NPT Swivel Nut: How to Achieve Rotating Connections with a Tapered Thread

Imagine you’re installing a pressure gauge on a pipeline and, as you screw it in, you realize that when it finally tightens… the dial is

Type Approval is a certification process by which a classification society validates a product’s design for marine or offshore use. It involves reviewing drawings, assessing construction, and performing prototype tests to ensure the component meets applicable technical and safety requirements. In essence, the product design is examined once and, if approved, that certification is considered valid for all future products of the same design.

This approval is essential in the maritime and offshore sector for several reasons:

“Classification Societies are the organizations that issue Type Approvals.”

Type Approval certificates are issued by classification societies—organizations specialized in maritime safety and technical standards. These entities set rules and standards for ships and equipment and verify compliance. Among the main classification societies worldwide (members of IACS, the International Association of Classification Societies) are:

All of them offer Type Approval schemes with a very similar approach. The manufacturer applies for certification, and the society performs a technical design review, physical testing, and manufacturing audits before issuing the certificate. While certificates from different societies are not identical, in general a Type Approval issued by any of these organizations indicates that the product meets recognized standards. In some cases, mutual recognition agreements exist: for example, IACS member societies in the European Union share certain approvals under a common scheme, which helps avoid unnecessary duplicate testing. Nevertheless, for specific projects it’s advisable to check whether approval from a particular society is required (for instance, if an owner prefers certificates from a specific entity).

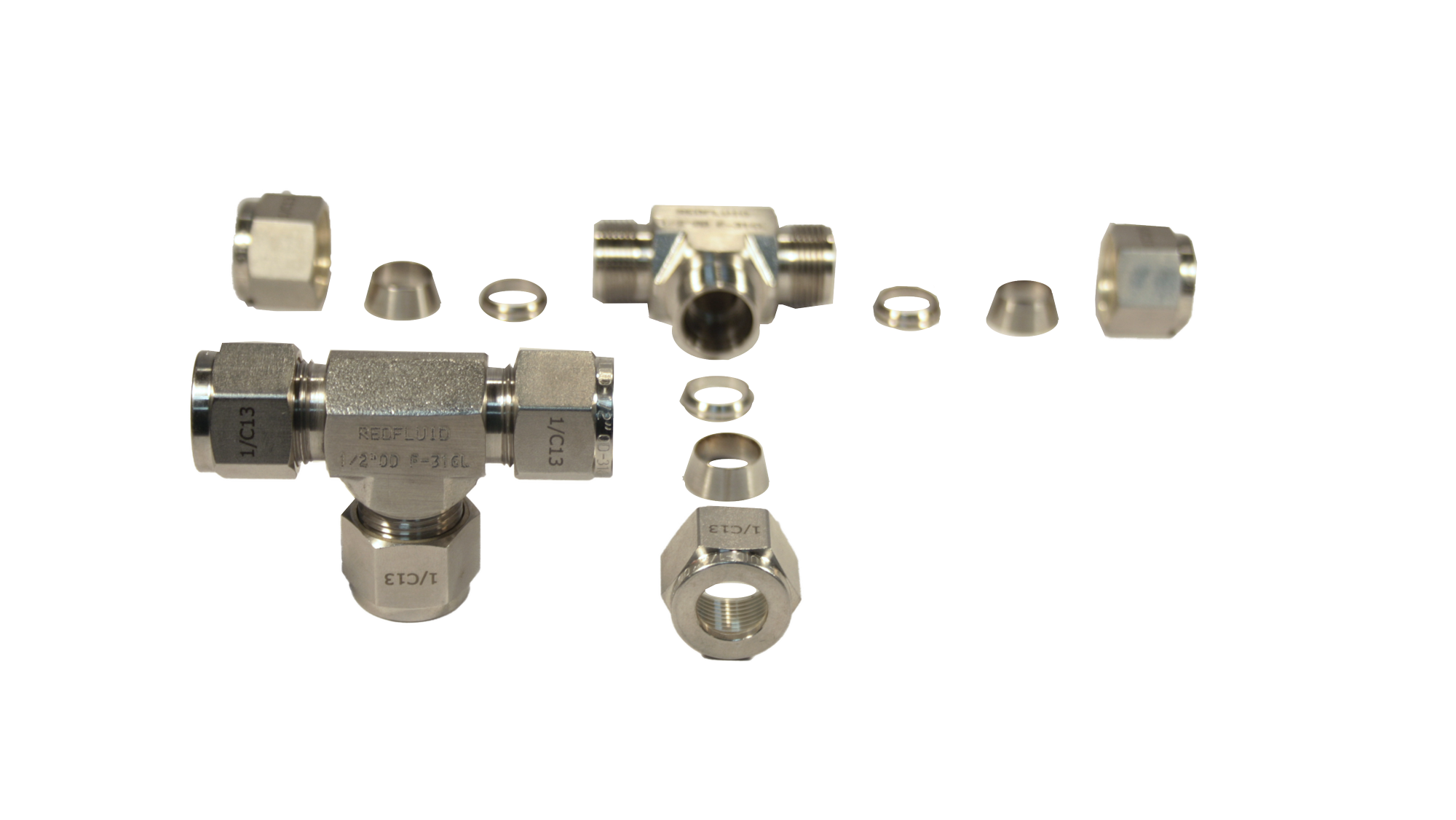

A practical case of Type Approval is Redfluid’s double-ferrule fittings used in instrumentation and hydraulic tubing. These small adapters, elbows, tees, unions, and crosses ensure leak-tight connections in high-pressure systems. Despite their size, they’re critical: a leak on a ship or platform can have serious consequences. That’s why manufacturers often seek Type Approval for their fitting lines, proving they deliver safe, consistent performance under extreme conditions.

To achieve certification, representative tests are performed on product samples, such as:

In addition, leak (tightness) tests are usually included and, where applicable, pulsating pressure or thermal shock tests, ensuring robust performance under different conditions. All these tests are witnessed by the inspector from the relevant classification society, guaranteeing the objectivity of the results.

At Redfluid we offer double-ferrule fittings with Type Approval—issued in our case by Bureau Veritas.

In simple terms, our fittings have been examined and approved for installation on different types of vessels and maritime structures, such as:

In short, with Redfluid fittings you can cover virtually any relevant type of vessel or floating platform: from steel oil tankers to private yachts, including naval vessels and offshore platforms.

The Type Approval covers our range of double-ferrule (twin-ferrule) fittings in sizes from DN3 to DN50 (approximately 1/8” to 2” in diameter). All these fittings are manufactured in AISI 316/316L stainless steel.

Thanks to this approval, these fittings are considered suitable for onboard piping systems of Classes I, II, and III, i.e., all kinds of fluid services—from the most critical (high pressure, fuels, oil, steam, etc.) to general services.

Download the full catalog here:

With the approval granted, a double-ferrule fitting is pre-certified for use on ships and platforms. In practice, this means a class inspector or surveyor will not require individual tests for that fitting when inspecting the installation, nor—in most cases—will they ask you for an EN 10204 3.2 type certificate, as long as it’s within the approved scope.

The result is a faster installation with solid documentation support. For the manufacturer, holding the certificate increases market acceptance of their products in the naval industry worldwide and demonstrates a commitment to quality. Likewise, classification societies typically require the manufacturer to have quality systems (e.g., ISO 9001) and conduct periodic plant audits to ensure production continues to meet standards and that traceability is maintained between each piece produced and the approved design.

And… if you still have any questions or need hands-on guidance for your project, get in touch and we’ll help you!

Share this post

Imagine you’re installing a pressure gauge on a pipeline and, as you screw it in, you realize that when it finally tightens… the dial is

Sounds familiar? The technician looks for a fitting, maintenance can’t find it, purchasing places an urgent order “for yesterday”… In the end, production gets delayed,