Flushing Ring: the key to cleaning and calibration without disassembly

Imagine you’re running an industrial plant and you’ve got a diaphragm seal protecting a pressure transmitter. Over time, the process fluid starts leaving deposits and

To actuate a ball valve, they typically have a handle, and to open or close them, you have to do it manually. But how do we do it if we want to automate this process so the valve opens or closes according to computer instructions? That’s where actuation comes in. We install an actuator.

An actuator is a device that allows the valve to open or close. Depending on the energy it uses, the actuator can be electric, if it is plugged into electricity, or pneumatic, if it uses compressed air to move the valve.

It often happens that we want to rush and get things done as quickly as possible. But the one who runs the fastest is not always the one who gets the farthest. So, pay attention.

Let’s talk about pneumatics.

First, there are two types:

IMPORTANT! When you order a single-acting pneumatic actuator, you must specify if you want it normally closed or normally open. This will be the default position in the absence of air.

Single-acting actuator: always remember to specify if you want it Normally Open or Normally Closed.

Next step!!!

If we are clear on whether we need a double-acting or single-acting actuator, we need to select the size of the actuator.

Normally, the following rule is used:

Opening torque of the valve in Newton Meters x FS

FS, or Safety Factor, varies depending on the fluid. At Redfluid, we use the following:

With this, we will have the size in NM of the actuator we need. Be careful, because for SINGLE-ACTING actuators, the formula is not the same. You have to take into account the force of the springs. They must have enough force to close and open the valve.

Tip: For single-acting actuators, larger sizes are always needed compared to double-acting actuators, because the springs must have enough force to open/close the valve. Additionally, you must indicate the air line pressure that feeds the actuator to select the single-acting type. Typically, 6 bar is considered.

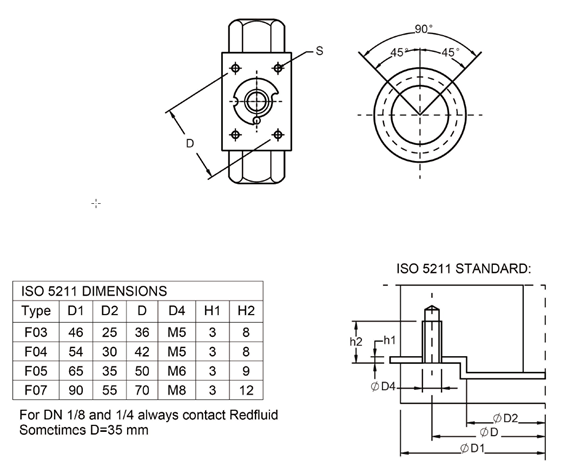

How do we attach the actuator to the valve? There is a standard that unifies this, and all manufacturers and actuators use the same one: ISO 5211. This drilling pattern tells us the distance between the screws that will secure the valve and the actuator. Each distance has a different arrangement.

It is actually quite basic. You need to check the drilling arrangement of the valve and the actuator. If they have the same pattern, you simply connect them. And if they don’t have the same pattern, it’s not a problem either. At Redfluid, we connect them with a type of structural adapter, and… problem solved!

For example, according to the ISO 5211 table, an F05 type arrangement has a hole distance of 50 mm. In summary, you must check that if the valve is F05, the actuator must also match and be F05.

Tip: The actuator and the valve must always have the same ISO 5211 hole pattern. But be careful! Sometimes extra accessories like conversion adapters or structural components are needed to assemble the actuator.

As you well know, Redfluid valves can be requested as ATEX.

If you are looking for a complete ATEX solution to be installed in explosive atmospheres, the actuator and all its accessories must also be ATEX. Therefore, you need to specify which ATEX Zone you actually need, as this will determine whether the solutions are more or less economical.

Usually, when an actuated valve is needed, other accessories are also required. Each of them serves a different function. In this case, we are talking about:

It might seem a bit confusing, but it’s not too complicated. Let’s go step by step

And what is a positioner?

A positioner is a device that not only allows you to open/close the valve but also lets you specify “I want you to open the valve only 20%” or “open or close the valve to a specific percentage based on a signal.” The positioner is usually associated with ball valves or control valves, called “V-ball” valves. It’s not the most common requirement, so if you’re unsure if you need it, you probably don’t.

Do you know when you go to the fair and there’s that typical noisy ride that makes the air sound pxxxt, pxxxt, pxxxt? That’s what you’ll hear if the control valve doesn’t have silencers. It’s a very simple but effective device to mitigate noise in the plant.

Connection Fittings for Actuators

These are quick-connect fittings, type Push In, for flexible compressed air tubing. If you’re looking for a fully plug-and-play solution, don’t forget to add the fittings so everything arrives assembled and ready to go. They are usually for tubing with an outer diameter of 6 or 8 mm and come in straight or elbow shapes.

What Finishes Can My Actuator Have?

We can select other finishes such as an epoxy-painted housing for saline, corrosive environments, and water treatment industries. You can also request a special finish for the chemical, beverage, or pharmaceutical industries. There are also special actuators for high temperature or, conversely, for working in temperatures as low as -50°C. In summary, whatever you need.

Actuation Valve or SOLENOID

This valve is an accessory that allows us to control the actuator’s air supply through an electrical signal from the PLC. It is also called an electrovalve, solenoid valve, pilot-operated valve, or NAMUR valve. Though NAMUR is actually the name of the screw connection pattern between the actuator and the electrovalve.

This valve has many configurations, but you should basically focus on:

Our solenoid valves have a special protection in the spring chamber that ensures only compressed air is used, preventing atmospheric air from being drawn in. This extends the valve’s lifespan by protecting the springs against environmental corrosion.

Sensor Box or Limit Switch Box

This box contains sensors that verify the position of the valve. It is a secondary control that indicates whether the valve is open or closed. In automation engineering, this is known as feedback or “closing the loop.”

There are many versions of these boxes depending on the type of sensor you want to install:

Additionally, there are different types of operating voltage (24V DC, 8.2V DC, 250V AC, 110V AC).

ATEX or IECEx Option: Be careful, as the ATEX zone determines the necessary configuration.

Here we see a diagram with all the installed components:

Coordinating the entire process of actuating ball valves is no easy task. From selecting the right actuator to ensuring that the accessories match and function correctly, every step is critical.

An error in torque calculation, an incompatibility in the ISO 5211 drilling pattern, or an incorrect ATEX configuration can result in serious failures, leaks, and potential safety risks. That’s why we strongly recommend contacting us. At Redfluid, we offer comprehensive, plug-and-play solutions that are assembled and tested so that you only have to connect and plug them in, ensuring a safe and efficient installation.

Share this post

Imagine you’re running an industrial plant and you’ve got a diaphragm seal protecting a pressure transmitter. Over time, the process fluid starts leaving deposits and

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to