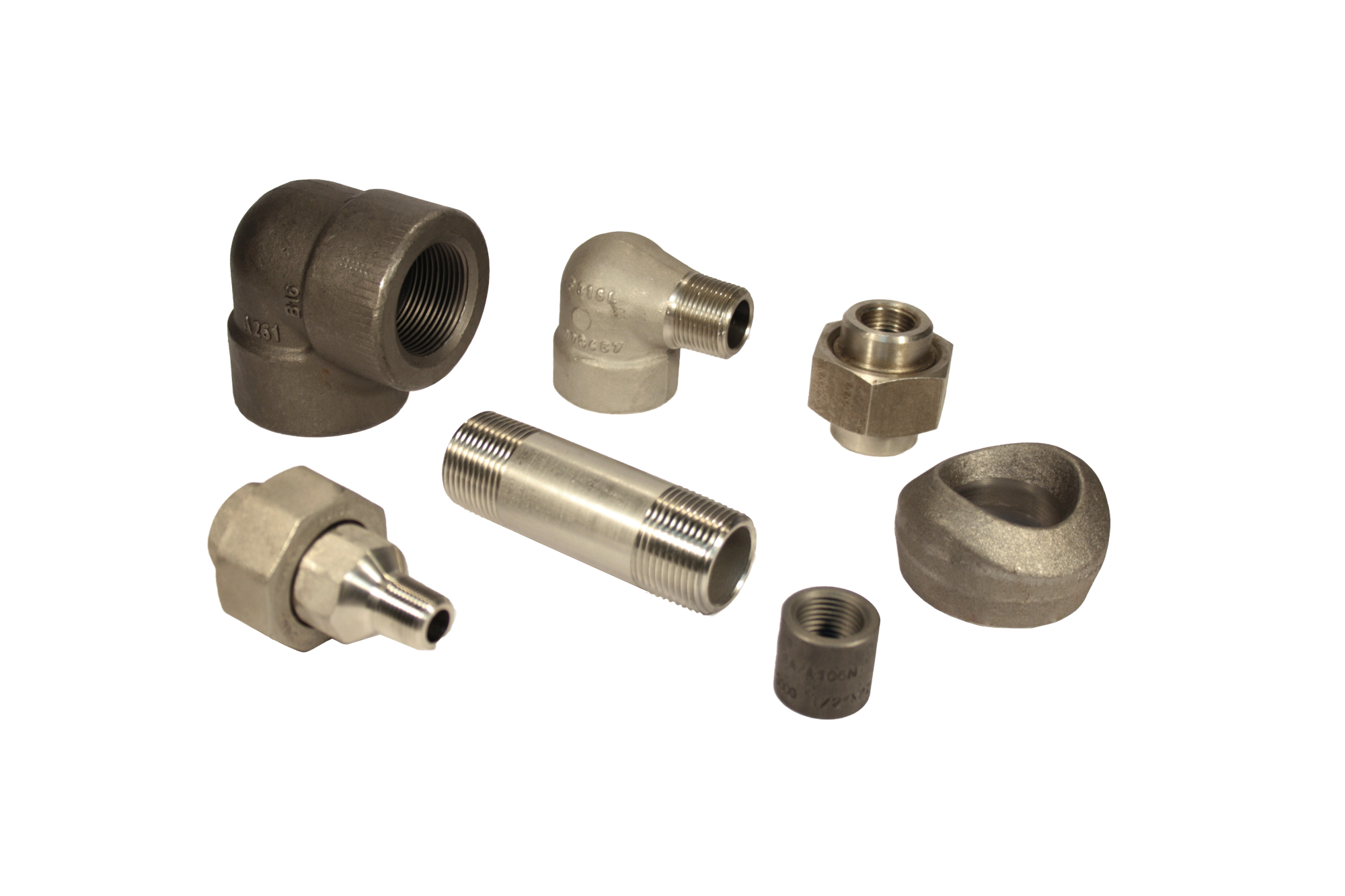

ASME B16.11 fittings are Pipe Joint Sleeves, Elbows, TEEs, Crosses to connect normally SCH pipes.

They are bar or forged fittings and can have threaded connections: BSP, NPT or welded: SW (Socket Weld) and BW (Butt Weld).

Do you need more info? Here you can download the technical datasheet of this product.

Different series depending on the pressure of service:

3000 PSI, 6000 PSI or 9000 PSI

For lines from 1/8 to 6 ”diameter.

NPT (ANSI ASME B1.20.1), BSP, BSPT or Cylindrical GAS (DIN 259, ISO7 / 1, 228-1 10226-1), SW (ANSI ASME B16.11); BWASME B16.25, SW OD, Flanged ASME B16.5 – RF / RTJ – API 6A / 6BX, Mixed.

Carbon steel, Stainless steel 316 / 316L, Latón, Duplex, Superduplex, Hastelloy, Monel, among others.

Black, Zinc Plated, Galvanized, Passivated

SCH10, SCH80, SCH160, SCHXXS.

The fittings and accessories are standardized, but not all manufacturers or materials are the same. Our products have been used in a multitude of installations throughout 30 years in the oil and gas industry.

A105.N – A106.B (HOT DIP GALVANISED, ELECTROPLATING).

A350: LF2, LF3, LF6.

A694: F42, F52, F60, F65, F70.

P280GH and P245GH according to EN10222-2

STAINLESS STEELS:

A182 F 304/304L, 304H, 310, 316/316L, 316H, 316Ti, 317L, 347/347H, 321/321H, F20, F44, F904L.

LOW ALLOY: A182: F5, F9, F11, F22, F91.

FERRITIC – AUSTENITIC STAINLESS STEEL :

DUPLEX : F51 / F60; SUPER DUPLEX : F53/F55.

NICKEL ALLOYS:

INCONEL : 600 – 625 – 718.

INCOLLOY : 800 – 800H – 800HT – 825.

HASTELLOY: B2 – B3 – C22 – C276 – C2000.

MONEL: 200/201, 400, K500.

CARPENTER 20CB3 – ALLOY 20 – UNS N08020.

OTHERS :

TITANE : T40 Gr 2 – UNS R50400

Cu-Ni 90/10, 70/30 / Cupronickel

BRONZE

Do you need more info?

If you wish, you can also contact us to ask for more information or place an order: