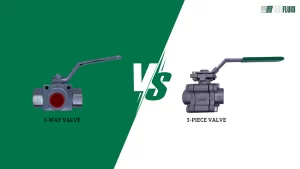

DIFFERENCES BETWEEN 3 WAY VALVES (L-PORT, T-PORT) AND 3 PIECE BALL VALVES

Do you know the difference between a 3-way valve and a 3-piece valve? There’s a lot of confusion on this topic, and many times you

When talking about high-pressure valves, several technical terms can lead to confusion and mistakes when choosing the correct pressure valve for the application in question.

But don’t worry, I’ll explain it to you in a moment.

We’ve decided to end confusion with this dictionary-style guide about pressure valves.

Stay tuned, and let’s go!

The acronym PSI refers to Pounds per Square Inch (Pound per Square Inch), the most widely used pressure measurement unit in English-speaking countries.

The most commonly used 3000 PSI is 206 bar, and 6000 PSI is 413 bars.

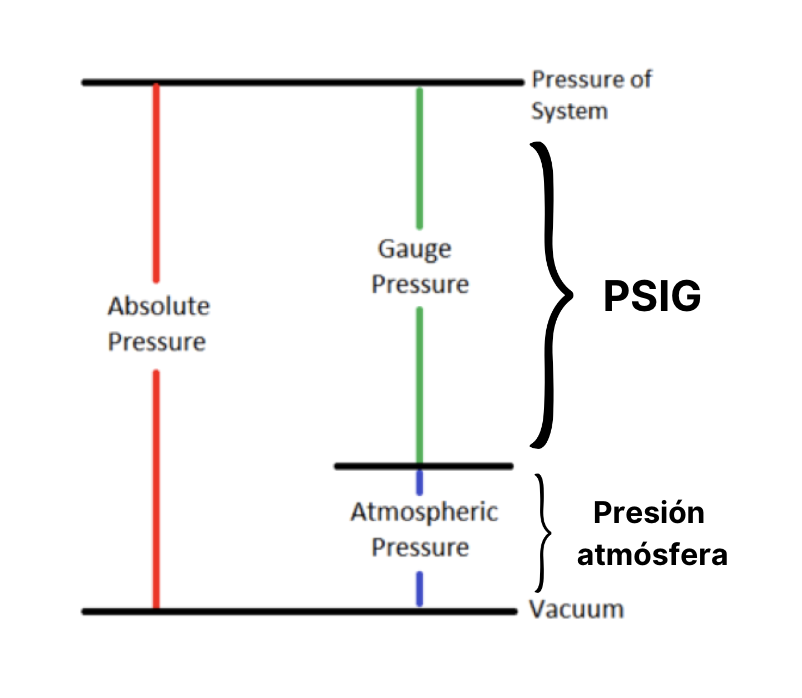

The acronym PSIG refers to Pound per Square Inch Gauge. It represents a measure of pressure relative to atmospheric pressure as read on the pressure gauge. The unit of force used is PSI.

The “G” reminds us that we are discussing this pressure difference. When we measure the tire pressure of a car or bike tire, the pressure gauge reads the difference in pressure between the air inside the tire and the air outside the tire. This is the gauge pressure and is PSIG.

The absolute air pressure at sea level is approximately 14.7 psi. Suppose the air pressure in the car tire is 30 PSIG. Then the absolute pressure inside is 30 + 14.7 = 44.7 psi. Sometimes, we write that as 44.7 psia (pounds per square inch, absolute) to remind us that we are talking about absolute pressure. In either case, we could use psi. It just helps to avoid confusion to use psig or psia as appropriate to be clear about what we are talking about.

Although in the international system (SI), the unit of pressure is the pascal (newton / square meter). In my opinion, it is the most famous unit in Europe and Spain. In the industrial world, it is also one of the most used. 1 bar is equivalent to 100,000 Pascals or 100 Kilopascals which is the same.

The equivalence between bar and psi corresponds to 1 bar = 14.5 psi.

So far, we have been talking about pressure units, but let’s complicate the subject a little more. The pressure that a valve, pipeline, or pressure equipment can withstand depends on other factors, such as the material of construction and the working temperature.

This is why we have created standards and nomenclatures to refer to equipment pressures in the industrial world.

It doesn’t sound straightforward, but it is not. It’s a matter of understanding it in a minute.

The rating refers to the total pressure the body and stem can withstand without leakage. Body static pressure requirements and pressure rating will be expressed in various ways depending on the manufacturer, standard, and type of valve.

The ANSI class is used primarily for flanged valves. It is defined as the maximum amount of pressure the flange or valve can withstand at increasing temperatures. There are seven primary pressure classes, which are 125, 150, 250, 300, 400, 600, 900, 1500, and 2500.

Many customers use LBS, LB, CL, or # interchangeably. To my understanding, they are synonyms. The old 1973 nomenclature used LBS and was, for example, 150LBS or 150lb, and as the standard evolved, the correct name was CL. You can also see it in the ANSI blog that I leave HERE.

Hey, but be careful. This is where we all go wrong:

We must be clear if we are talking about pounds and, therefore, PSI (pressure unit) or ANSI Class. Working pressure 150 PSI (10 bar) is not the same as working pressure CL 150 (20 bar).

For example, Redfluid 3000 Series needle valves are not CL3000 but are 3000 PSI (250 bar) equivalent to CL 1500.

Then we have the Nominal Pressure (PN), a type of classification that uses the operating pressure value to identify the valve, including the high-pressure valve. This is mainly used in the standard European system, including DIN, EN, BS, and ISO. This is why the valve pressure is indicated in bar. Thus, a PN250 valve works at 250 bar pressure, equivalent to 3,625 psi, and does not correspond to an ANSI class 250.

The pressure rating (PN) or class (CL) of ASME classification is used to specification the pressure of a valve. The API 6D standard is the one that tells us the equivalence between PN and Class.

Come on, let’s take a look at some data.

Table of equivalences between PN (Nominal Pressure) and Class (ASME):

| PN According to EN 1092-1 or ISO-7268 | Class according to ASME B16.34. |

| PN 20 | CL 150 |

| PN 50 | CL 300 |

| PN 64 | CL 400 |

| PN 100 | CL 600 |

| PN 150 | CL 900 |

| PN 250 | CL 1500 |

| PN 420 | CL 2500 |

Outside the API 6D standard but commercially used, we have the following classes:

| PN 140 | CL 800 |

| PN 690 | CL 4000 |

| PN 750 | CL 4500 |

In which standard are Class 800 valves listed? Class 800 is listed in API 602 and is equivalent to about 132.4 bar or 1920 psi pressure. It is an intermediate class between 600 and 900 and is usually rounded to PN140 or 2000 PSI.

Class 4000, I believe, is not in any standard, but some manufacturers and commercial catalogs use it. Class 4500 appears in ASME B16.34 but not in the flanged standard since no one will use a flanged valve at these pressures.

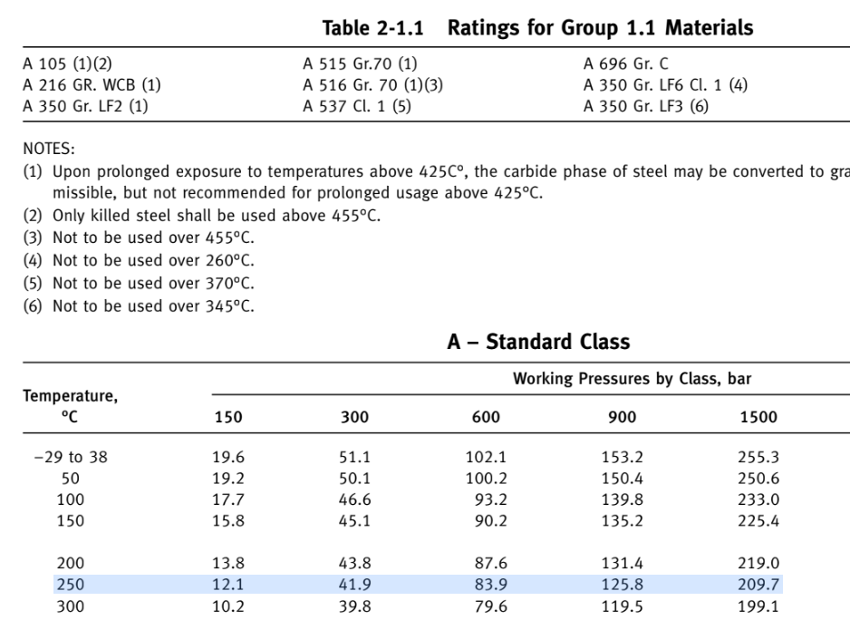

Important I will keep repeating … Do not confuse the rating number with the operating pressure value for the valve or flange connection. These ANSI classes have temperature pressure charts that correlate with the flange and/or valve ratings to determine the operating pressure at the corresponding operating temperature.

For example, a class 1500 valve in 316 stainless steel, at a temperature of 25ºC, can withstand a pressure of 248 bar, while at 250ºC, it can only withstand 166 bar. But then in Carbon Steel A105, at 25ºC, it can work up to 255 bar, and at 250ºC, only 209 bar. That is why we must enter tables of each standard and filter by temperature, pressure, and material to determine which class we are in.

We continue with more nomenclatures. We encourage you. If you have already reached this point, we are almost there.

WOG (Water, Oil, Gas) is a pressure rating for valves at ambient temperature. Gas refers to a vaporized liquid, such as steam, and does not cover combustible gases. Oil is a free-flowing liquid with a higher viscosity than water and lubricating characteristics.

, The MSS-SP-25 standard itself indicates that WO (Water, Oil pressure), WOG, GLP (Gas Liquid pressure), WWP (Working Water Pressure), and W (Water pressure) are synonyms and equivalent to CWP. CWP and WOG are the same. Sometimes it is also called CWP (Cold Working Pressure), and it is the same. The MSS SP-110 standard itself defines it as follows: CWP (Cold Working Pressure) is the maximum allowable pressure rating at normal “ambient” temperature conditions, which are generally understood to be -20°F to 100°F (-29°C to 38°C) and it is evident from the examples in the standard itself that the units are PSI.

These will be in PSI. Just as easy as that, change WOG to PSI, and you have it. For example, 600 WOG equals 600 psi at room temperature. It’s straightforward, but please don’t confuse it with class. Let’s go by note: 2000 WOG = 2000 PSI ≈ CL 800 ≈ PN 140.

This term translates as maximum allowable working pressure and is defined as the highest amount of pressure the valve is rated to operate or can operate at a specific temperature. It comes from the ASME Pressure Vessel Code and refers to the maximum working pressure. Essentially, it does NOT refer to the burst pressure (BP= brust pressure). MAWP must be equal to or greater than the design pressure. Pressure units are always indicated, e.g., MAWP 1500 PSI.

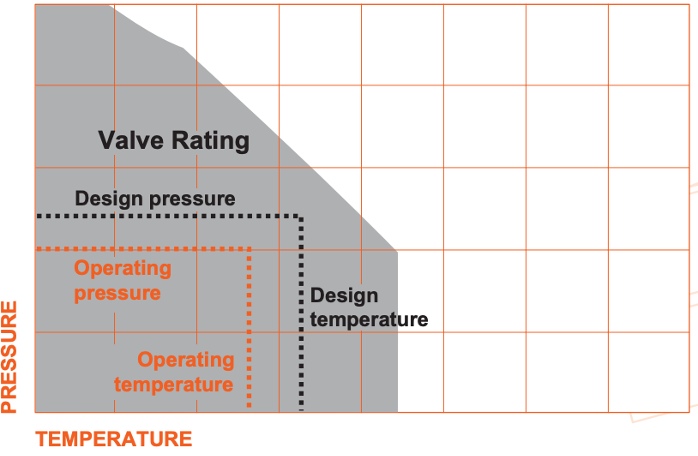

And finally, consideration of operating pressure, design pressure, and Maximum Allowable Working Pressure (MAWP).

Operating pressure: Pressure at which the equipment works normally.

Design pressure: Operating pressure + Excess pressure that the equipment may have during its operation.

MAWP: Maximum working pressure indicated by the manufacturer at which the equipment can operate.

Test pressure: Pressure at which the manufacturer tests the equipment or valve without leakage or at the agreed leakage coefficient. Usually, the test is for a short time.

Burst Pressure: Pressure at which the equipment is irreversibly damaged and commonly not tested until rupture.

Final selection: Once the valve and all its elements have been considered in terms of pressure and temperature, you must round up to the subsequent available commercial pressure or “rating” of that valve in terms of material, pressure, and temperature. Therefore, the actual “normal” operating pressure and temperature will be safely within the rating or class of the valve itself:

Buuuut let’s not fool ourselves… all this is something dense, very engineering stuff.

Since I’m the typical person who studies summaries instead of reading the whole book, I thought I’d make a cheat sheet about all these topics for my fellow bloggers.

I leave you the cheat sheet of the whole issue of pressures, so you have it at hand when you need it, you just have to enter your email here:

Of course, you can contact our team of experts if you have any questions.

Share this post

Do you know the difference between a 3-way valve and a 3-piece valve? There’s a lot of confusion on this topic, and many times you

What is a check valve with adjustable cracking pressure? If you work with check valves and are always adjusting the pressure, cracking pressure, or opening

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

Esta web utiliza Google Analytics para recopilar información anónima tal como el número de visitantes del sitio, o las páginas más populares.

Dejar esta cookie activa nos permite mejorar nuestra web.

Please enable Strictly Necessary Cookies first so that we can save your preferences!

3 Responses

Thanks for putting this together. This is super helpful for our new engineers. I think there is one typo in the caption under the picture showing Table 2-1.1. I think that is from B16.34, not B16.35. I don’t think B16.35 exists.

MANY THANKS TO YOU

This article is help full

MANY THANKS TO YOU