluid stops or changes direction suddenly or “heavily,” causing a sudden jolt.

This change in movement would lead to a significant increase in pressure, which would likely—almost certainly—result in damage to the instrument and cause serious impacts to the piping system.

Moreover, the combination of a needle valve and a rotameter is very useful for controlling flow rate. In other words, as you gradually adjust the flow using the needle valve, you rely on the rotameter to measure that value and achieve an even more precise adjustment.

At Redfluid, the solution we propose is the following:

I hope this has helped you understand a bit more about how a rotameter and a needle valve work, and especially the importance of combining both devices. If you have any questions, don’t hesitate to get in touch with us!

And remember, for any issues related to fittings, valves, tubing, or piping, we at Redfluid will be delighted to help!

Share this post

Imagine you’re running an industrial plant and you’ve got a diaphragm seal protecting a pressure transmitter. Over time, the process fluid starts leaving deposits and

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to