ELECTRICALLY ACTUATED NEEDLE VALVE

Many times, clients ask me, “Hey Kike, do you have a valve that can replace globe or control valves?” Of course, we do!But can a

How easy it would have been if I had made this dictionary about actuators much earlier, or if someone had done it for me! What a lot of questions and time we all would have saved.

But it always happens. When they ask you for product specifications, you start drenching them with endless technicalities.

It doesn’t seem like it, but even talking about actuators, there are a thousand words you have to know, and if you don’t remember them… you don’t know half of them.

Are you a valve or actuator professional? Do you need a guide to follow the thread of any valve automation conversation?

Well, stay and read on.

I leave you with this dictionary about actuators in case you can’t remember what any word that has to do with actuators and valves means, so you have a handy reference.

Let’s get down to business.

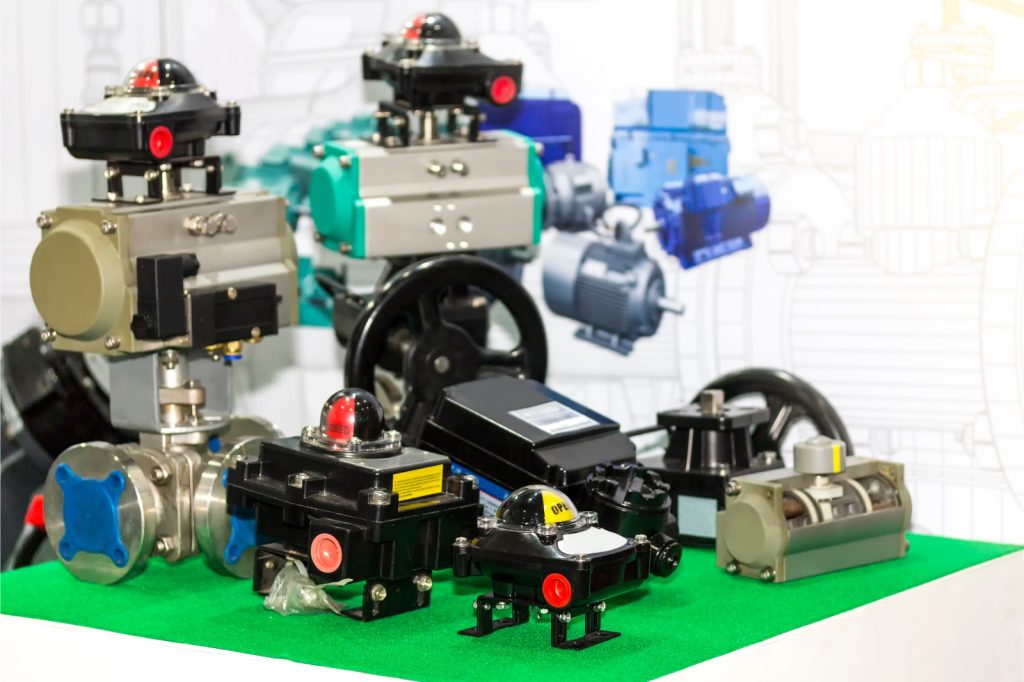

Actuators

In this case, we have many types:

AC/DC

AC stands for alternating current. DC stands for direct current.

ATEX

Set of European regulations for explosive atmospheres. That is to say; if the fluid or the environment in which the valve circulates or is installed can explode, you must order the valve, actuator, Namur, limit switch, etc., always all 100% Atex.

Block (safety)

In case of power failure, it is nothing more and nothing less than a battery to maneuver the valve in case of emergency.

Connectors

An accessory that many forget to install, and it is just then that problems arise when connecting the power cables. They can be bipolar or tripolar.

Cylinders

Used for valve actuation. There are many types:

Connecting Die

Die that stays between the valve shaft and the actuator in a pneumatic ON-OFF valve. It is the connection between the valve shaft and the actuator.

DA

Double Acting Actuator

Electrovalve or solenoid valve

It is any valve that needs a magnetic field to operate. They can be of several types: two-way, 3-way, or 4- and 5-way.

EN ISO 5211

It is the dimensional pattern with which the holes or anchorages of the valve are made to fit an actuator.

Emergency manual override

Accessory used in case of electrical failure to operate the valve manually.

Exhaust silencer

When the valve exhausts, the exhaust silencer reduces the noise.

Gland (cabled)

The part that holds the inlet cables to the box.

Ip66 or ip67

The standard tells us the degree of water tightness that the actuator has, whether it can get wet or be outdoors or not.

Limit switch

It is a gadget that can be ordered as an accessory to an actuator. Usually, it can have two missions: stopping the actuator when the valve has reached its position and sending a signal to a PLC to indicate its actual position.

LED indicator

It is an accessory used to check the operation of the motor. The LED lights up when the engine is running, which is nothing more than a small light.

Multi-turn Motor

The actuator usually has these elements: position indicator, limit switches, and torque limiter.

Mast

Maximum Allowable Stem Torque to which a quarter-turn valve stem can be subjected during operation without mechanical failure or if I want to understand it easily: it is the limit of force (torque) that I can apply to the valve without loading it.

M12 plug

M12 connector, A-coded, is a cable that you do not have to terminal all the wires to connect the final sensor box. A marvel to buy a finished solution in the plant. The alternative is to screw the terminals.

NAMUR

It is the name of the connection that is used between an actuator and a solenoid valve or pneumatic control valve that is the one that tells you when the air enters or leaves the pneumatic actuator. There are 2, 3, and 4-way all around the world.

Normally open

It is when in case of failure, we want the valve to be open.

Normally closed

It is when in case of failure we want the valve is closed.

O-rings

These are elastomers to prevent leakage between two joints.

Opening limiter

To regulate the flow so that the valve does not open 100%.

Position indicator

An accessory that indicates in which position the valve is located. The position indicator can be mechanical, inductive, or capacitive.

Positioner

Converts the valve and actuator into a control valve.

Pneumatic (Positioner)

An accessory that converts an ON-OFF valve into a control valve.

PNP

In the actuator world, it usually refers to the type of connection on the inductive limit switch box sensors. If PNP = Switched Positive and if NPN = Switched Negative.

Regulator (exhaust)

These filters are inserted so that the valve does not make noise and also removes impurities from the outside.

Solenoid (or coil)

Primary mission: to generate the magnetic field. Mainly to be able to use the solenoid valve.

Spring-Return (SR)

Spring-acting actuator

Torque

It is the force in Nm (Newtons Meter) that we have to do on a valve so that it can open. If a lot of power is required, i.e., the valve is very hard, a larger actuator is needed. The torque will also be more significant if the valve works at high pressure.

Torque limiter

Accessory that works by stopping the motor due to the torque increase when the valve reaches its position.

Threaded BSP

Cylindrical thread.

Threaded NPT

Conical thread, you can see our article about the differences between NPT and BSP here.

Threaded holes

To fix it to the actuator. Examples: Limit switch boxes and positioners. Typically follow a dimensional standard called ISO 5211.

Turret or Mounting Bracket

It is the part between the valve and the actuator. It serves to connect both and that everything fits well.

Valves

Anything you see missing in this ABC summary, write it in the comments; we read you!

And if you need any of the parts explained, don’t hesitate to contact us here or give us a call. We are always happy to talk for a bit and answer any questions you may have.

Share this post

Many times, clients ask me, “Hey Kike, do you have a valve that can replace globe or control valves?” Of course, we do!But can a

3 Responses

Great guide on actuators! Your detailed explanations and tips make it easier to understand their applications. Thanks for sharing this valuable resource!

Great to hear Tarhib. At Redfluid, we believe actuators are gamechangers and that is why we love to actuate our valves.