Flushing Ring: the key to cleaning and calibration without disassembly

Imagine you’re running an industrial plant and you’ve got a diaphragm seal protecting a pressure transmitter. Over time, the process fluid starts leaving deposits and

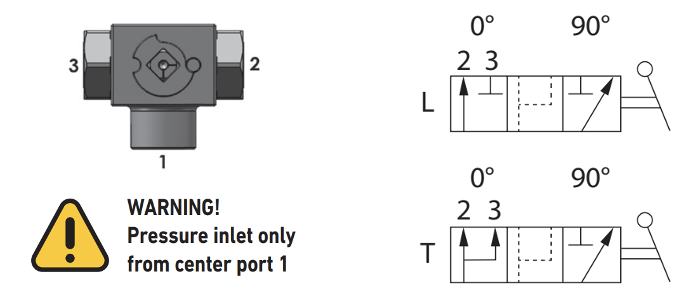

First premise: A 3-way ball valve can come in two different configurations: L or T.

In any case, they look very similar.

So… keep reading, and I’ll tell you a little about the difference because more than one has been wrong.

That is why differentiating one from the other and understanding its operation is vital to avoid problems in the application where it will be installed.

A 3-way ball valve is a type of floating ball valve. It is the most common type of valve for shutting off flow in a pipeline. It uses a perforated ball as the element to shut off the flow.

The main characteristic of a 3-way ball valve is that it has three ports instead of two. “Makes sense,” you’ll say, but it had to be said.

These ports are usually described as one inlet and two outlet ports, although in exceptional cases, it can be one outlet and two inlet ports depending on the configuration.

It has 3 ways it can control the flow passage in both configurations. In L-passage or T-passage.

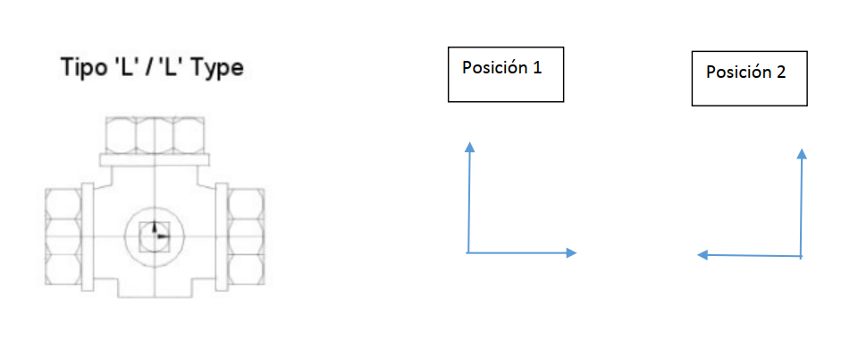

The L-passage of a 3-way valve refers to the configuration with one inlet port and two outlet ports. The valve diverts the fluid to one side or the other by entering the fluid through the center. The flow flows from the center connection port to one of the side ports, and when the 3-way ball valve is repositioned, the flow changes direction to the second side port.

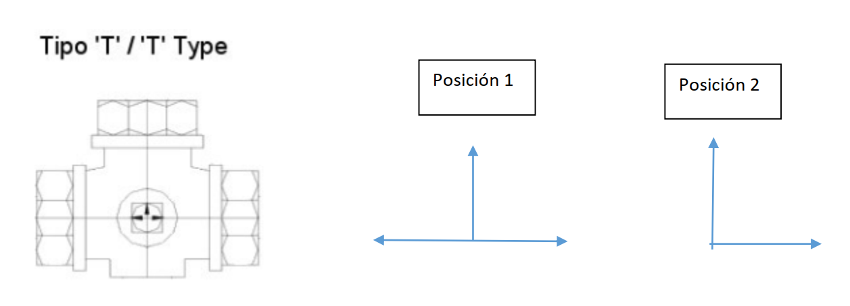

The T-passage of a 3-way ball valve refers to the configuration having one inlet port and two outlet ports. The flow flows from the center connection port and splits to the side ports. When the 3-way ball valve is changed position, the flow flows to only one side port. This is due to the closure of the other side port.

The T type thus works in 3 positions, but none of them allows the flow to be completely cut off, as all positions allow the flow to pass either to both outlets, to one or the other.

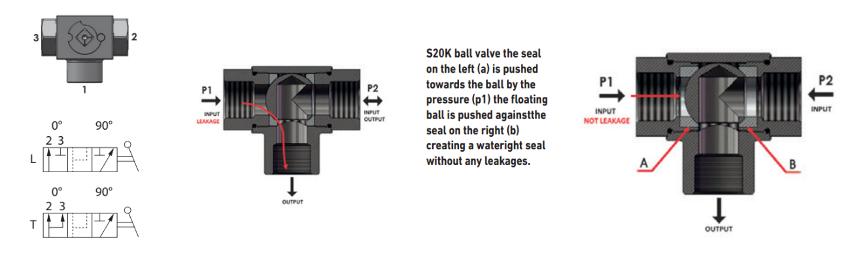

As mentioned above, there are exceptional cases where you can have one outlet and two inlet ports. In this case, it allows pressure through the side ports. This is the so-called Redfluid K series.

In the case of L-flow, the inlet pressure pushes the floating ball into the seat on the other side port. This creates a perfect leak-proof seal. The seat material must be suitable for the type of fluid and pressure of the application.

When T-flow is allowed, these valves are known as mixing valves.

At RedFluid, we have two series of 3-way ball valves. The 10 series for low pressures up to 64 bar and the 20 series for higher pressures up to 2500 bar. If you have any questions, please get in touch with our experts.

Share this post

Imagine you’re running an industrial plant and you’ve got a diaphragm seal protecting a pressure transmitter. Over time, the process fluid starts leaving deposits and

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to