NPT Swivel Nut: How to Achieve Rotating Connections with a Tapered Thread

Imagine you’re installing a pressure gauge on a pipeline and, as you screw it in, you realize that when it finally tightens… the dial is

So, you must be one of those who deal with seawater or saltwater every day.

Especially all the companies dedicated to desalination, desalination plants, water treatment, WWTP , drinking water treatment plants, and those that work with SWRO, BWRO systems, and a long list of other water treatments.

Let’s take a closer look at the different options we have at Redfluid to tackle the significant problem that these companies face… Corrosion!

As is well known, saltwater contains a high level of sodium chloride, and it is the chloride ions that can penetrate the protective oxide layers of metals and accelerate the corrosion process.

But that’s not all; we cannot solely blame saltwater for all these issues. The movement of water, the presence of other chemicals, and the constant humidity in reverse osmosis and water treatment also directly affect the equipment and facilitate corrosion. Not to mention the common and catastrophic mistake of combining two different metals without knowing if they are compatible, which can lead to galvanic corrosion.

But don’t worry, not everything in this blog is negative.

There are certain specific materials that are highly resistant to corrosion, such as Duplex, Superduplex, or nickel alloys like Cupronickel 90-10 or 70-30.

The downside of these special materials, besides the cost, is that they often come with very long delivery times, are rarely in stock, valves and actuators coming from different suppliers may not fit together properly, and there can be leaks in hydraulic hoses due to insufficient testing…

Finally, we reach the positive point. Get your notepad and pen ready. Here we go:

At Redfluid, we offer a wide range of products in Duplex and Superduplex. Let’s go step by step to see which special products we have for the desalination sector:

Here’s a video where I explain the products we offer for your industry.

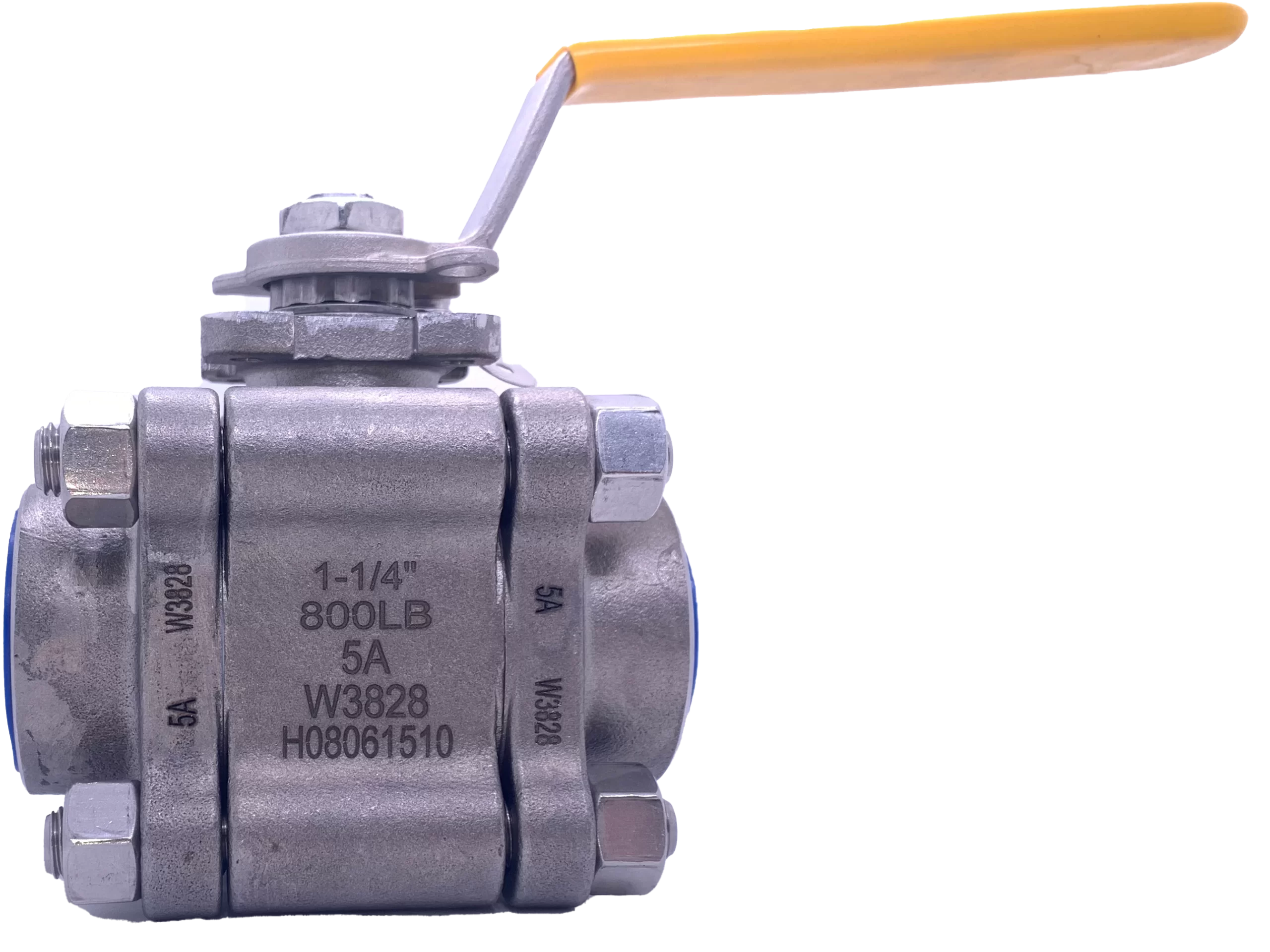

We usually have ball valves in super duplex from 1/4″ to 3″ in PN 140 in stock, which can be useful for the high-pressure lines of your installation. Additionally, they are ATEX certified and can be operated pneumatically or electrically.

Regarding connections, the most common ones are Socket Weld, NPT, or BSP. We can also manufacture them in Butt Weld (BW).

Yes, you heard that right!!!

We can handle the assembly of valve + actuator ourselves, which we know can cause a lot of headaches. Whether it’s a pneumatic or electric actuator, we have special actuators for desalination with epoxy coating or made of plastic materials. It’s much better to buy a complete, finished, and tested solution rather than picking from three or four different suppliers and then having everyone wash their hands if there’s a problem.

Our needle valves can range from 1/4″ to 2”, also in high pressure. Like our ball valves, they have a PREN > 40, recommended for high salinity content. We have the most common sizes in stock, and if we don’t have them, we can manufacture them in no time.

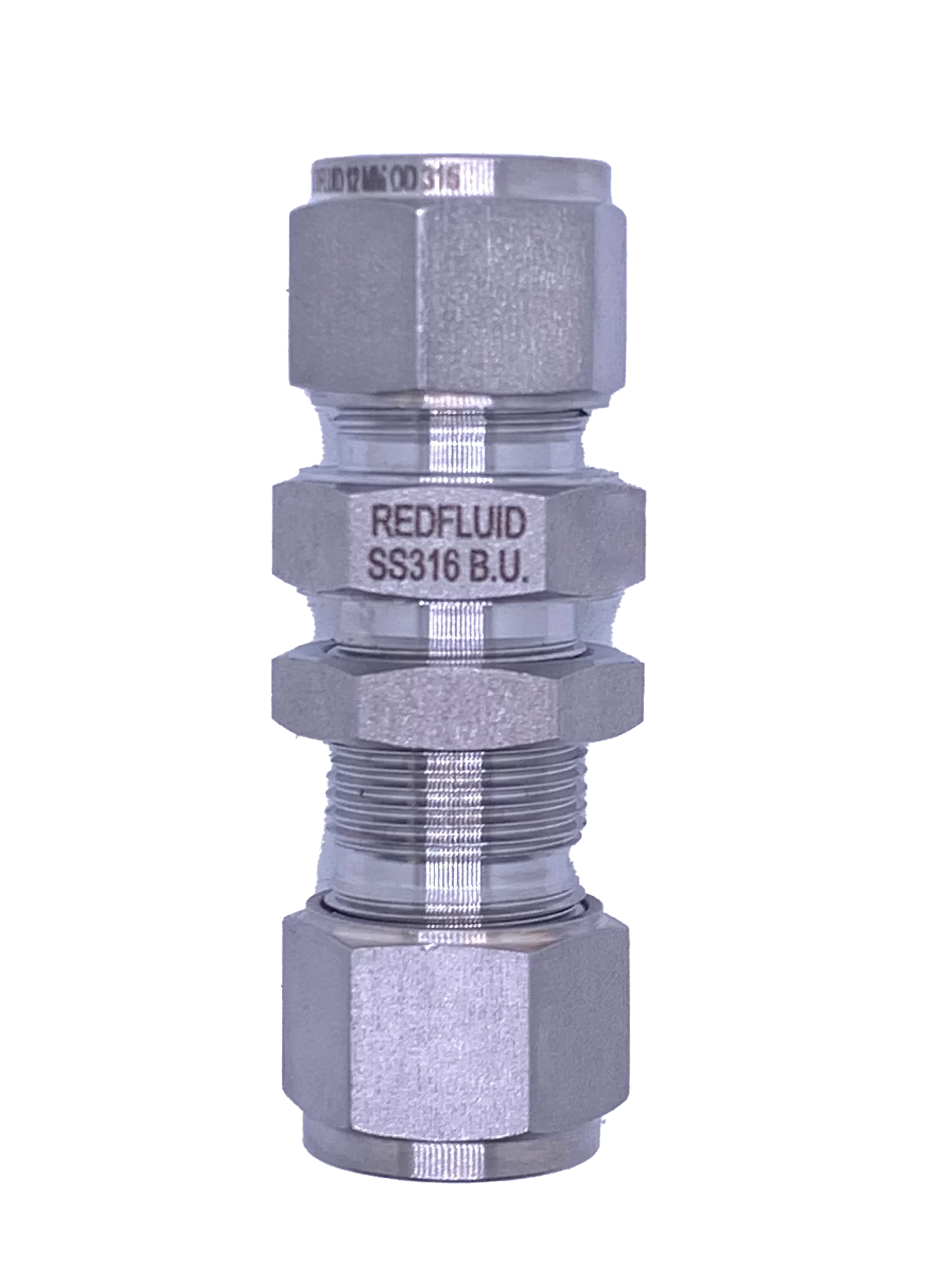

Yes, compression fittings of the double ferrule type and the tubing can also be made in Superduplex. They are manufactured in the sizes and pressures you need. These fittings are suitable for high-pressure lines, and we offer tubing in various diameters, including jumbo sizes in Superduplex.

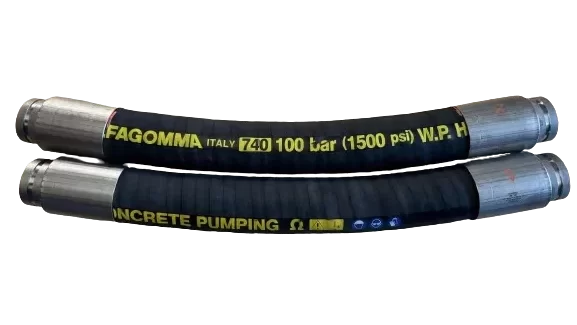

We offer the classic and conventional threaded connections, either BSP or NPT. A safe and viable option. Terminals in Superduplex or Cupronickel. Bell in 316 or alloys. We can manufacture them with a variety of hose types.

But, not everything is limited to the classic threaded connections. Watch out! Because we also have Victaulic Grooved Superduplex Whip Hoses, which are ideal for desalination or water treatment companies, or for connecting to pumps. We can offer sizes ranging from 1/4” to 3”, with a working pressure of up to 100 bar! It is very common to use 3” flexible hose with Victaulic grooved connections PN100 or PN80 in Superduplex. And to top it all off, they are 100% tested in our laboratory with certain equipment, which we will see later.

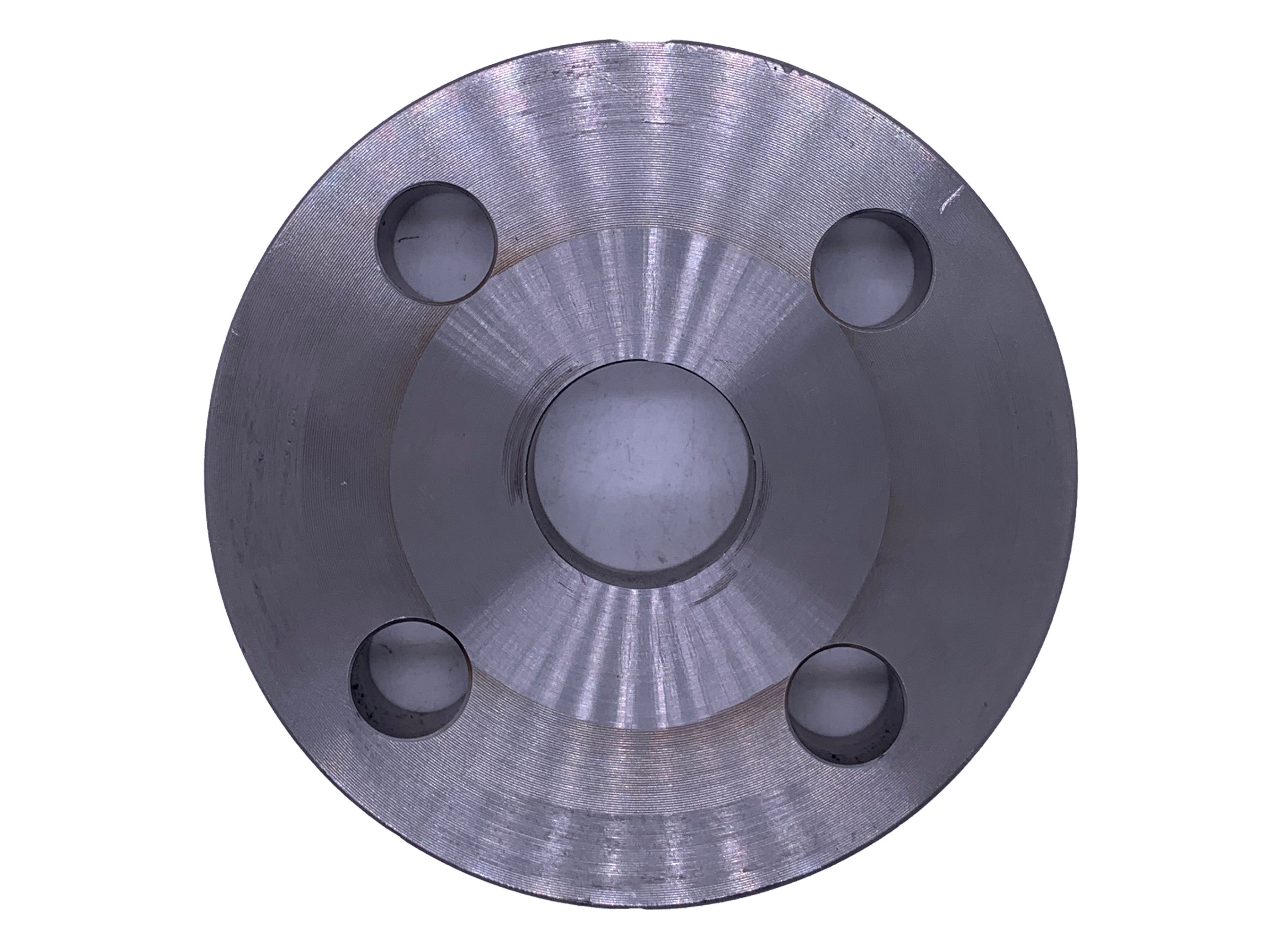

In any desired material, we offer all types of flanges, whether in ASME B16.5 or EN 1092 standards. We have all types of flanges, such as flat face flanges, blind flanges, etc.

One of the major highlights of flanges is their ease of maintenance, as they allow for very simple assembly/disassembly, and their versatility to adapt to different needs and specifications required.

All types of accessories, such as tees, elbows, crosses, and anything else you can imagine. The correct selection of materials for threaded and weld fittings is essential to ensure proper operation and maintenance and to avoid all types of corrosion. For welding, we offer connections in type 3000 or 6000 SW or SCH40 or SCH80 in all diameters.

On the other hand, we have a device called an X-ray fluorescence spectrometer, which is used to verify the material, determine its specific composition, and therefore, we can provide a 3.1 certificate accordingly.

Speaking of equipment, we also have a test bench to check the pressure that different equipment can withstand. Therefore, you can forget about the problem that a leak in the whip hose or flexible hose might cause.

Don’t let corrosion hinder the performance of your valves, tubing, piping, or fittings!

At Redfluid, we are here to offer you solutions to all types of problems related to corrosion caused by saltwater.

If you have any questions or need specific advice, don’t hesitate to contact us. We are here to help!

By the way, I visited the Llobregat desalination plant the other day and was thrilled to see our valves installed there. Here’s a video of the visit:

Share this post

Imagine you’re installing a pressure gauge on a pipeline and, as you screw it in, you realize that when it finally tightens… the dial is

Sounds familiar? The technician looks for a fitting, maintenance can’t find it, purchasing places an urgent order “for yesterday”… In the end, production gets delayed,