What is a condensate pot and what types are there?

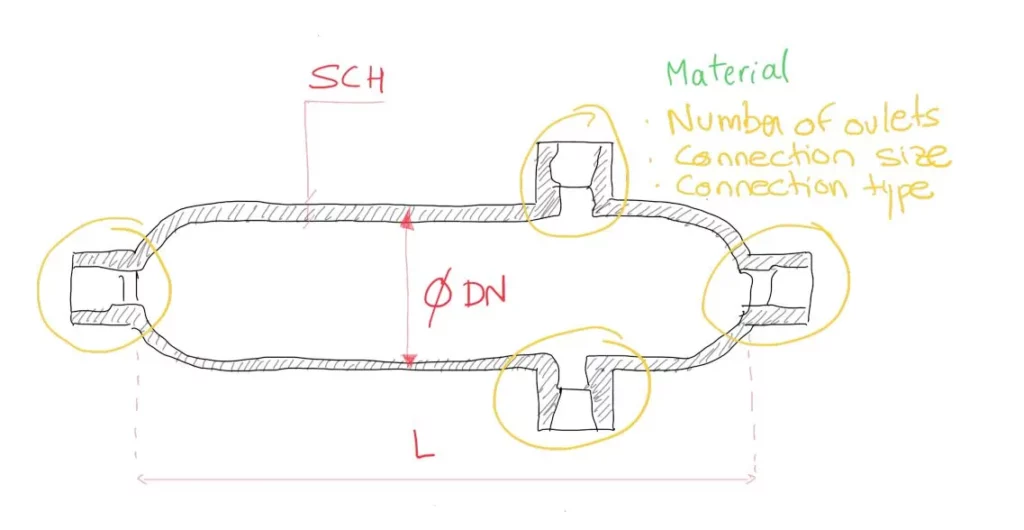

Let’s see. First of all, it is necessary to make a sketch of what we are talking about. We have different names for condensate pot

Maybe this is the question you’re asking yourself, and you feel the need to understand what condensate pots or barrel pots are and which one you need. Or maybe you just want to be more informed.

Either way, don’t worry. After reading this blog, you’ll be the condensate pot expert in the office.

To complement this article, you can read more about pots and how they differ from manifolds or distributors in this post.

Or if you prefer… Here’s a video where I explain everything in just 3 minutes!

Let’s start by explaining what a condensate pot is, in simple terms: A condensate pot is a key component in many power plants, thermoelectric plants, and combined-cycle plants.

If you’re working with high-temperature or high-pressure steam and measuring differential pressure—or using any other instrument—this small metal piece can save you from a looooot of trouble. Because yes, if steam reaches the transmitter or instrument directly… you can say goodbye to the transmitter and hello to the thousands of euros you’ll be spending on repairs, replacements, and maintenance.

To understand it fully, the barrel pot retains the steam condensate and maintains a liquid column between the process and the transmitter or instrument.

Why is that important? Because that column acts as a thermal shield, preventing direct contact between the working temperature and the transmitter. It’s installed close to the transmitter and has no moving parts—meaning very low maintenance.

But watch out—you need to know what material and wall thickness to request.

For high-temperature operations, you’ll need to select special materials for condensate pots. At temperatures around 550 °C or higher, you’ll require high-temperature-grade steels such as:

These materials comply with ASTM A335 or ASTM A182 standards for the forged version. Sometimes they’re also referred to as ASME SA182, but that’s exactly the same as ASTM A182.

Condensate pots are made from standard pipe, but the Schedule determines how much pressure they can handle.

Example:

So, very important: Before ordering your condensate pot, make sure the schedule matches the pressure you need.

This must be calculated case by case, since as temperature increases, the pressure resistance of the pot decreases.

At Redfluid, we usually handle this calculation using ASME Section VIII Div.1 for services up to 3000 psi and ASME Section VIII Div.2 for pressures above 3000 psi.

As for connections, we adapt to your needs. They are usually male or female threaded (NPT or BSP), but we also manufacture pots with welded connections (SW or Butt Weld) when required.

If you need a custom build with flanges, compression fittings or other types of connections, just let us know and we’ll implement it in your project—sometimes we even supply them with valves on the ends.

Well, these barrel pots, air manifolds, condensate pots—or whatever you want to call them—are very common in power generation industries, such as:

If you spot a differential pressure transmitter measuring steam… there’s about a 95% chance there’s a pot nearby, quietly doing its job.

The other 5%? Those are people who still need to buy one—and are reading this blog to get it right 😉

We also offer zinc-plated finishes for medium-to-high temperature services, which provide a bright silver appearance and excellent corrosion resistance.

And for extreme temperature services, we can apply special high-temperature coatings to ensure long-term performance.

The standards are the usual ones for this type of equipment, buuut in case you’ve forgotten, here’s a quick reminder:

A condensate pot is affordable, robust, and protects your sensors.

At Redfluid, we custom-build them with the material, schedule, and connections you need.

If you have any doubts, just reach out—send us the pressure, temperature, and line material, and we’ll handle the calculations and manufacturing without hassle.

We take care of the pot. You make sure the plant keeps running like clockwork.

Share this post

Let’s see. First of all, it is necessary to make a sketch of what we are talking about. We have different names for condensate pot