Flexible hoses for defense: not just any hose will do

In defense, there’s no room for error. We’re not talking about just another hose from the catalog. We’re talking about flexible hoses assemblies that must

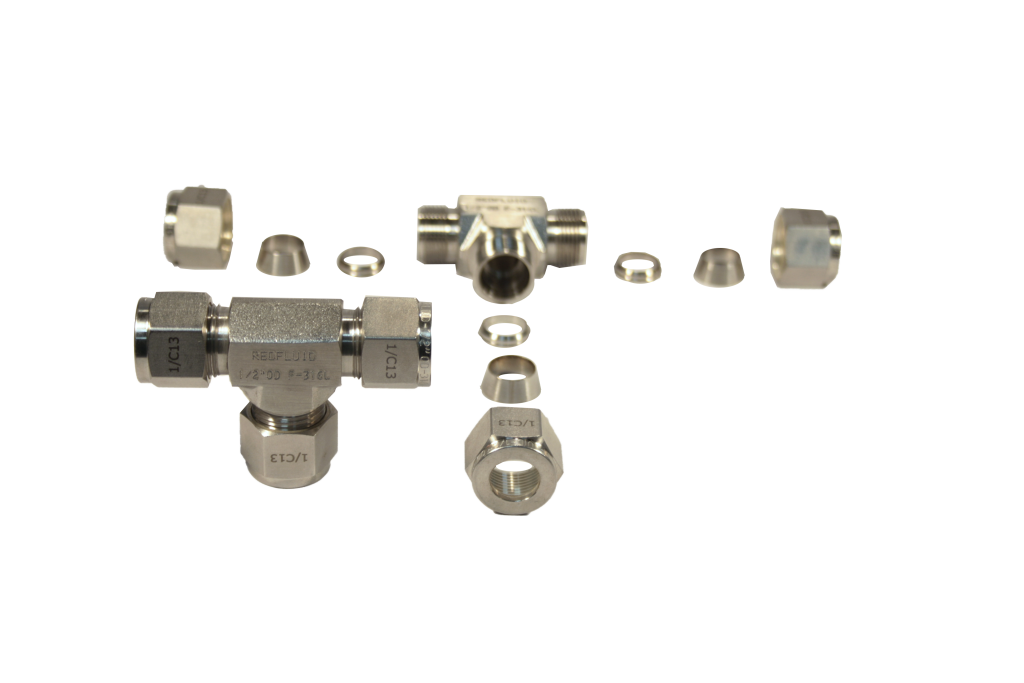

There are many who, when comparing a double ring fitting or a “Lok” type, only look at the price. BIG MISTAKE! Don’t be fooled by a small difference. What should you consider when switching to a different manufacturer of double ferrule compression fittings?

I’ll never tire of saying it. In this case, quality takes precedence over cost. There’s a lot of junk fittings circulating around the world. In the Redfluid laboratory, we like to pressure test the fittings. We’ve seen everything from fittings that fail quickly under pressure, to fittings that leak with gases, to poorly marked fittings, with threads that don’t match, etc.

I’m sharing a video of a fitting from our brand, where you can see that the fitting withstands all the pressure and what ends up bursting is the tube. In other words: our fittings are top-notch.

Crucial. The fittings must be “interchange” and “intermix“. Let’s see what we’re talking about:

The advantage of a fitting being interchangeable and intermixable with components from other brands is that it offers significant benefits. Above all, and most significantly, a reduction in costs. It also provides greater operational flexibility and agility to quickly adapt your installations to stock availability. That is, if a famous and international brand tells you it will take 22 weeks to supply a fitting, and another local brand (ahem… Redfluid) says it will take less than 2 weeks and, moreover, is cheaper, it might be worth making the switch.

And just to make it clear, at Redfluid ALL our fittings are Interchange and Intermix. No doubt about it.

An ideal key partner should have the capability to manufacture short runs of more or less customized fittings. Plus, they need to have short delivery times, for both standard materials and more exotic ones. But… without taking advantage. We’ll help you out, but if you only ask for the tough stuff and just one unit, well, that’s not really what we’re here for… There will always come a time when you need a reduced central T, a BW Elbow Side connection, or some other rarity. Or perhaps an exotic material like duplex, super duplex, Inconel, Hastelloy… And if your manufacturer or distributor doesn’t have the flexibility to supply it, you’re back in trouble. Moreover, they should be able to manufacture fittings with ends for tubing BW, SW, BSPT, BSPP, NPT, UNF, and even cone & thread.

Pay close attention! Whenever you use special gases like hydrogen, you must inform your fittings manufacturer. Our double ring fittings are compatible with hydrogen and other special materials. If you’re looking for a supplier, look for one that offers to withstand high hydrogen pressures as a standard feature. And not just because hydrogen might be the fuel of the future, but also to ensure that the fitting is completely leak-free.

If you’re interested in the world of hydrogen, I’m sharing a catalog that showcases all the products we have that are compatible with hydrogen.

In the video below we see a test of a brake line breakage in this case with hydraulic oil. If you compare it with the video above, the breakage is much less aggressive, that’s why the brakes must be Hydrogen ready if at all.

I might sound a bit repetitive. Buuuuut… this is also extremely important. When you’re looking for tubing for your fittings, try to get it from the same supplier. Mainly because this way, you ensure the tube works perfectly with the fittings. And since I like to make life easier, here’s an article on how to select tubing for your Lok-type fittings. You can read the article HERE.

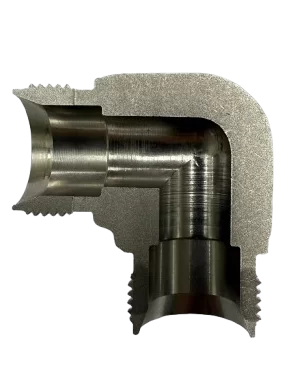

Thanks to the meticulous work of interior rounding, we ensure that every movement of fluid through our fittings is not only smooth but flawless. This precision in the finish not only optimizes flow but also significantly reduces the risk of turbulence and wear, thus ensuring prolonged and efficient operability.

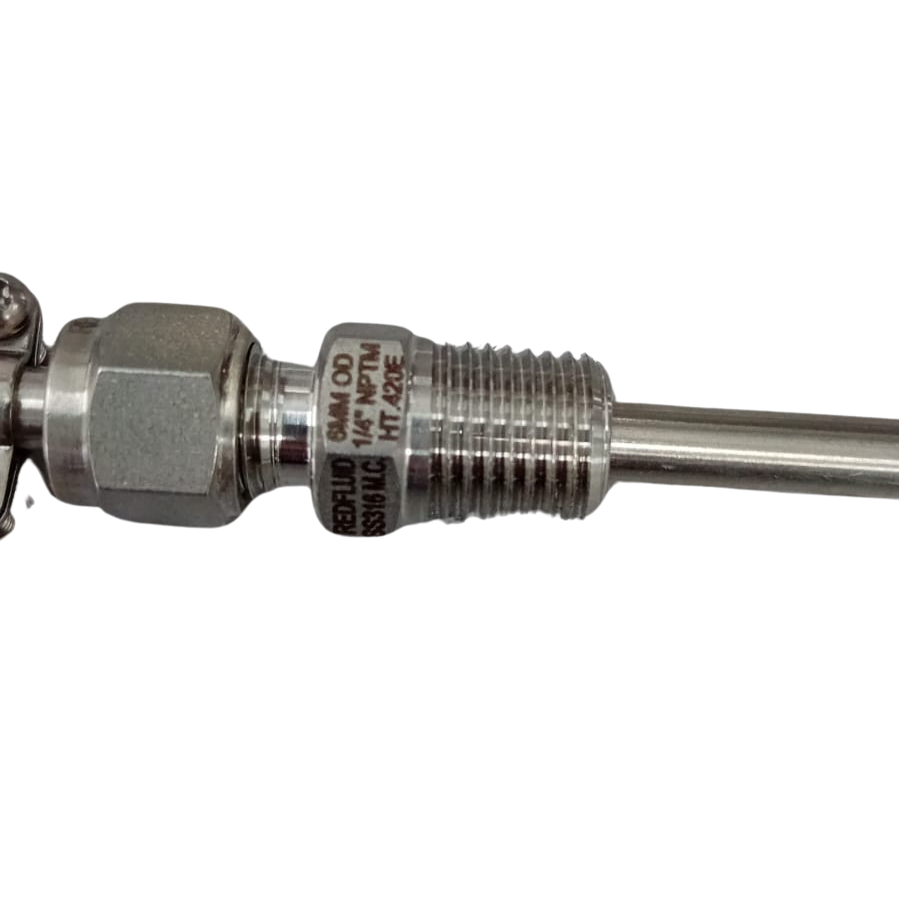

Through or sliding fittings, whose name comes from their ability to allow tubing to pass completely through them (“through”) and the ease with which they can slide over the tube for installation or adjustment (“sliding”), are a variation of double ring fittings.

This design significantly simplifies installation when the height of the tubing needs to be adjusted. It’s especially useful in the placement of temperature probes.

It’s an added option that can be requested for most fittings, as long as the geometry allows it.

Fittings must be designed and tested to ensure exceptional seal integrity in vacuum applications where any leak or poor machining can compromise the system’s integrity. Even if you don’t work in vacuum conditions, this can give you an idea of the high level of seal tightness of our fittings.

Redfluid’s oxygen degreasing option ensures that the fittings are completely safe for use in high-purity and critical environments, such as oxygen systems, guaranteeing a cleanliness of all fitting components free from grease and impurities. In this case, they are served in sealed plastic bags to prevent each piece from getting dirty.

With traceability, each fitting carries with it a history that allows us to find the quality certificate of the raw material used in its manufacture. This attention to detail is what enables the issuance of a 3.1 certificate with all the chemical and mechanical details of the raw material of the fitting body. If you want more information about 3.1 certificates, we explain it here: https://redfluid.es/en/certificates-for-valves-pipelines/

Having good technical support also helps in ordering the fittings you need. Ultimately, it adds value. Moreover, if you come with references (such as Swagelok or Parker), our technical team will provide you with our cross reference®.

We will advise you on the best selection of products, threads, connections, standards, and materials among others for your specific applications.

In the end, the most important thing is that you have the double ferrule fittings that best suit your installation. And for that, get in touch with us. After all, we know what we’re talking about.

Share this post

In defense, there’s no room for error. We’re not talking about just another hose from the catalog. We’re talking about flexible hoses assemblies that must

What is SW OD , and why should I care? What is SW OD? Can instrumentation tubing be welded and replace double ferrule compression fittings?

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

Esta web utiliza Google Analytics para recopilar información anónima tal como el número de visitantes del sitio, o las páginas más populares.

Dejar esta cookie activa nos permite mejorar nuestra web.

Please enable Strictly Necessary Cookies first so that we can save your preferences!