NPT Swivel Nut: How to Achieve Rotating Connections with a Tapered Thread

Imagine you’re installing a pressure gauge on a pipeline and, as you screw it in, you realize that when it finally tightens… the dial is

Before explaining to you How to select tubes for compression fittings…

It has happened to me thousands of times that customers, engineers or fitters select double ring fittings (Lok or Swagelok type), but then screw up the tubing. It is important to note that these recommendations can be applied to double ring and single ring DIN 2353 fittings with a single ring.

Step by step:

The first precept of the Tube Buyer’s Law is considered to be the most important of all:

“You will only buy tubing at Redfluid.”

Jokes apart:

The tubing shall be seamless only. Don’t be fooled into selecting welded tubing. It may be cheaper, but they always give problems. The welding tolerance is a leakage point for the rings of the fittings.

Let’s see, the first thing you need to know is the outside diameter x the thickness. If you already know that, you have the road won.

This nomenclature applies to instrumentation tubing and not PIPE. Pipe + SCH Schedule has nothing to do with each other!!! For more information on this see the article: difference between pipe and tube.

Go on, we continue. As an example:

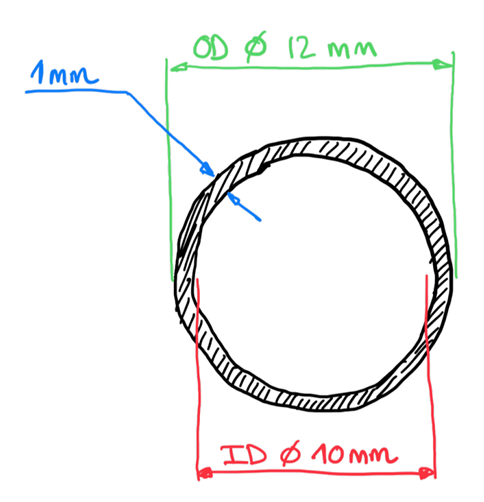

12×1 = This would mean Outside diameter 12 mm, thickness 1 mm. Another slang we see a lot is outside diameter x inside diameter. This same example would be 12 x 10:

Very easy, I use the following formula:

OD – 2 x Wall Thickness = ID

In our example 12 – 2x(1) = 10; everything fits.

Where can there be some confusion? Well, when the tube is measured in inches instead of mm. As you know 1/2 inch is 12.7 mm.

Here’s a trick: Saint Google comes to save you. When you look it up on Google, very important: the acronym of inches is in.

You type in Google: 1/2 in to mm and… MAGIC, it tells you that it is 12.7mm.

But be very careful. It is very typical to find the following nomenclature:

1/2″ OD x 0,048

How do you understand this? Easy peasy. They are telling us in inches.

1/2″ in = 12.7 mm

0.048 in = 1.24 mm

Therefore, it is the same to say = 1/2″ OD x Wall Thickness 0.048″ = 12.7×1.24 mm.

Another example:

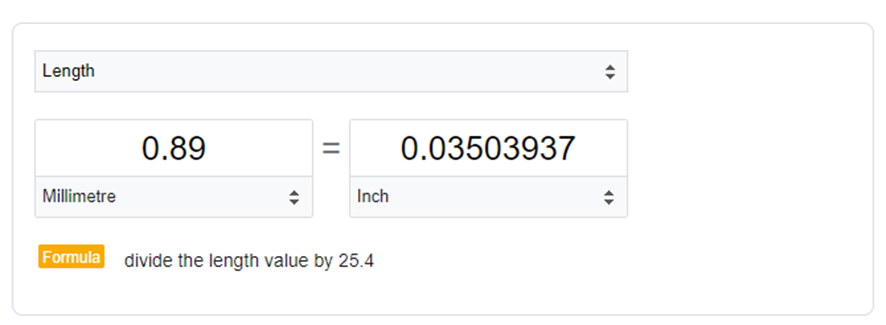

6.35 x 0.89 mm. In this case they are telling us in millimeters, and we can convert it to inches.

6.35 mm to in = 0.25 = 1/4″

0.89 mm = 0.035”

That means = 6.35 OD x 0,89 mm == 1/4″ OD x 0.035”

Table by way of summary, these measurements are normally in stock:

| Measure in mm (OD x Wall Thickness) | Measure in inches (OD x Wall Thickness) | Pressure ASME B31.3 a room temperatura in 316/L |

| 6 x 1 | 470 bar | |

| 8 x 1 | 340 bar | |

| 10 x 1 | 267 bar | |

| 12 x 1 | 220 bar | |

| 12 x 1,5 | 340 bar | |

| 12 x 2 | 470 bar | |

| 6.35 x 0.89 | 1/4″ x 0.035” | 386 bar |

| 9.52 x 0.89 | 3/8” x 0.035” | 248 bar |

| 12.7 x 1.24 | 1/2” x 0.049” | 260 bar |

The tube has to be made of the same material as the fitting, in order to avoid galvanic corrosion. The most common are fittings in 316. Therefore, the tube also has to be in 316 or 316L, indistinctly. Do not worry too much about the L.

Now that we know a little more about the material, outside diameter and thickness, we have to select the pipe based on the design pressure of the system.

There are several famous standards for pressure calculation:

It is tough, but the same pipe, with the same outside diameter and wall thickness, can withstand different pressures depending on the standard: For example, 12×1 pipe.

According to ASME B31.3 it withstands 220 bar at room temperature but surpriseee according to EN13480 it withstands 243 bar.

On our website we have a calculator that can be used to size the thickness of a pipe according to the pressure. But, if you need to know exactly or certified according to a specific code or standard, you have to ask for it to an engineering company. I leave you the link so that you can access the pressure calculator: https://redfluid.es/en/landing-pressure-calculator/

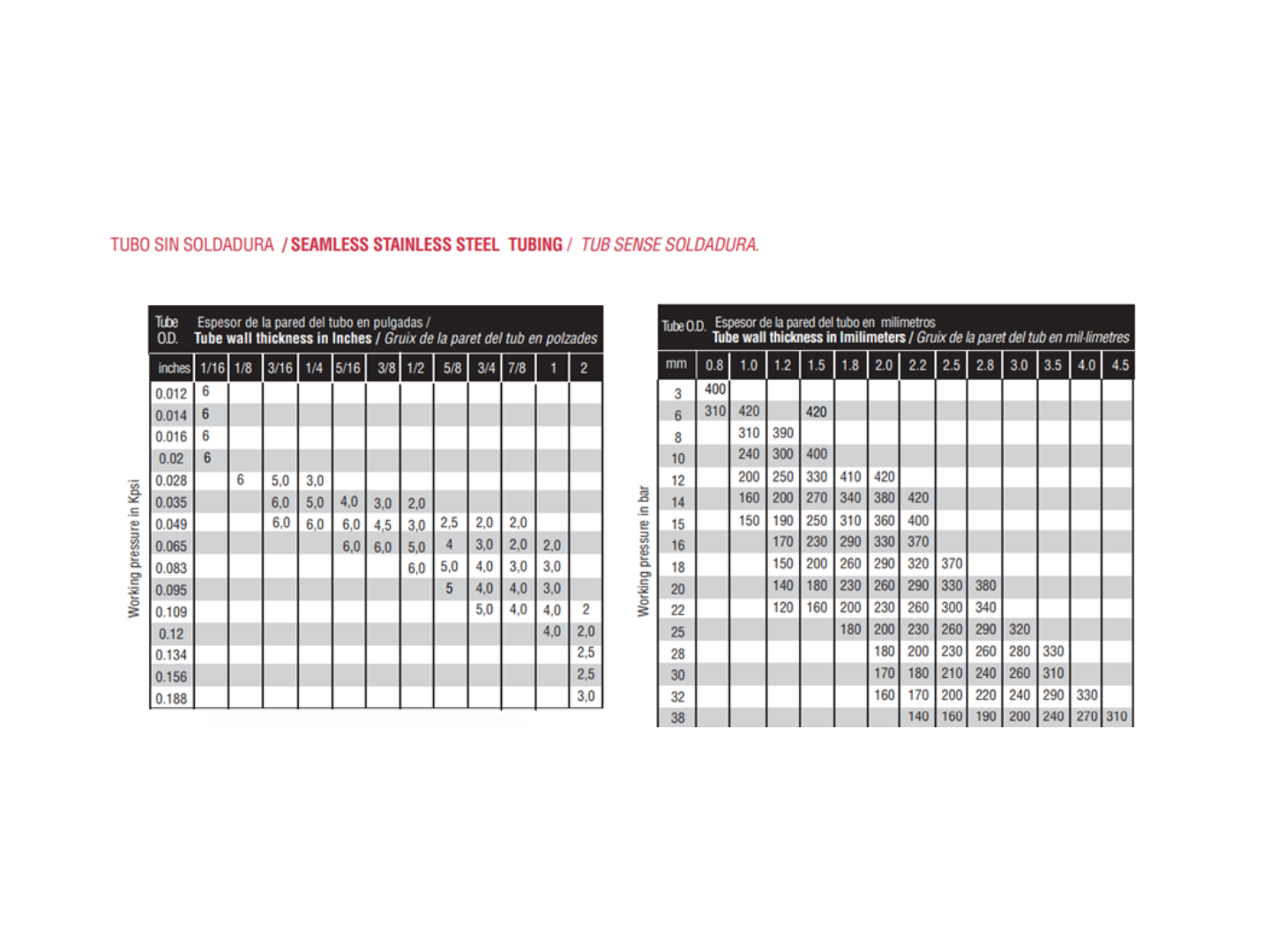

Also in the Redfluid double ring couplings catalog there is a table showing the pressure that the tubes can withstand depending on their outer diameter and thickness:

Very important: Depending on the temperature, the pressure that the tube can withstand varies.

It is important to mention that the pressure is a function of thickness, but also of tolerances, material and temperature, among others.

We also have tubing in other materials such as duplex, superduplex, Inconel, Hastelloy, 904, 904L, Titanium, Alloy 600, Alloy 625, 254SMO, 6MO, C276, 321 and other alloys.

The tube, matt or shiny?

“Since Paleolithic times”, the shiny tube has always been associated with instrumentation and the matte tube with processes. Normally the shiny one is because it is Cold Drawn, but if it were matte with all the characteristics and hardness that we require, we would consider it as good. It is necessary to check that it is Cold Drawn and that the hardness of the tube is not higher than 85 HRB.

In Europe we use ISO EN 1127: Stainless steel tubes. Dimensions, tolerances and conventional masses per unit length. In this standard we normally select the tolerance D4/T3 for instrumentation tubing. This means:

D4 = Outside Diameter +/- 0.5% minimum +/- 0.1 mm

T3 = Wall Thickness +/- 10% minimum +/- 0.2 mm

Normally the tubing is manufactured to one of these standards, any of which we have seen in installations and they generally work just as well:

There is another type of pipe that is sometimes confused, as the outside diameters are very similar. Many people call it “autoclave” type. These are pipes that can withstand up to 4000 bar (60000 psi). Normally they are used for high pressure hydrogen lines, laboratories or waterjetting. In these cases it is pipe with special treatments and with a very high thickness.

And in order not to create disappointments, we have this tube that goes together with the connection fittings type “cone and thread”. You can see it in the catalog of very high pressure accessories: https://redfluid.es/p/racores-y-valvulas-de-muy-alta-presion/

Let’s get to la creme de la creme.

Very important and elementary, dear Watson. If it is for HYDROGEN at high pressure, you have to indicate it. You need to know the chemical composition such as, for example, nickel levels, among others.

Hey, and if the world of hydrogen interests you a lot, you have to download our hydrogen catalog by clicking HERE.

Generally for day-to-day applications it is not required to degrease the tubing.

But… be careful Antonio.

If the tubing is installed in vacuum, hydrogen, flammable gas or oxygen circuits, it is much better to ensure that the tubing comes clean and free of grease. We will achieve a much better performance of the installation. For this reason, you can also request degreased tubing. We prepare it for you, as they say in Catalan, in a “tres i no res”. We do it according to our approved procedure following ASTM G93.

To summarize:

Then when you ask for the certificate 3.1 as a summary (link to certificate 3.1) you must check that it appears, quality and grade of material (316), construction standard, tolerance, outside and inside diameter, hardness and, if possible, that it is cold drawn.

Heeeeey, and if you have any other questions or need the right tubing, give us a shout HERE and we’ll get in touch ASAP.

Share this post

Imagine you’re installing a pressure gauge on a pipeline and, as you screw it in, you realize that when it finally tightens… the dial is

Sounds familiar? The technician looks for a fitting, maintenance can’t find it, purchasing places an urgent order “for yesterday”… In the end, production gets delayed,