NPT Swivel Nut: How to Achieve Rotating Connections with a Tapered Thread

Imagine you’re installing a pressure gauge on a pipeline and, as you screw it in, you realize that when it finally tightens… the dial is

Sounds familiar? The technician looks for a fitting, maintenance can’t find it, purchasing places an urgent order “for yesterday”… In the end, production gets delayed, you overpay, and the whole just-in-time thing never really works.

Don’t worry — you’re not the only one.

The good news? There’s a solution.

Here’s a short video that shows you everything in just 3 minutes!

Since the rise of Just in Time, nobody wants to keep stock of anything. But the reality is that it often turns into chaos — especially with small consumable parts that should always be within reach. You’re halfway through an assembly, realize you need one, and of course… it wasn’t planned. Then the rush begins:

At Redfluid, we’ve developed a simple yet highly effective way to bring order to your stockroom: a cabinet or shelving system custom-designed to fit your needs, stocked with the components you actually use. But we’re not just talking about furniture.

We’re talking about a visual management system for your consumables and critical components — designed so your storage works for you, not the other way around. Every part has its place, its label, and even a defined reorder level if you want it. This way, your team gains autonomy, and you regain control without having to spend hours on supervision.

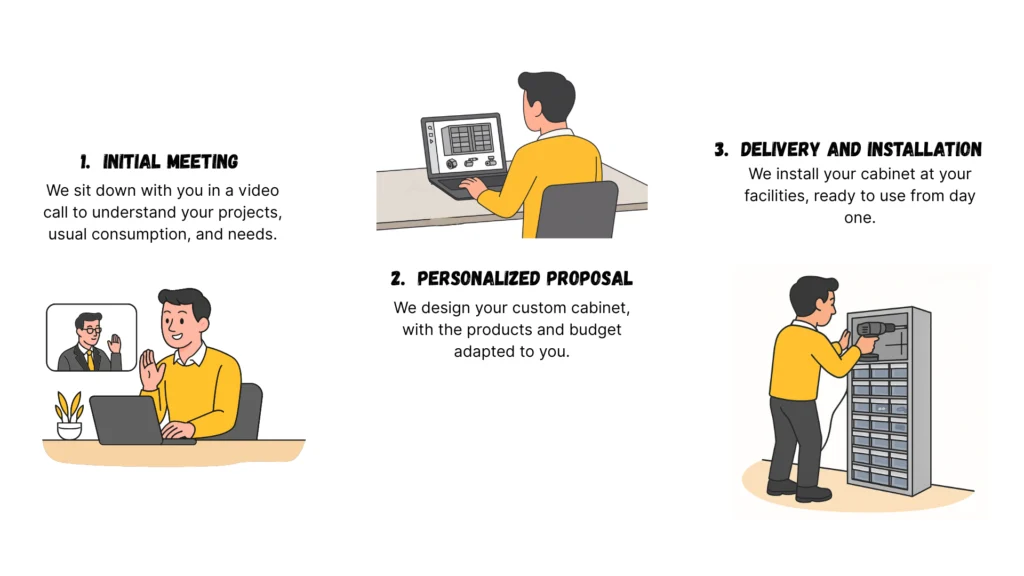

The process to implement this system is simple and fast:

In addition, depending on the size of the project, the cabinet or shelving system could even come at no cost to you…

It can include:

Each compartment is tailored to the type of part and the right quantity — so you never end up with too much or too little stock.

Every cabinet is configured according to your needs and type of application.

And if you want, we can even customize it with your company’s logo, so it fits perfectly into your workspace with a professional, brand-consistent look.

If you want, we can define a minimum stock level using a simple Kanban card system. Inside each container, there’s a small bag with the last few pieces and a red Kanban-style card that appears when that bag is opened. This card includes a unique QR code that lets you reorder parts, check the reference, and see the description. That way, you avoid stockouts without having to manually check every item.

It’s a simple, visual, and efficient system, inspired by Lean Manufacturing principles, ensuring your minimum stock is always up to date.

We don’t do this project alone. At Redfluid, we believe in partnerships that bring real value. That’s why we collaborate with a partner specialized in industrial storage systems and Lean organization.

They design and manufacture the custom cabinet; we equip it with our products, define the replenishment system, and ensure full traceability and availability of all components.

The result is an integrated and exclusive solution, developed together and tailored to each customer. A professional system with one major advantage: it’s always designed around your way of working.

This system allows you to:

Want to see what yours could look like? Fill out this form and we’ll help you design your own system

Share this post

Imagine you’re installing a pressure gauge on a pipeline and, as you screw it in, you realize that when it finally tightens… the dial is

What is Type Approval for marine and offshore components, and why does it matter? Type Approval is a certification process by which a classification society