Flushing Ring: the key to cleaning and calibration without disassembly

Imagine you’re running an industrial plant and you’ve got a diaphragm seal protecting a pressure transmitter. Over time, the process fluid starts leaving deposits and

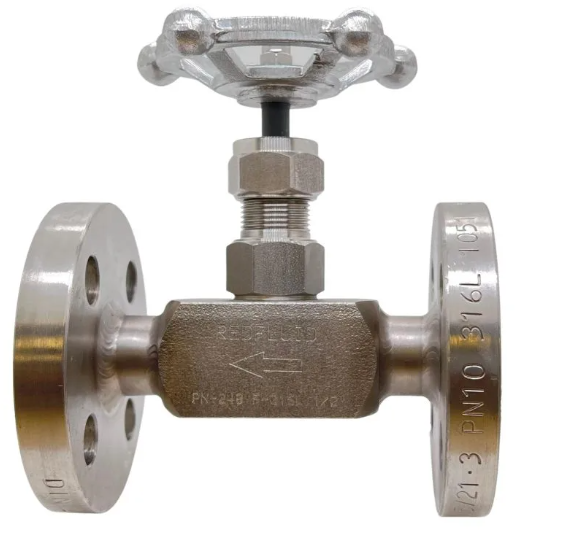

All the Essentials for Engineers and Procurement Teams to Specify and Purchase Flanged Needle Valves Correctly.

You’ve probably heard about flanged needle valves, those that can compete with control, globe, or gate valves. But why are they so useful, and what makes them special? Stick around, and I’ll explain.

First, here’s a quick video (3 minutes) where I explain how these valves work and why they might be the solution you’re looking for:

These valves stand out for their ability to precisely control flow, even under high pressures, high temperatures, or cryogenic conditions. They are an excellent alternative to control, globe, or flanged gate valves, and they also offer:

Typically, a needle valve has threaded or welded connections, but at Redfluid, we can provide the flanged connection version.

First, you need to define the flange standard you require, which logically must align with your process. As a general rule, there are two standards:

Important: if it’s ASME, we refer to Class or Rating, such as CL150 or 150#, to indicate the pressure range the flanges can withstand. On the other hand, if we use the European standard, we talk about PN or Nominal Pressure—for instance, PN16-PN40 is the most common.

If you’re feeling lost in the world of flanges, check out this blog where we reveal all the secrets to understanding the different types of flanges on the market.

Another aspect to consider when ordering flanges is whether they are Flat Face (FF), Raised Face (RF), or with a Ring Type Joint (RTJ) seal.

ASME flanges offer the widest range of configurations, as they can be ordered with RF, FF, or RTJ finishes. It’s important to note that the most common finish in the ASME standard is RF (raised face).

On the other hand, flanges under the EN standard are generally flat or Flat Face (FF). These flanges can come in Form A or B1. Form A is the most common, indicating FF (flat face) or flat surface. However, these flanges can also come in Form B1, which indicates an RF (raised face) finish.

Something fundamental to keep in mind is that when connecting a needle valve with a flange, the system’s maximum pressure will be limited by the most restrictive component.

“And what does that mean?” you might be wondering:

Basically, if the flange can handle less pressure than the valve, that will be the maximum pressure the system can withstand.

For example: a s3000 needle valve (248 bar) connected to flanges rated at PN 10. The pressure the valve + flange system can handle will be 10 bar.

This is why it’s always important to check the specifications of all components to ensure safe operation.

Remember, depending on the standard, we refer to this as Class or PN. If you have a pressure in bar and need to know its equivalent in Class, CL, Rating, or LBS, you can learn all about it in this article.

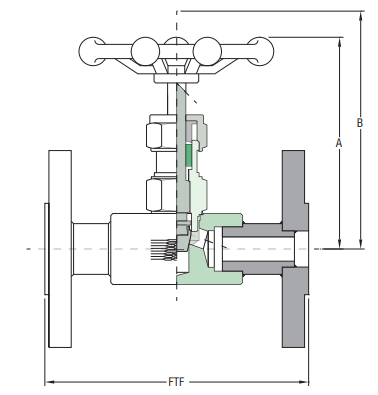

A key detail when installing flanged valves is the distance between the faces of the flanges, known as the Face-to-Face dimension in English.

At Redfluid, we manufacture it according to our catalog. If you want full access and to view the different dimensions we offer, click here:

It can also be manufactured according to the ASME B16.10 standard, ensuring compatibility with most existing systems.

Buuut if it still doesn’t fit your system and you need custom dimensions, no problem! At Redfluid, we’ll make it tailored to your requirements.

And now that we’ve come this far, it’s time to add the finishing touch: deciding whether the valve packing will be graphite or PTFE.

On one hand, graphite, due to its properties, performs exceptionally well when your system needs to operate at high temperatures and with steam. So, if you’re working with thermal processes or steam, oil, or gas systems under high pressure and temperature, graphite is your best ally.

On the other hand, we have PTFE or Teflon. Known for its excellent chemical resistance and compatibility with almost all fluids, it’s ideal for the food industry, chemical, and pharmaceutical industries, or systems requiring a clean, particle-free seal. It’s perfect for gases at room temperature.

If you have any questions or need a specific solution, don’t hesitate to reach out! And remember, for any inquiries about valves, fittings, or high-pressure systems, feel free to contact us! We’re here to help you find the perfect solution for your system.

Share this post

Imagine you’re running an industrial plant and you’ve got a diaphragm seal protecting a pressure transmitter. Over time, the process fluid starts leaving deposits and

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to