Flushing Ring: the key to cleaning and calibration without disassembly

Imagine you’re running an industrial plant and you’ve got a diaphragm seal protecting a pressure transmitter. Over time, the process fluid starts leaving deposits and

Many times, clients ask me, “Hey Kike, do you have a valve that can replace globe or control valves?” Of course, we do!

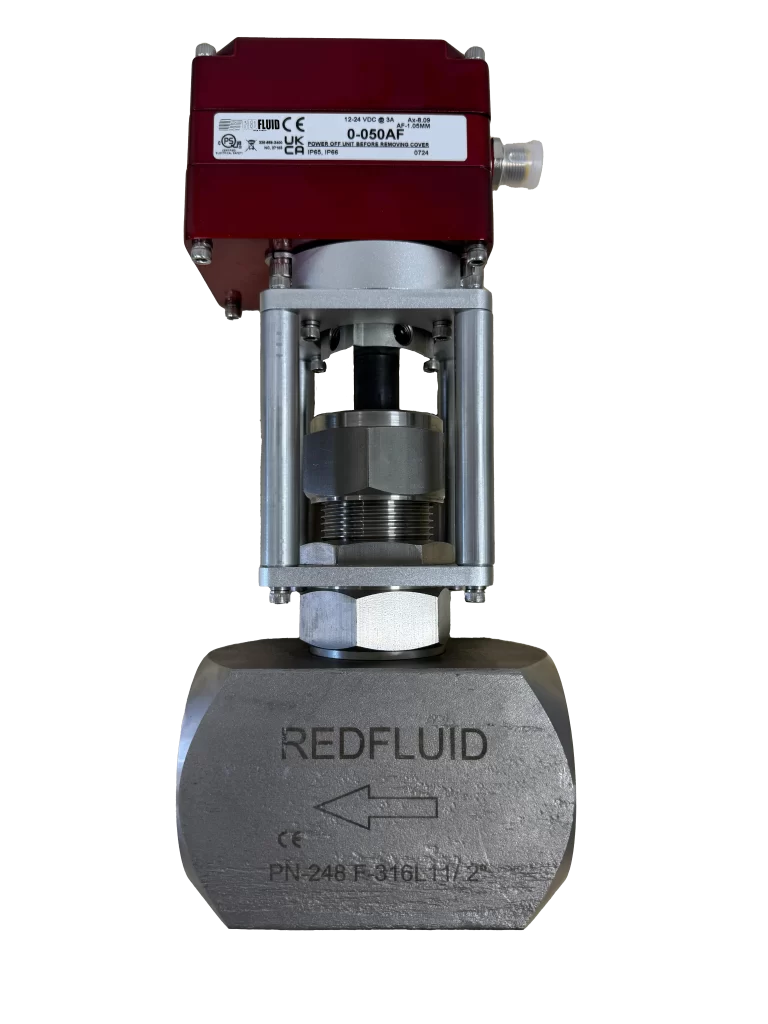

But can a needle valve be automated? Yes, yes, and yes!

For these situations, our needle valves with electric actuators are the perfect solution.

This combo allows for very precise flow adjustments because it combines the accuracy of a needle valve with the added precision of an electric actuator. This makes it ideal for applications where the flow control needs to be extremely fine.

They are also a great match because they are perfect for working with high pressures and small diameters.

Here’s a video where I explain, in just 3 minutes, how our needle valves with electric actuators work:

On the other hand, let’s talk about electric actuators… There are so many and they’re all so different: on/off types, modulating ones, proportional control… The truth is, the world of electric actuators is incredibly vast. Plus, as a standard feature, they often include automatic end-of-travel detection.

But don’t worry 🙂

At Redfluid, we’ll take care of selecting the electric actuator that works best for your specific case.

The concept involves a needle valve equipped with a multi-turn electric actuator. Using a PLC, you can command it to open, close, or adjust incrementally based on a signal, gradually fine-tuning the valve’s position to regulate the fluid flow accordingly.

But most importantly: before requesting an electrically actuated needle valve, make sure the installation area is an ATEX zone (explosive atmosphere) and let us know. We’ll handle selecting the appropriate electric actuator that complies with all ATEX regulations.

Additionally, we offer emergency battery systems that, in case of a fire, will send a signal to automatically open or close the valve.

At Redfluid, we offer needle valves that can be electrically actuated in sizes ranging from 1/8″ to 2″, ensuring exceptional flow control even in high-pressure applications. This size range covers everything from small, precise applications to more robust industrial systems.

We also provide flanged needle valves that can be electrically actuated. These valves are ideal for pipeline systems with larger diameter and pressure connections, ensuring a robust and secure installation. (Here is a link to a video where I explain how to order flanged needle valves.)

We offer various control options, including analog signals (4-20 mA, 1-5 V, 1-10 V), Modbus RS485, and TTL. This versatility makes it easy to integrate the actuators into different industrial automation systems.

Needle valves with actuators can operate with 12-24 VDC Max 3A or 110-240 VAC Max 1.5A @ 50/60 Hz. They also offer customized options for power, control, enclosures, and safety features. This flexibility allows them to adapt to the specific needs of each application.

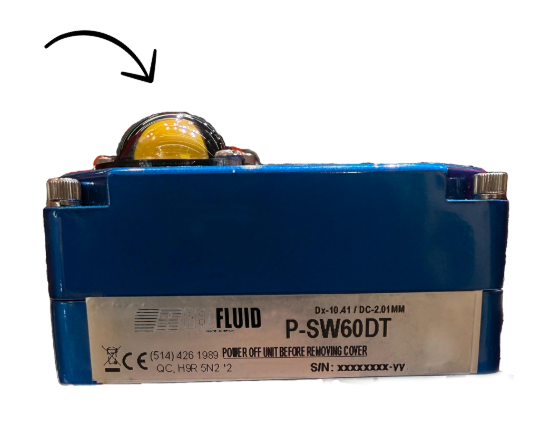

An optional dome-style position indicator can be installed on our electrically actuated needle valves.

What does this mean? You can now easily see from the outside, at a glance, whether the valve is open, closed, or in any intermediate position—even from tricky angles or at a distance. And all of this without losing the compact design that defines our valves.

This new low-profile, ergonomic indicator is perfect for those working in processes where every detail matters. According to Chris DePalma, our technical sales expert:

“Being able to visualize the valve’s actual position from any angle is an incredible advantage for process technicians and field engineers.”

Now you might be thinking: “That sounds great, but let’s cut to the chase.”

A clear example would be the chemical industry. In control and mixing systems, millimeter precision is essential to ensure the desired reaction occurs without unwanted by-products.

Another classic example is the Oil & Gas industry. In this sector, working under high-pressure conditions and managing critical measurement scenarios in processes make our solution stand out.

I hope this blog has helped answer your questions. Remember, for anything related to fittings, valves, or tubing, don’t hesitate to reach out to us!

Share this post

Imagine you’re running an industrial plant and you’ve got a diaphragm seal protecting a pressure transmitter. Over time, the process fluid starts leaving deposits and

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to