Hydrogen Check Valves

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to

But, before getting into the world of hydrogen valves, it is necessary to go step by step. Let’s not put the cart before the horse. So, let me explain what a ball valve is and why hydrogen.

First of all, here’s a video where I explain everything about this topic:

A ball valve is a device used in piping systems to regulate the flow of fluids, such as water, gas or oil. Its design consists primarily of a perforated ball that acts as a plug, mounted inside a valve body. The ball has an orifice that can be aligned with the ends of the valve to allow fluid flow or misaligned to block it.

Ball valves are appreciated for their ease of use, durability and ability to withstand high pressures. These valves are commonly found in plumbing systems, chemical industries, oil and gas processing plants, among others.

Redfluid has two large families of ball valves, the 10 Series (S10) up to 64 bar and the S20 which includes all high pressure valves from PN140, PN350, PN500 up to 1380 bar.

And be careful, the ball valve is NOT the same as a needle valve. Although they may look a little similar. I leave you the article on this subject HERE so that there is no confusion.

In ball valves we mainly differentiate between:

And, if we talk about materials, the most typical in the world of valves are Stainless Steel and Carbon Steel. But at Redfluid we also have valves in Super Duplex (in stock hehe), in duplex, in Alloy, in brass, in Monel, among others.

At Redfluid, we have the firm belief that hydrogen will solve many problems we have today.

Hydrogen has emerged as a promising candidate to lead the energy revolution and is postulated as the fuel of the future for several key reasons. Its ability to be produced from renewable sources positions it as a sustainable energy carrier, contributing to the reduction of greenhouse gas emissions. Through electrolysis, green hydrogen is obtained by using renewable electricity to split water molecules, thus generating a clean, carbon-free fuel. In addition, hydrogen stands out for its versatility, as it can be used in a wide range of applications, from transportation to stationary power generation, providing flexibility in the transition to a more sustainable future.

I don’t want to get too long, otherwise we don’t continue reading the article. In any case, if you are interested in the world of hydrogen, the other day we had an interview in FESTO. I leave it below:

But let’s get down to business:

“Can I take my conventional valve for hydrogen applications?” Well, NO. I think that’s pretty clear. And if you want to know why, just read an article I wrote a while back by clicking HERE.

You have to be very careful when ordering valves when you have a special type of fluid or gas. Not all valves or fittings are compatible with all fluids. Do not fall into the trap of buying the first one you are offered. Here is a summary of our hydrogen ball valves offer:

At Redfluid, we have different types of hydrogen ball valves depending on the pressure you need. I’ll explain them one by one and, this way, you can make a small sketch.

Yes, just as you read. One of our Redfluid hydrogen valves is in STOCK. It is important that delivery times are as short as possible.

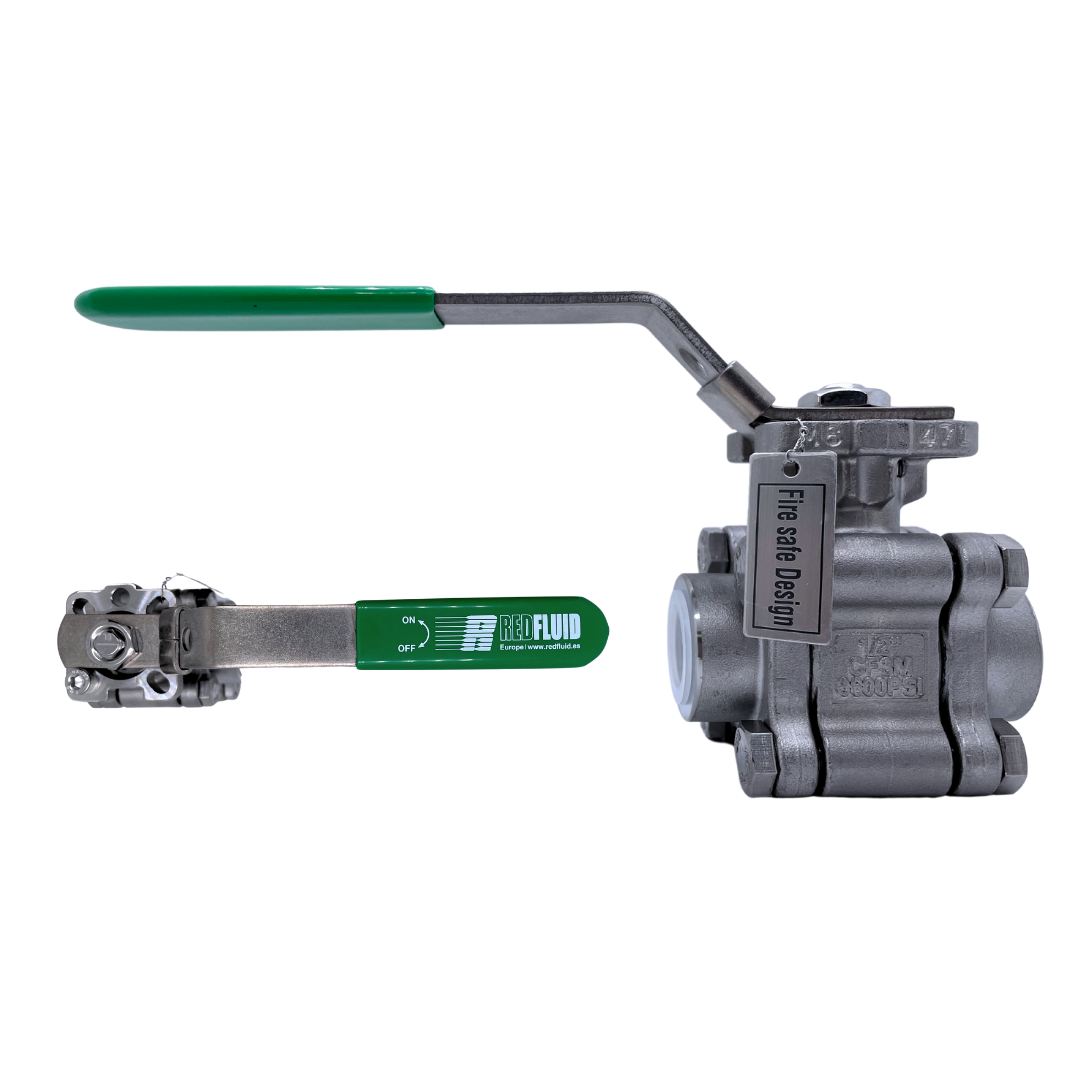

A 3-piece hydrogen ball valve is essential to ensure safety and efficiency in industrial systems using hydrogen. Their modular three-piece design facilitates maintenance and repair, allowing easy access to internal parts for regular inspections. In addition, these valves are constructed of high quality, heavy-duty materials, ensuring reliable, long-lasting operation in environments that handle hydrogen, a highly flammable gas.

I specify a little bit the technical details of this valve.

And as I know, that you like the technicalities, I leave you the valve’s data sheet.

Yeeeeesss, of course! Hydrogen valves can also be actuated, both with electric actuator and pneumatic actuator.

And why do you want to act as a valve?

Well, it is the most comfortable thing that exists. Let me explain:

Many times valves are positioned in places that are difficult to reach or where mobility is reduced. And that’s where an actuator is a life saver. With the actuator, you can open and close the valve remotely. Here are some clear benefits of buying an actuator with your valve:

Hey, and if after this, you still need more info or a hydrogen ball valve contact us.

Share this post

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to

You’ve probably heard about high-temperature or cryogenic valves, the ones that are incredibly resistant because they operate under extreme conditions. But what makes them so

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

Esta web utiliza Google Analytics para recopilar información anónima tal como el número de visitantes del sitio, o las páginas más populares.

Dejar esta cookie activa nos permite mejorar nuestra web.

Please enable Strictly Necessary Cookies first so that we can save your preferences!