Flushing Ring: the key to cleaning and calibration without disassembly

Imagine you’re running an industrial plant and you’ve got a diaphragm seal protecting a pressure transmitter. Over time, the process fluid starts leaving deposits and

“Hey Kike, do you have a valve that can prevent my system from exploding if the pressure rises?”

Of couuuurse we do! In these cases, our relief valves are essential. In this article, I talk about relief valves vs safety valves.

Before anything else, here’s a quick video (3 minutes) where I explain, with examples and in detail, how these valves work and how to adjust their opening pressure:

This is a veeeery common mistake, and maaaany people believe that Pressure Safety Valves and Pressure Relief Valves are the same. But don’t worry, after this article, you’ll be able to confidently say you know the difference between both valves!

To introduce the topic and warm things up, I’ll briefly explain the function of both in a single sentence: releasing pressure to protect the system from overpressure.

And you might say, “then, why do you say there’s a difference between one and the other?” Don’t ruuuush, I’m coming with the differences, so let’s go!

Let’s start first with our new valves, the Pressure Relief Valves or PRV:

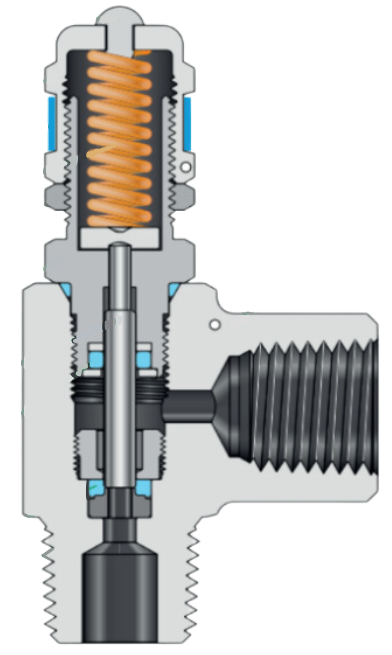

These valves are designed with an adjustable cracking pressure, which we will discuss later in the blog. When the system pressure exceeds this value, it pushes the spring and allows the valve to open PROGRESSIVELY to release the overpressure in your system. It will remain open until the system returns to safe pressure levels.

These valves are mainly used with liquid fluids.

On the other hand, they are not the most suitable for sudden and strong overpressure events due to their gradual but controlled opening.

On the other hand, we have the Pressure Safety Valves or PSV.

In this case, these valves also include an adjustable cracking pressure, which, when exceeded, pushes the spring and opens the valve. The DIFFERENCE with PRVs is that these open INSTANTLY. This type of valve is used in gas/steam systems.

Buuut they also have their weak point. Due to the rapid opening/closing, they can cause water hammer.

Water hammer is a phenomenon that occurs when a valve is closed abruptly. This generates a sudden pressure increase at the inlet and creates a fluid wave that travels in the opposite direction of the normal flow. This wave can cause serious damage to instruments or systems if not properly controlled.

These valves are perfect because they are designed to protect you in the most critical moments. That is, when the pressure rises too much—beyond the set cracking pressure—they automatically act to release the excess and bring the system back to safe levels.

It’s important to highlight that the cracking pressure is adjustable, so it can adapt to maaaany systems.

This way, you avoid serious problems, such as equipment damage or even major incidents. They’re the safety every system needs!

At Redfluid, we understand the importance of precision and reliability in these components for any system. That’s exactly why we have our own calibration laboratory, designed to ensure that all our products meet the highest standards of quality and performance.

And you might be wondering: “That all sounds great, but what do you actually do?” Great question! Here’s a quick summary:

The great thing about these valves is that:

There’s something for everyone! From the classic spring-loaded relief valves to more advanced pilot-operated options that offer much more precise control. Not to mention disc or diaphragm versions, ideal for systems that require an ultra-tight seal.

At Redfluid, we offer and recommend adjustable spring-loaded relief valves because they are versatile and perfect for a wide range of applications.

Want more details about our relief valves? Download our catalog and discover all their features and benefits!

And as always, if you have any questions about valves, fittings, or high-pressure systems, feel free to contact us! I’ll help you find the solution you need without wasting time.

Share this post

Imagine you’re running an industrial plant and you’ve got a diaphragm seal protecting a pressure transmitter. Over time, the process fluid starts leaving deposits and

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to