Hydrogen Check Valves

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to

Imagine you’re running an industrial plant and you’ve got a diaphragm seal protecting a pressure transmitter. Over time, the process fluid starts leaving deposits and buildup on the membrane, causing inaccurate readings.

How do you avoid taking the whole assembly apart every time you need to clean or calibrate it?

A simple flushing ring.

In this article, we’ll walk you through what a flushing ring is, what it’s used for, how it’s installed, and the different options available. You’ll also find a video where you can see it in hand and understand its uses at a glance.

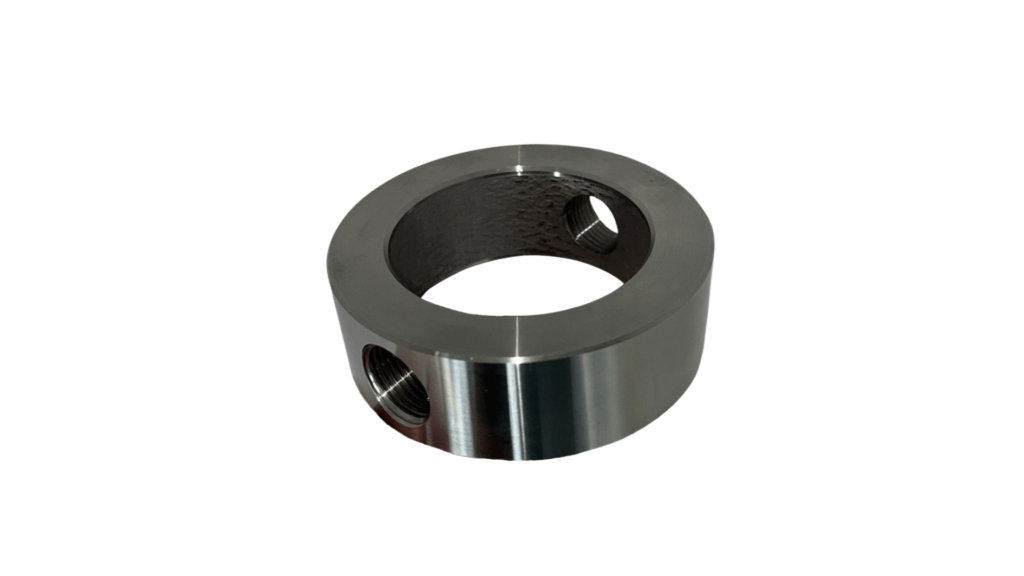

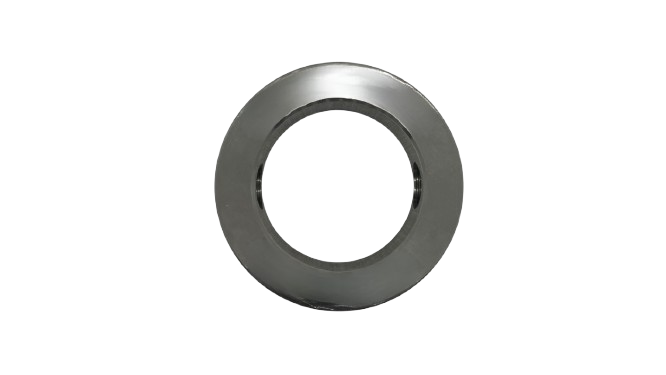

A flushing ring is a circular accessory designed to be installed between the process flange and the diaphragm seal of a pressure instrument.

In other words, it works like a special gasket placed between the pipeline flange and the diaphragm seal of a gauge or transmitter. The ring usually has the same diameter and bolt pattern as the flange, so it sits sandwiched in the connection without altering the normal assembly.

It’s manufactured with a defined thickness (typically around 30 mm) to house one or two lateral purge ports and to accommodate standard sealing gaskets.

The term flushing ring comes from its main purpose: flushing means washing or purging the inside of the line or the space in front of the diaphragm. In Spanish, anillo de purga describes its function perfectly: it’s a ring that allows you to purge, drain, or clean without disassembling the instrument. Its construction is simple but robust, capable of withstanding the same pressure and temperature conditions as the flange where it’s installed.

In short, a flushing ring is a passive yet extremely useful component in industrial instrumentation systems that use diaphragm seals.

A flushing ring has three main uses in industrial instrumentation:

Draining and purging the line:

It allows you to flush the process line to avoid deposits and blockages. By opening its ports, you can drain trapped fluids or inject a flushing medium that removes sediments. This is especially useful in processes with viscous, dirty, or crystallizing fluids, as it prevents buildup in the area right in front of the diaphragm.

Cleaning the diaphragm:

It makes it easy to remove deposits on the diaphragm of the seal. Through the flushing ring, you can inject a solvent, steam, or pressurized water that cleans off any buildup—without removing the transmitter. Eliminating these deposits prevents measurement drift or errors caused by accumulated dirt.

In-situ calibration of the instrument:

It enables calibration of the measurement point once the process is isolated. If you have a shut-off valve in the line and valves on the flushing ring itself, you can calibrate the transmitter in the field by injecting a reference pressure through the ring. In other words, with a flushing ring equipped with valves—and after closing the upstream process valve—you can apply a calibration pressure directly to the instrument without disassembling it, allowing you to verify or adjust the calibration in place.

In summary, the flushing ring is used to easily drain, clean, and calibrate pressure measurement systems. All these functions are performed without disassembling the instrument or significantly interrupting the process, saving time and improving safety.

Installation of a flushing ring is straightforward and is done when mounting the transmitter (or gauge) with a diaphragm seal onto the process flange:

It’s worth noting that the “G” thread can be installed on one or both sides of the flushing ring.

As we’ve seen, flushing rings are relatively simple components, but there are different configurations and options to match each application. Here’s a summary of the main characteristics of the flushing rings offered by Redfluid:

Flushing rings are manufactured to fit both metric flanges (DIN/EN standards) and imperial flanges (ASME/ANSI standards). This means there are rings available for all common nominal diameters—typically from DN25 to DN125 in European standards, and from 1″ to 5″ in American standards. Their design follows the dimensions specified in ANSI B16.5 or DIN EN 1092-1, ensuring full compatibility.

The ring thickness is usually around 30 mm (similar to an intermediate spacer) to allow proper tightening with standard gaskets.

To illustrate, here are some typical sizes of standard flushing rings:

| Flange DIN (EN 1092-1) | Flange ANSI (ASME B16.5) |

|---|---|

| DN25 | 1″ |

| DN40 | 1½” |

| DN50 | 2″ |

| DN80 | 3″ |

| DN100 | 4″ |

| DN125 | 5″ |

(Other larger nominal sizes are available on request, including DIN/ANSI flanges in bigger diameters or higher pressure ratings.)

In terms of pressure, a properly designed flushing ring withstands the same class or PN rating as the flange where it’s installed.

Redfluid’s standard models cover everything from PN10 to PN100 (equivalent to ANSI Class 150 to 600), depending on the size.

If your application requires it, we can also manufacture special rings for higher-rating flanges (for example Class 1500/2500 or PN250/PN400), ensuring full safety even in very high-pressure systems.

All flushing rings include at least one threaded lateral purge port, as mentioned earlier. This port is normally supplied closed with a screw or threaded plug to ensure tight sealing when not in use. Depending on your needs, we offer different configurations:

For more technical information and available dimensions, you can download the flushing ring datasheet here:

Using flushing rings in your measurement systems with diaphragm seals can provide major benefits in maintenance, accuracy, and cleanliness:

We know that in industrial instrumentation every detail matters to keep your processes under control. If you’re working on a project where you need flushing rings, or you simply want to make sure you’re choosing the right one for your equipment, feel free to reach out.

At Redfluid we can help you select and supply the flushing ring that best fits your operating conditions: fluid type, flange diameter, material, service pressure, and more.

Share this post

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to

You’ve probably heard about high-temperature or cryogenic valves, the ones that are incredibly resistant because they operate under extreme conditions. But what makes them so