Hydrogen Check Valves

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to

In today’s guide, I will discuss all essentials of selecting the correct ball valve seat materials.

Ball valves are essential in allowing to cut or pass the flow and pressure of a piping system. Moreover, they are used in industries such as the petrochemical and pharmaceutical where leakage could represent a terrible consequence for the environment or the product itself. Therefore, the ball valve seat is critical in such situations since it is responsible for sealing the fluid inside and distributing the seating stress uniformly.

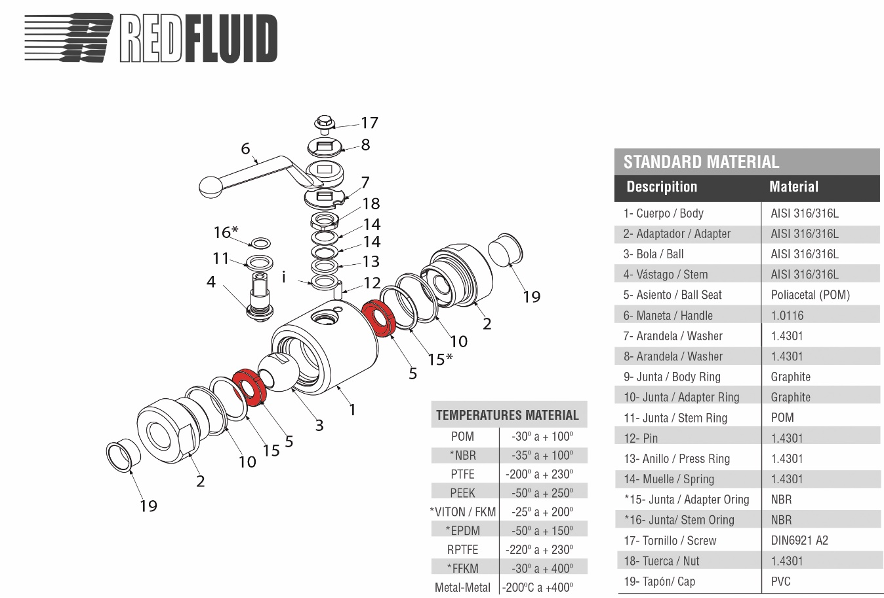

In the below picture, we have painted the valve seats in red color so you can identify where is the valve seat:

So, selecting the appropriate ball valve seat materials is vital to guarantee the performance of the valve and the safety of the product and the environment. The most common ball valve seat materials include PTFE, PEEK, and POM.

POM, called Acetal, POM-C, or Delrin, is trademarked by 3M. To select the most appropriate one, there are three main factors to consider:

Fluid compatibility refers to the material being capable of operating in contact with the fluid without having an adverse reaction.

PTFE, also known as Teflon, has very high chemical compatibility, which is why it is commonly used across different applications. Moreover, it is also produced in FDA grade, thus making it compatible with pharmaceutical, food, and drinks products. The only compatibility problem of the PTFE appears when exposed to fluorine or alkalies. We also do not recommend PTFE seats for pressures up to 350 bar.

PEEK is a material with very similar properties to those of the PTFE. Therefore, its fluid compatibility is also similar, including FDA grades. However, it may fail when exposed to sulfuric acid.

Finally, while POM fluid compatibility is extensive and includes radioactive applications, it is essential to highlight that it does not perform well with oxygen flow.

If you want to verify compatibility with the fluid of your application, you can use our compatibility tool here. Our tool allows you to select a material and will tell you how compatible it is with the specific seat.

Another critical aspect of selecting the appropriate ball valve seat materials is the range of temperatures where they can operate. Many materials react differently to temperature changes, and some lose their properties when the temperatures go above or below their normal operational ranges. If a ball valve seat loses its properties or experiences thermal deformation, the sealing power is lost, and the undesired leakage may occur.

We recommend selecting a high-temperature seat or a three-piece ball valve for Socket Weld valves. In that case, the temperature will increase and may melt the valve seats.

When it comes to PTFE, the operational temperature can be in the range of -45°C to 230°C. Now, if your application exceeds these limits, you will be better off using PEEK seats since this material can perform well within the range of -56°C to 315°C, including steam service up to 260°C. Those figures are theoretical since it needs to be added a safety factor.

POM is a more limited material when it comes to temperature. This material can only work at low temperatures within -56 °C to 100°C. However, POM would be an appropriate ball valve seat material for applications where pressure is more critical than temperature, which takes us to the next point.

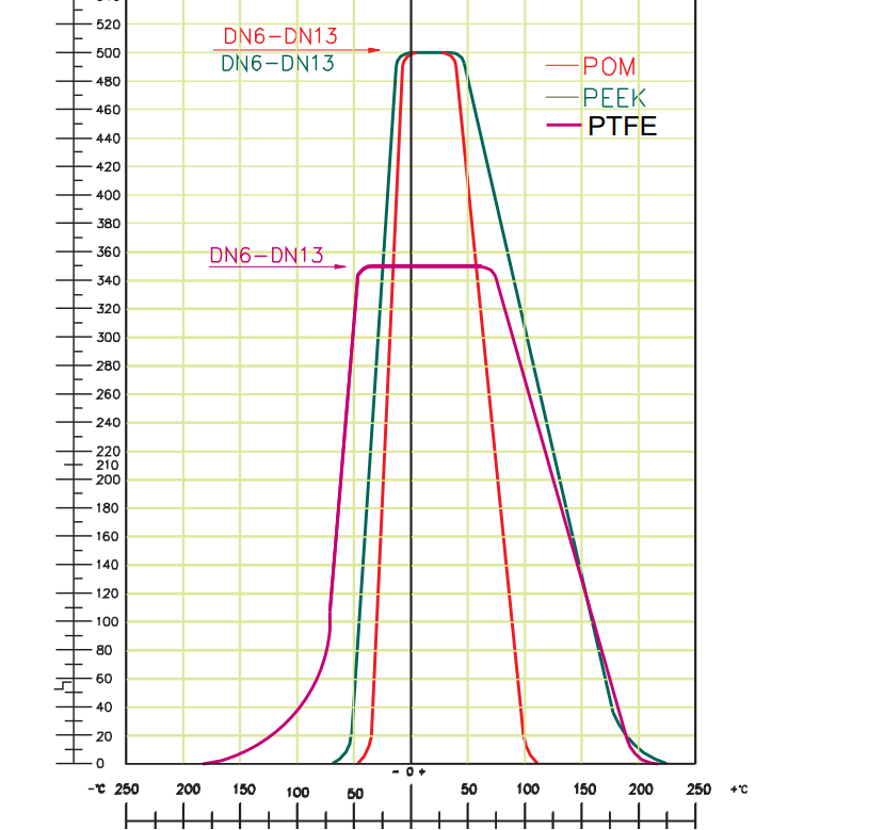

Temperature ranges with safety factors:

| POM | PTFE | PEEK |

| -30ºC | -40ºC | -50ºC |

| +100ºC | +190ºC | +250ºC |

Similar to temperature range, pressure range refers to operating pressure values where the ball valve seat material will not suffer deformation or alter its properties. While some materials may be strong enough to withstand high pressures, others may fail at certain levels.

For example, PTFE ball valve seats will have no problems operating at pressures reaching the 350 bar.

You can refer to this table for maximum pressure ranges according to the valve diameter:

| Valve Bore Size | POM | PTFE | PEEK |

| DN6 DN10 DN13 DN20 DN25 | 500 BAR OR MORE | 350 BAR | 500 BAR OR MORE |

| DN 32 – DN40 – DN50 | 450 BAR OR MORE | 175 OR 150 BAR APROX. | 450 BAR OR MORE |

As you can see, there are many different aspects to consider. PEEK may be better for some applications because they need valves operating with hot water or steam. For others, the low friction coefficient of POM may be more relevant.

So far, we have only analyzed the maximum working pressure at ambient temperature. Depending on the temperature, the valve pressure is less. But when we arrive at very high or very low temperatures, the pressure that can withstand the valve is different. In the below graph, we see a comparison of the three seats for a 1/2″ valve (DN13) working pressure and temperature chart:

Also, there are variations of these materials, like the reinforced version of the PTFE called RPTFE that, with its 15%-25% glass fiber reinforcement, provides an improved lifecycle. Another example would be the TFM, a second-generation PTFE with better stress resistance and recovery and higher pressure capability, elasticity, and resilience. We have recently added TFM as an option for some specific valves.

An Oring or gasket is an elastic ring that prevents the fluid from leaking. This elastomeric material usually is FKM or Viton, NBR or Buna, FFKM or Kalrez, EPDM, etc. The temperature of the o-ring needs to be checked as well since it can melt if the working temperature of the valve is too high.

If you have any other questions, do not doubt contact us. And if you prefer, you can call us; we love to have a little chat with you.

Share this post

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to

You’ve probably heard about high-temperature or cryogenic valves, the ones that are incredibly resistant because they operate under extreme conditions. But what makes them so

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

Esta web utiliza Google Analytics para recopilar información anónima tal como el número de visitantes del sitio, o las páginas más populares.

Dejar esta cookie activa nos permite mejorar nuestra web.

Please enable Strictly Necessary Cookies first so that we can save your preferences!

One Response