NPT Swivel Nut: How to Achieve Rotating Connections with a Tapered Thread

Imagine you’re installing a pressure gauge on a pipeline and, as you screw it in, you realize that when it finally tightens… the dial is

If you’ve been trying to understand what weldolet, sockolet and threadolet are but still can’t figure out what their differences are, you’ve come to the right place. Read on and I will tell you the differences between weldolet, socket, and threadolet as I would explain them to my daughter.

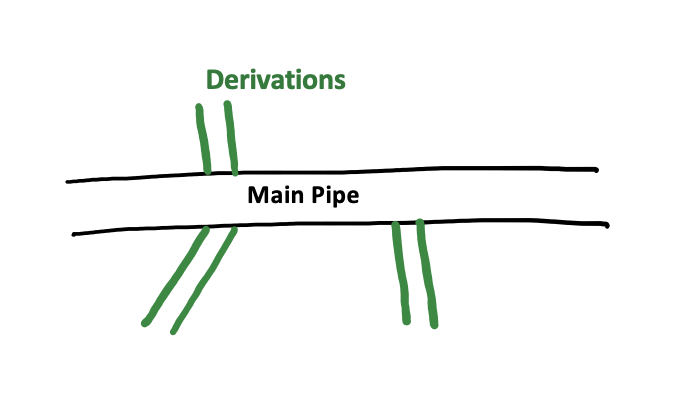

Before going into the details of each of these parts, it is important to know that they are part of a piping system and are used to make connections between the main pipe of the system and the corresponding branches of the system.

In other words, they are pieces that replace traditional connections such as elbows and TE’s for 90 and 45-degree branches.

The main features of connections such as weldolet, sockolet, and threadolet include:

Of the above features, the one that offers the biggest difference is the way they are connected to the corresponding shunt. Let’s look at each in detail to better understand what their differences are.

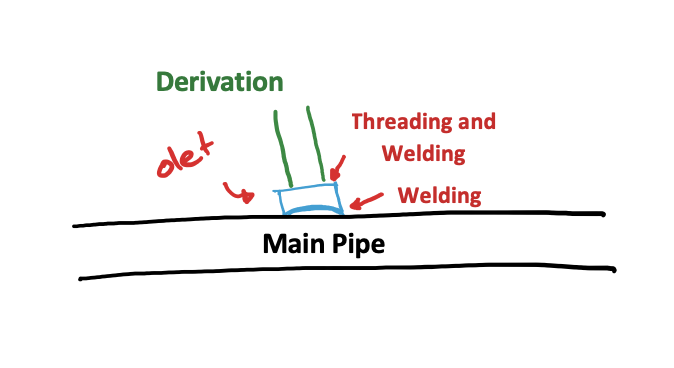

The weldolet is considered the most popular of the group and is often classified as a buttweld type connection (BW buttweld). This classification refers to its beveled outlet that is butt-welded to the branch pipe during installation.

The weldolet is ideal for replacing a tee on 90-degree branches with a reinforced connection that protects the branch pipe by reducing stress concentration due to its shape and size.

Its beveled ends allow an easy installation by BW welding on the previously cut main and on the branch pipe which will have an internal diameter or Schedule generally smaller or equal to the weldolet.

Note that in some cases a short and long radius connection at 90 and 180 degrees will be required which cannot be achieved with the weldolet.

In such cases, a part known as Elbolet is used, whose name comes from the English word “elbow” which means elbow and which allows this type of connections with butt weld or even threaded. The main applications are generally found in thermal wells and instrumentation connections.

Its name comes from the type of weld used to make the connection between the main and the branch using this piece, SW socket weld. Like the weldolet, this connection is a great alternative for TE’s in 90-degree taps.

Aside from the type of weld used, the main difference with the weldolet is that the sockolet is typically used for applications with lower pressures and smaller pipe diameters.

Although the difference is one letter, it is important to note that the thredolet is the same connection. The name suggests the main characteristic of this connection since “thread” means thread. In a simple way, it could be said that a threadolet is exactly the same as the weldolet with the main difference being that it connects to the branch pipe through a thread.

Another difference of the threadolet with respect to the weldolet is the fact that it is used in applications with much lower pressures and smaller diameters.

The thread of this type of connection is generally of the NPT type according to ASME B1.20.1 specifications.

But, if they are just an alternative, why use a different type of connection than the classic elbows and TE’s? Well, let me tell you about it.

Although most of the connections made with these alternatives could also be achieved with TE’s and elbows, the fact is that using a weldolet, sockolet, threadolet or elbolet brings a number of benefits, among which the following stand out:

At this point, it should be noted that all these connections are also classified in the group of fittings. Red Fluid offers a series of ASME B16.11 fittings for pressures of 3000, 6000, and 9000 psi.

And if you don’t think any of the standard fittings we offer to meet the requirements for your application or your customers’ needs, don’t worry, we’ve got you covered.

We have 35 years of experience manufacturing custom parts, from valves to adapters to fittings like the ones I’ve described so far. In short, if we don’t have it in stock, we make it.

If you need your part made to measure, send us the manufacturing request right now here.

If you need any of the weldolet, sockolet, threadolet, or elbolet connections, I recommend that you have the following information available when preparing your order:

With this information, you will be able to order your connections without any problem. However, if you are not sure and would like to clear up any doubts to make sure you get what you really need, contact us through this link and we will be glad to answer you within 2 working days.

Share this post

Imagine you’re installing a pressure gauge on a pipeline and, as you screw it in, you realize that when it finally tightens… the dial is

Sounds familiar? The technician looks for a fitting, maintenance can’t find it, purchasing places an urgent order “for yesterday”… In the end, production gets delayed,

One Response

Good day,

for a running project on the Lloyd Werft Germany we need some weldolets with following dimensions:

– 1x Weldolet 20“ (508×38,1mm) x 2“ (60,3×8,71mm)

– 2x Weldolet 12“ (323,9×25,4mm) x 1“ (33,4×6,35mm)

– Materialcertificate von ABS with KBV

– Material: ASTM A182 – 316 / 316L

– Standard: MSS SP 97

– Minimum Class 900

Hope to hear from you.