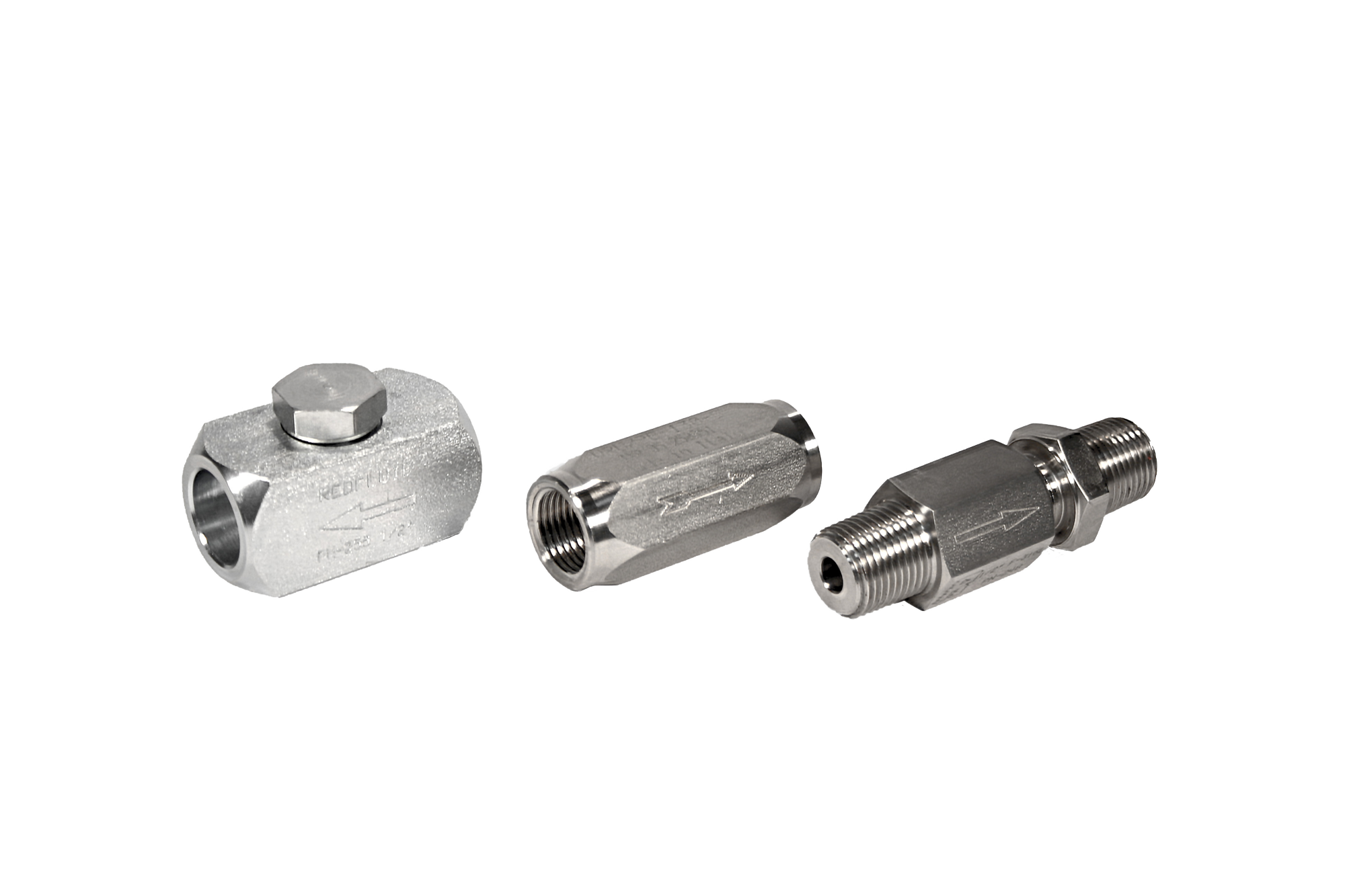

Check valves

Check valves, also known as one-way valves, non-return valves, or single-flow valves, are designed to allow fluid to flow in one direction while preventing it from flowing in the opposite direction, thereby eliminating the effect of backpressure in hydraulic and pneumatic systems.

These valves are ideal for instrumentation applications, where preventing backflow is crucial to maintaining the integrity of the system and the associated instruments.

Redfluid check valves operate through an automatic closing system using a spring piston, ensuring an effective and fast seal when fluid tries to flow back. This design allows free fluid flow in one direction and efficient blockage in the opposite direction, eliminating the effect of backpressure in the circuits.

Redfluid offers various series of check valves to meet different pressure and application needs:

The valves are available in a variety of materials, including carbon steel, stainless steel 316/316L, brass, duplex, super duplex, hastelloy, and monel, among others. Connections can be NPT (ANSI B1.20.1), BSP, or cylindrical GAS (ISO 228, DIN 259), SW (ANSI B16.11); BW, SW OD, flanged, or mixed, adapting to the specifications of each installation.

One of Redfluid’s most innovative solutions is the check valve with adjustable opening pressure. This valve allows you to easily adjust the cracking pressure directly at the work site using just an Allen wrench—no need to change springs or perform complex adjustments. This feature not only adds flexibility but also saves time, especially in applications where pressure conditions can vary.

To learn more about this innovative feature and how it can benefit your system, be sure to read our detailed article on the subject.

Read the Full Article on Adjustable Opening Pressure

If you need more help or have any questions, feel free to contact us!!

Our team will be happy to assist you in finding the best solution for your needs.

Do you need more info? Here you can download the technical datasheet of this product.

Different series depending on the required service pressure, up to 4140 bar.

For lines from 1/8 to 4 ”diameter.

NPT (ANSI B1.20.1), BSP or Cylindrical GAS (ISO 228, DIN 259), SW (ANSI B16.11); BW, SW OD, Flanged, Mixed.

Carbon Steel, 316 / 316L Stainless Steel, Brass, Duplex, Super Duplex, Hastelloy, Monel, among others.

The piston can make the metal-metal closure (only by high pressure) or with an O-ring. The piston closure can be with compensation spring or free (only in horizontal position).

If you need other connections, materials, special O-rings or other modifications, we can tailor it for you. Place your order here.

Redfluid check valves are used in instrumentation, hydraulic or pneumatic application systems. These valves are characterized by allowing fluid to pass in one direction but not in the opposite direction.

The circuits are not designed to be able to accept a liquid backflow. Most valves can fail if used incorrectly and that is why the Redfluid check valve is a solution to prevent backflow— Using a piston a check valve prevents the fluid from going in one direction but not the other will avoid damaging the instruments in your installation.

Redfluid check valves are a reliable solution and are very easy to maintain. Requires no manual adjustment and returns to its original position when pressure is released.

Do you need more info?

If you wish, you can also contact us to ask for more information or place an order: