Hydrogen Check Valves

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to

In the world of industry and energy, you have to be careful, especially when handling gases and liquids at high pressures.

High-quality, high-performance connections are used to facilitate the safety and efficiency of the equipment.

An example of such quality connections is the “cone & thread” of very high pressure. I’ll explain in a moment.

But first… Here’s a video where I explain everything in just 3 minutes (subtitles in English are available ;))

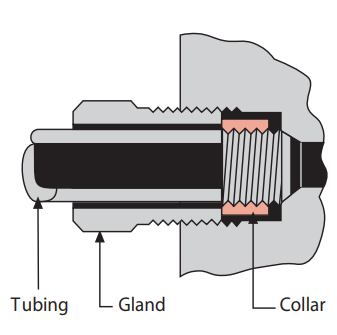

The first thing you should know is that it is a pipe fitting. But not just any pipe, no; cone & thread fittings are used to connect high-pressure pipes.

This connection consists of two parts: on the one hand, the male cone and on the other hand, the female cone with a thread.

The thread is screwed into the pipe and the cone is inserted, thus creating a tight seal. In fact, cone & thread connections are known for their high vibration resistance. And let’s not forget their ability to withstand high pressures.

And as I know that you like everything technical I leave you a technical data sheet of fittings and valves of very high pressure. Just click on the download button.

These powerful connections are logically used in industries that require handling of gases and liquids at high pressures, such as oil and gas.

They are designed to withstand extremely high pressures and are used in test equipment, measuring equipment and transfer systems, as we will see shortly.

Safety first, you know.

In addition to the “cone & thread” connections, there are four types of very high pressure valves on the market that provide added safety and high performance. These are:

Each one has its own characteristics and applications, so depending on what you need, you will have to choose one valve or another.

But be careful: as with the “cone & thread” connections, make sure that the valve you buy is of high quality, able to withstand high pressure and temperature conditions.

Very similar to the standard “cone & thread”.

The hermetic seal is created by joining the cone and the female; thus, the connection can withstand the pressure of the fluid without any problem, no matter how high it may be.

They are vibration-resistant connections, therefore ideal for use in industrial environments.

Keep an eye out, because the use of these special connections brings benefits such as these:

Given the benefits, shall we move on to applications?

There are several, of which we have highlighted these three:

Typical, no, very typical in the oil and gas industry.

These systems are used to test the integrity of equipment and pipelines before they go into operation.

You know what they say: better safe than sorry.

Yes, very high pressure “cone & thread” are also used in high pressure measurement systems to measure the flow and pressure of liquids and gases.

Measuring… and handling, of course.

Very high pressure “cone & thread” connections are also used in the oil and gas industry to transfer liquids and gases, as well as in other industries that may require high pressure treatment of these two elements.

I leave measurements and maximum pressures in a little table that is always good to see it with numbers.

| Size | max. working pressure | max. working pressure | OD | ID | Wall Thickness | Weight |

| Inch | Bar | PSI | mm | mm | mm | kg/m |

| 1/4″ | 1.380 | 20.000 | 6.35 | 2.77 | 1.79 | 0.21 |

| 1/4″ | 4.140 | 60.000 | 6.35 | 2.11 | 2.12 | 0.23 |

| 3/8″ | 1.380 | 20.000 | 9.53 | 5.16 | 2.18 | 0.4 |

| 3/8″ | 4.140 | 60.000 | 9.53 | 3.18 | 3.18 | 0.51 |

| 9/16″ | 1.380 | 20.000 | 14.29 | 7.92 | 3.18 | 0.89 |

| 9/16″ | 4.140 | 60.000 | 14.29 | 4.78 | 4.76 | 1.14 |

| 3/4″ | 1.380 | 20.000 | 19.05 | 11.13 | 3.96 | 1.5 |

| 1″ | 1.380 | 20.000 | 25.4 | 14.27 | 5.56 | 2.77 |

With that ability to withstand you’ll understand why they are essential connections in many equipment and installations in the energy world.

And with those associated benefits – the ability to withstand extremely high pressures, resist vibration and impact, and their ease of installation – they become an ideal choice for applications that require high performance and safety.

If that’s what you’re looking for in your equipment, cone & thread connections are a safe bet.

And nothing, I hope that’s clear. And if you still have any doubts, feel free to contact us. We’ll help you in any way we can.

Share this post

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to

You’ve probably heard about high-temperature or cryogenic valves, the ones that are incredibly resistant because they operate under extreme conditions. But what makes them so

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

Esta web utiliza Google Analytics para recopilar información anónima tal como el número de visitantes del sitio, o las páginas más populares.

Dejar esta cookie activa nos permite mejorar nuestra web.

Please enable Strictly Necessary Cookies first so that we can save your preferences!