NPT Swivel Nut: How to Achieve Rotating Connections with a Tapered Thread

Imagine you’re installing a pressure gauge on a pipeline and, as you screw it in, you realize that when it finally tightens… the dial is

Surely, you’ve heard of the ASME B16.11 standard for pipe connection fittings—NPT, BSP, Socket Weld… But what exactly is it, and why is it so important? Let me explain it to you as if we were having a coffee together.

So, get up, head to the kitchen, and grab a cup of coffee because we’re diving in.

ASME B16.11 is like the recipe for connection and union fittings in piping systems. It defines how elbows, tees, couplings, and reducers should be designed to ensure smooth operation in high-pressure systems across various temperature ranges.

In essence, it provides guidelines on the geometry of the components, the pressure they can withstand, the materials they should be made from, and more.

Here’s a video where I explain everything in just 4 minutes!

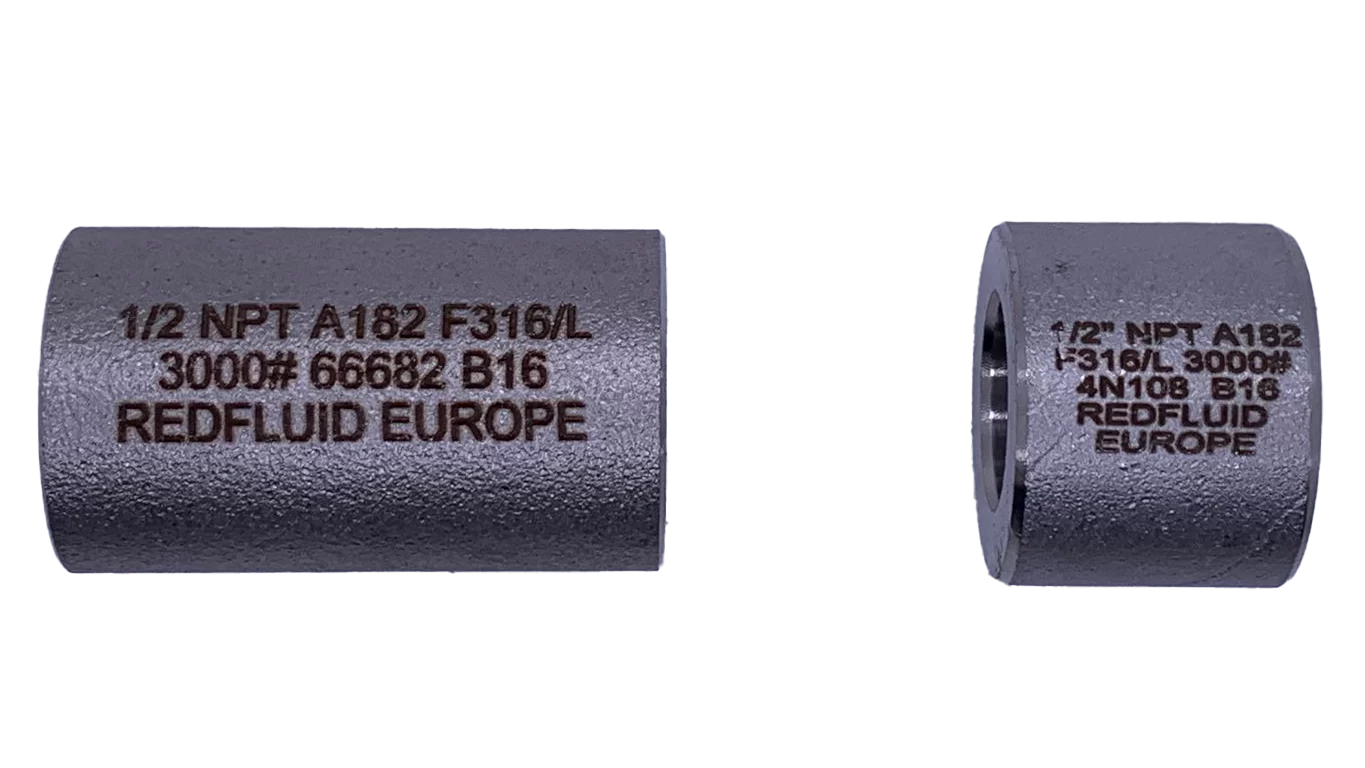

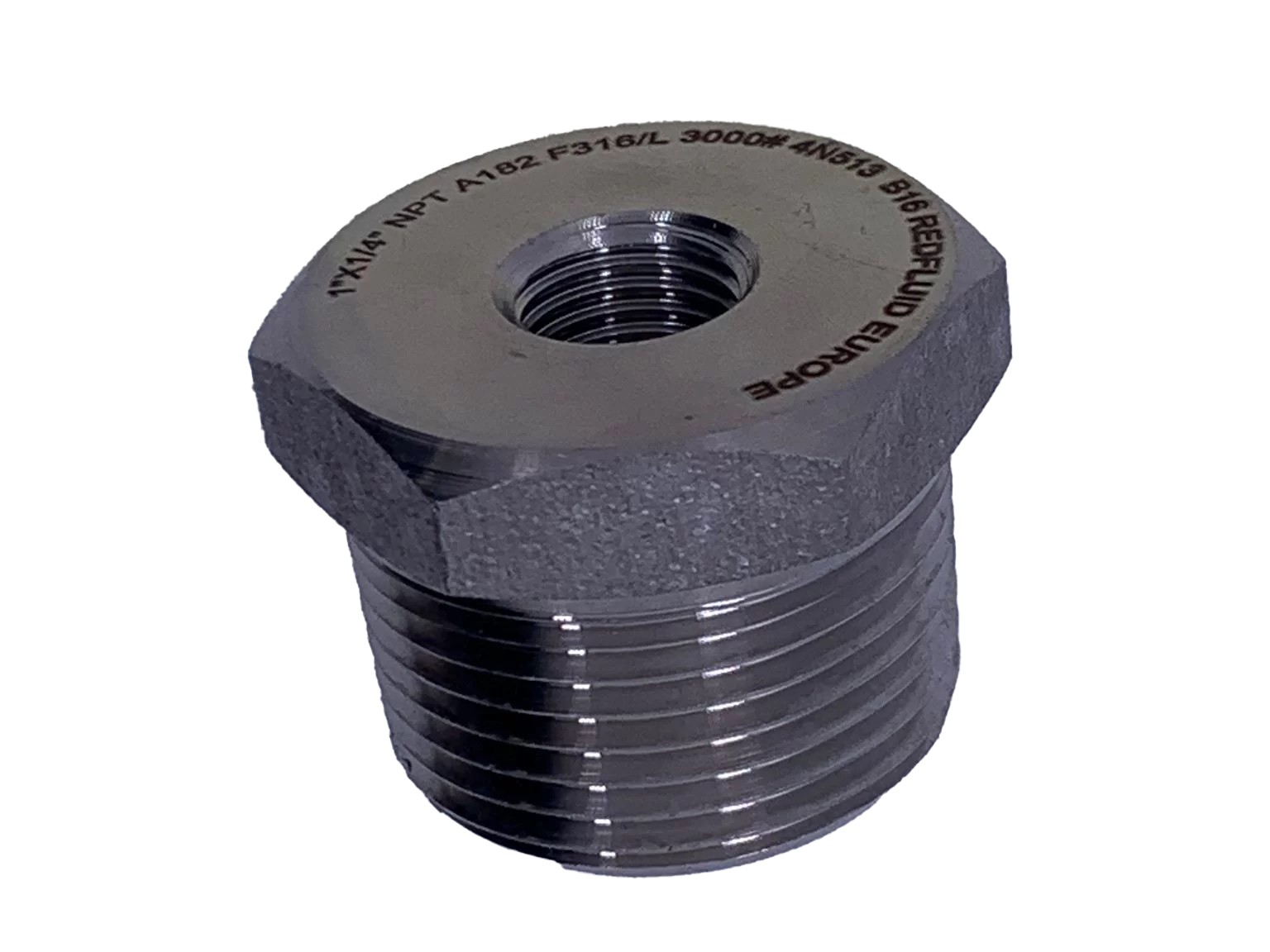

Up next, I’ll show you some of the endless—or nearly endless—possibilities we offer at Redfluid.

Here’s the link to the ASME B16.11 fittings in our catalog, in case you’d like to take a look:

It’s worth mentioning that we offer a wide range of manufacturing materials—from readily available options like A105 Carbon Steel and 316 Stainless Steel to harder-to-find nickel alloys such as Inconel, Duplex, or Super Duplex.

Male-female adapters are fittings used to connect pipes with different types of connections. One end of the adapter features a male thread, which connects to a female fitting, while the other end has a female thread, designed to connect to a male fitting.

Their most common application is in piping systems requiring different thread types or sizes.

A swage nipple is a conical fitting used to connect two pipes of different diameters. There are various types:

If you want a quick refresher on the different types of nipples available, click HERE.

But you might be wondering…

It’s quite simple! Let me quickly explain the types of connections we offer:

If you’d like to learn more about the types of threads, their compatibility, and other interesting details, click HERE.

Well, reading what I just wrote, it seems like I didn’t go into much detail about this connection type. Ahem, excuse me, a link to an interesting blog about Socket Weld just slipped in here.

You might be wondering: “What could be more interesting than everything you’ve explained so far?”—at least, that’s what I’d be asking myself… The answer is…

THE GREAT DILEMMA OF THE 3000 SERIES AND SCHEDULES

In case this doesn’t ring a bell, let me introduce you to the issue that drives all of us working with fittings, schedules, and pressures absolutely crazy.

ASME B16.11 does NOT specify the maximum pressure a fitting can withstand.

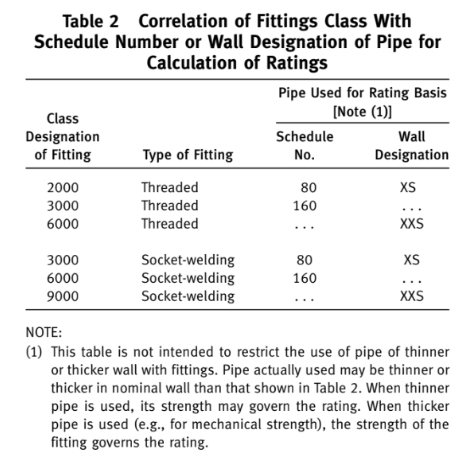

Although we traditionally associate the 3000 series with 3000 psi (around 248 bar) and the 6000 series with 6000 psi (around 414 bar), what ASME B16.11 actually states is the following:

How is this table interpreted?

It tells us that an S3000 fitting can be used with pipes up to SCH 160. (Remember, SCH refers to the pipe thickness according to ASME B36.10M. If you need a refresher on SCH, you can check out this video:)

So, this means that a THREADED S3000 fitting can withstand the pressure of a pipe with SCH 40, SCH 80, and even SCH 160. On the other hand, if the fitting is SW type S3000, it can be used with pipes up to SCH 80, but not SCH 160.

And you might ask, Hey Kike, how do I know the pressure a 1/2″ SCH 160 pipe in Stainless Steel 316 can handle?

It’s super easy—just head over to our pressure calculator, and you’ll be able to check the pressure the pipe can handle for that specific diameter and thickness.

Click here to access the calculator.

Be aware that thicknesses, pressures, etc., vary depending on:

If you need us to calculate it for you to recommend the most suitable fitting without wasting a single euro, feel free to contact us. And if you don’t want to overthink it, you can stick to the classic rule: 3000 for 3000 psi (240 bar) and 6000 for 6000 psi (400 bar)—you’ll almost certainly get it right.

I hope this has helped you understand the world of the ASME B16.11 standard a little better. If you have any questions or just want to share your thoughts, we’d be more than happy to chat with you!

And as you know, whenever the opportunity arises, we’ll be here to keep sharing knowledge. For now, the coffee is finished, but next time, we’ll be back with more interesting topics.

Share this post

Imagine you’re installing a pressure gauge on a pipeline and, as you screw it in, you realize that when it finally tightens… the dial is

Sounds familiar? The technician looks for a fitting, maintenance can’t find it, purchasing places an urgent order “for yesterday”… In the end, production gets delayed,