Hydrogen Check Valves

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to

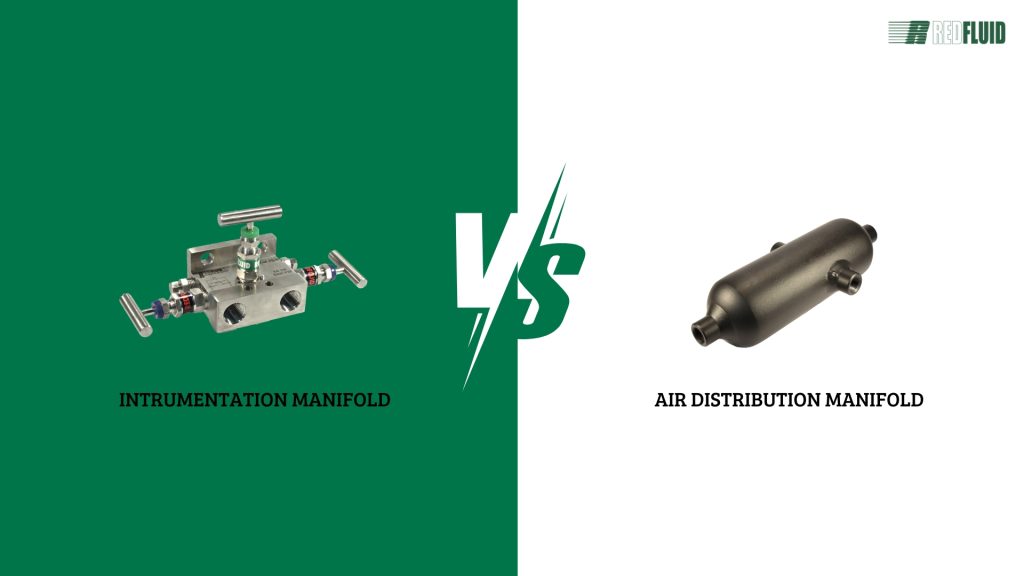

Before ordering a Manifold, we must be clear that what we are really ordering is a Manifold.

It sounds very obvious, but more than one person asks me for Manifolds and wants something else.

They are normally installed together with a pressure transmitter in Hook Up’s or modular instrumentation system.

Be careful, because there are two products that have the same name, but are different:

Instrumentation Manifold: This is the one we are talking about in this article and refers to manifolds that are installed next to a pressure transmitter.

Air distribution manifold, also called “Air Header”, Barrel, Manifold, Distributor or Condensate Pot. Many names, but it’s all the same.

Now that it is clear to you what we are talking about, you can read our article that talks about the types of Manifold we have at Redfluid. In this article we also explain the difference between a one-valve, two-valve, three-valve and five-valve manifold. As well as two-way and three-way manifolds. Well, it’s worth it:

So, let’s get down to business.

If you go to our Manifold catalog you can see the different types of Manifolds. I leave it below: https://redfluid.es/wp-content/uploads/2021/10/Seccio-E-Manifolds.pdf

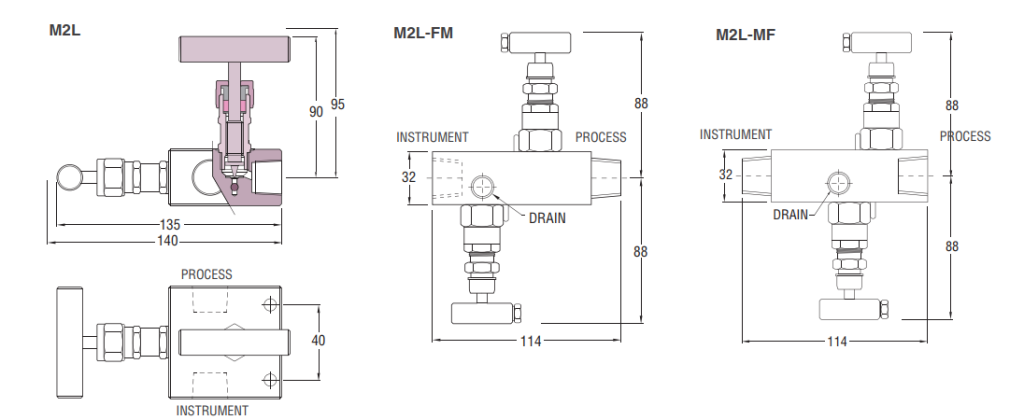

First: the connections must be separated according to the side (upstream or downstream) of the manifold. They are called Process and Instrument.

Logically, the process is the side where the pipes that are working and the instrument where the instrument that is going to measure the pressure or flow rate is connected. Kind of obvious.

A third option is venting (Vent, Bleeder or Drain). As the name indicates, it is normally used to drain the section between the manifold and the instrument.

That is why in all manifold diagrams we will find indicated the two sides: Process, Instrument and a third Purge (Drain or Vent both are synonyms).

Having this more than clear, we can now define the connection on each side. The most common connections are threaded or flanged.

If they are threaded they can be Male or Female and normally in BSP or NPT. The most common sizes are 1/4“ and 1/2”.

Therefore we must indicate, for example:

Instrument Female 1/2“ NPT, Process 1/2” Male NPT, Purge 1/4” Female NPT.

Another very common but confusing option is:

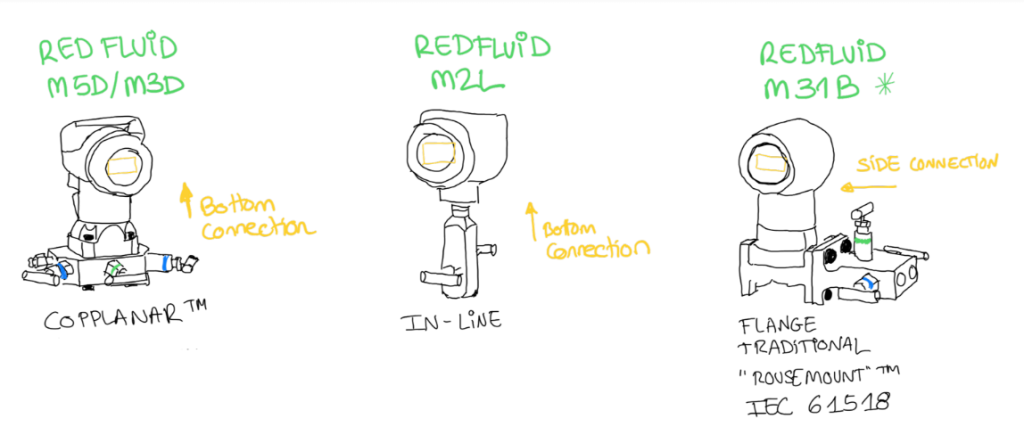

Coplanar ™ connection: When the manifold is installed below the pressure transmitter.

Flanged Connection: When the manifold is installed on the side or one side of the pressure transmitter. These are also often referred to by Emerson’s Rosemount™ brand name.

Important! Redfluid’s M5D and M3D models are also compatible with the traditional flange mounting system, you would not only be limited to the M31B model.

Later we will see the norm or standard that follows the geometry of this flange.

In-line connection: On the other hand, when the Manifold is connected directly to a normal pressure gauge, the most commonly used are the double-valve ones with Female to Instrument thread (since the gauge is normally Male) and Male to Instrument thread. Remember that we always recommend to place a siphon before a pressure gauge. If you think that you do not need a double valve, you could also use a Redfluid valve from the Manometer Series that comes standard with Male x Female and with Purge.

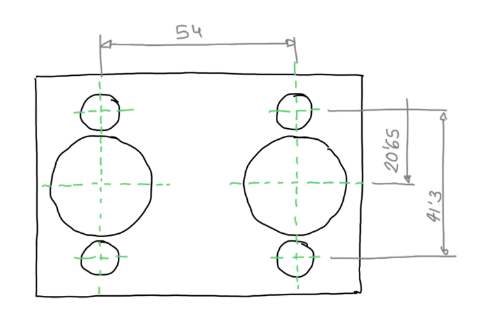

The distance between holes of the Manifold connection flange to the pressure transmitter follows the IEC 61518 standard (UNE-EN 61518:2001). The EN 61518 standard follows the same dimensions as the old and already repealed DIN 19213 standard. Therefore, if in any customer or engineering specification you come across DIN 19213, don’t worry. The manifold will match well with the current IEC 61518, which is the standard also followed by Redfluid manifolds.

Although DIN 19213 is still mentioned in some technical documents, it is no longer relevant because it has been replaced by IEC 61518. This includes all the necessary updates in design and materials to ensure a safe and durable connection. So, you can feel free to use IEC 61518 and, as far as possible, try not to continue specifying or ordering the old DIN. Some joint tolerances have been greatly improved in the new 61518.

The standard implies that the distance between holes of the interface between manifold and pressure transmitter should be as follows:

It also indicates that the hardware to be used for this connection should be 7/16″-20 UNF per ANSI B 18.2.1.

Hey, and if you still have doubts about which Manifold to choose, I’ll make it easy for you.

If you still have doubts about which manifold to choose, we make it even easier for you. Contact Redfluid and we will help you choose the best manifold for your installation. Remember that Redlfuid manifolds are perfectly compatible for installation on pressure transmitters of all brands such as Emerson ® Rosemount ®, Yokogawa ®, Schneider ®, Vega ®…

Easy peasy.

Share this post

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to

You’ve probably heard about high-temperature or cryogenic valves, the ones that are incredibly resistant because they operate under extreme conditions. But what makes them so

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

Esta web utiliza Google Analytics para recopilar información anónima tal como el número de visitantes del sitio, o las páginas más populares.

Dejar esta cookie activa nos permite mejorar nuestra web.

Please enable Strictly Necessary Cookies first so that we can save your preferences!