Flushing Ring: the key to cleaning and calibration without disassembly

Imagine you’re running an industrial plant and you’ve got a diaphragm seal protecting a pressure transmitter. Over time, the process fluid starts leaving deposits and

Throughout the 19th century, when a manufacturer needed a connection for hydraulic or pneumatic circuits, he went to the workshop and solved it in the most convenient way for him. As a result, each house used a different type of thread or connection, creating a major incompatibility problem.

This was the case until Sir Joseph Whitworth, an English mechanical engineer, appeared on the scene. The Whitworth thread that we still use today was the proposal that this manufactured to solve the incompatibility problem that existed. This type of thread was chosen as the standard for connecting pipes because when one of its threads was cut, it became a self-sealing thread, making it the BSP thread (or British Standard Pipe Thread).

Sure enough, on the other side of the pond, a different standard was established, this time by William Sellers, for the use of nuts, sleeves, and bolts. His invention, the NPT Thread (American National Pipe Taper Thread), became the American standard.

And so we arrive to our days, where we manage different standards at international level with similar applications. This mixture of acronyms makes it difficult to really understand the characteristics of each type of thread and, therefore, how they differ from each other, whether they are compatible or incompatible, etc.

That is why we have prepared this article in which we clarify once and for all the differences and compatibilities between BSPP (or Gas), BSPT, and NPT threads.

Let’s get down to business.

But first of all, I’ll leave you with a short video that sums it up very quickly.

Before you continue… here’s a little gift for you, an infographic where I explain EVERYTHING in a VERY SIMPLE way.

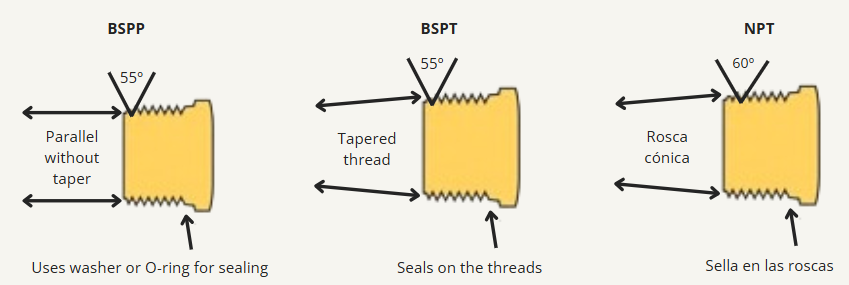

We start talking about BSP threads, which, as we said in the introduction, are Whitworth system threads and therefore based on a 55 degree angle thread. It is the standard that has been adopted worldwide (except in North America) for the connection and sealing of pipes and fittings by coupling an external thread (male) with an internal thread (female).

Within the BSP threads, we can differentiate between two different threads, and this is where the party starts:

Therefore, in the case of BSPP threads, the idea to be clear is that both males and females are always parallel threads, i.e., both are assembled with the same cylindrical thread. In these assemblies, adding some kind of sealing material to the joint is recommended.

Here are some of the main rules to consider for this type of thread.

For Whitworth threads, the standard is grouped differently depending on their threads’ sealing type. For BSPP or Gas threads, where sealing has to be produced by other means, the cases are covered by DIN ISO 228/1 and equivalent standards:

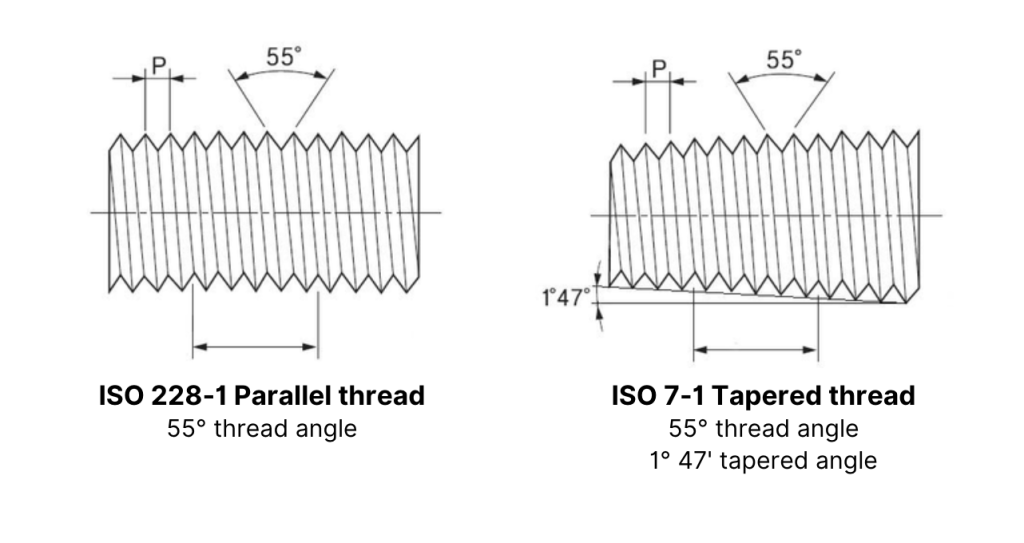

As we have just explained when talking about the parallel thread, the BSPT is a tapered thread. That is, the diameter of the thread varies along the length of the thread. The difference in shape between a parallel thread and a tapered thread can be seen in the following figure:

Here are the main rules to take into account.

For BSPT threads, where the pressure of its threads produces the sealing, the cases are contemplated in the ISO 7/1 – DIN 2999 and BS 21 Standards.

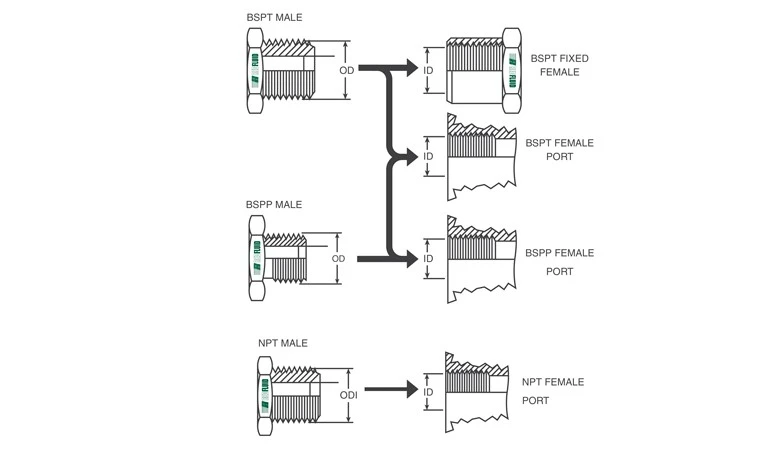

Having clarified what type of thread each one is and what their differences are, let’s see how these threads can be assembled, a point on which there is often confusion. The golden rule is straightforward: a tapered male can fit a tapered or parallel female.

That is, a BSPT (tapered) male thread can fit both a BSPT (tapered) and a BSPP (parallel) female since the taper of the male will fit equally into a cylindrical thread. In the case of using a tapered tap on a parallel female, sealing material is recommended to ensure the tightness of the joint.

However, a BSPP (parallel) male thread will only fit into a cylindrical (BSPP) female thread, as it will be impossible to fit into a tapered recess.

All this is reflected in the following figure:

As mentioned in the introduction, although the BSP thread had become a recognized standard a couple of decades earlier, the American William Sellers succeeded in getting this type of thread adopted as the one used in most public works and railroads. As a result, today, it is the most widely used thread type in the United States and Canada.

NPT threads differ from BSP threads in the tooth angle, which is 60 degrees instead of 55, and the edges are more pronounced. Another difference is in the pitch: NPT threads have 11.5 threads per inch while BSP threads have 11 threads per inch.

NPT threads are tapered in both female and male, although there are variants that we will explain below. NPT threads are only compatible with other NPT threads.

A detail that must be taken into account is that NPT threads do not ensure tightness by themselves, so it is recommended that some sealing material be applied to the tap, such as Teflon tape or thread sealant.

The following figure shows the difference in shape between BSPP, BSPT, and NPT threads:

In terms of designations, different names can be found to refer to male or female NPT threads:

There are also different variants of the NPT thread, which complicates everything a little more. Among all of them, it is important to highlight the following:

YES! NPT and NPFT threads are compatible with each other. Normally there is an interference fit between the root and the crest on the larger or smaller diameter of the thread, depending on where the NPTF thread is located. In addition, if we mix NPT and NPTF, it will be necessary to use a sealing material to ensure the tightness of the joint.

As for NPTF and NPS (or NPFS) threads, as we said above, they can be combined using an NPTF male (which is a conical thread) on an NPS female, achieving a tight connection. In any case, the combination of a parallel thread and a tapered thread is not the ideal union, although they are frequently used.

Now that we have discussed these two standards, let’s see what compatibilities and incompatibilities exist between them.

BSP and NPT threads are not interchangeable, as they have different pitch and flank angles.

Attempting to join an NPT male to a BSPP female will cause the joint to lock within a few turns. If an attempt is made to join an NPT male to a BSPT female, the male will fit more, but the joint will also become stuck.

In these cases, because of the difference in thread shape, a spiral leak will occur.

As in the previous cases, we leave here rules applicable to the NPT

We hope this article has helped you solve your doubts about these types of joints and their possible combinations and incompatibilities. In any case, if you have any questions or need advice for your project, do not hesitate to contact us.

At Redfluid, we are happy to offer all our customers the advice they need to find the best fitting solution for their projects. You don’t need to be an expert in valves and fittings, we will take care of that part for your installation to go ahead.

Also, if you do not find any type of union that meets the requirements you need, Red Fluid can manufacture it for you in a completely customized way. If you need a custom part, here is more information on making it for you.

Share this post

Imagine you’re running an industrial plant and you’ve got a diaphragm seal protecting a pressure transmitter. Over time, the process fluid starts leaving deposits and

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to

7 Responses

I am struggling to understand the 1 to 16 taper rule in BSPT (ISO 7-1). How did you work out that the angle of the taper was 1° 47′? Just so I can wrap my head around it, because if I were to add one UOM in height every 16 UOM in length the angle adds up to be 3° 35′. I would love to hear back from you about this so I can finally put my confusion to rest

Hi Caleb, don’t worry I’m here to put your confusion to rest.

Let me explain.

When you calculate the angle you cannot think that it’s a triangle, thus you can’t use the calculations that you’d use for a triangle. You have to think at it, as it was another geometric figure called tapered figured. For it you have the following calculations:

Tapered= 1/16

Tapered= 2*tan(α)

Now, if you change the formula, you’d have the following:

α = arctan (0,0625/2)

α= 1°47

This formula is according to EN ISO3040. But, attention! You have to look what α in each case is. In this case we have used alpha, but depending on what you describe as alpha in your drawing you can also use α/2.

I hope it was clear enough and that now you can put your confusion to rest.

If you have any other concerns, we’ll try to help you with them ASAP.

Great guide, very informative and to the point.