Hydrogen Check Valves

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to

This article will fit you like a glove. I will explain in 5 minutes what types of hydraulic fittings exist.

Hey, a word of advice!

As you read the article, click on the different types of fittings. It will open a new tab to see each type in more detail. I know you love to know more.

So, let’s go!

A quick definition of fitting:

Fittings are mechanical elements that allow two or more pipe or hose elements to be connected safely and efficiently. There are several types of fittings used in different applications and environments, each with its own characteristics and benefits.

Hydraulic fittings are a special type of fitting used in hydraulic systems to connect pipes and hoses that carry fluids normally under high pressure. These hydraulic systems are in a wide variety of applications, from heavy machinery, process industry, and construction vehicles to industrial production equipment and lifting and handling systems.

We design Hydraulic fittings to withstand high pressures and temperatures. They provide a tight, secure connection in demanding working environments.

They can be made from a variety of materials, such as stainless steel, brass, aluminum, or plastic. In addition, they can be available in a variety of shapes and sizes to suit the needs of each application (straight, elbow, tee, cross…).

Let’s get down to what is interesting, as I guess it is already clear to you what a fitting is.

They are divided into two main categories: high-pressure fittings and low-pressure fittings. High-pressure fittings are used in systems that convey fluids at high pressure, such as hydraulic systems of heavy machinery or drilling equipment.

Low-pressure fittings are used in systems that convey fluids at low pressure, such as lubrication systems. They are connected to pipes and hoses by different methods, such as threading, compression, or mechanical bonding.

They can also have different shapes, such as straight fittings, elbows, tees, or cross fittings. These allow pipes and hoses to be joined at different angles and configurations. It is important to select the right type of hydraulic fitting for each application to ensure a secure and durable connection.

In addition, hydraulic fittings must be installed and maintained correctly to prevent leaks and damage to the system. In summary, hydraulic fittings are a key component in hydraulic systems. They are essential to ensure the safe and reliable operation of the equipment and machinery that use them.

Let’s look at the different types in a little more detail.

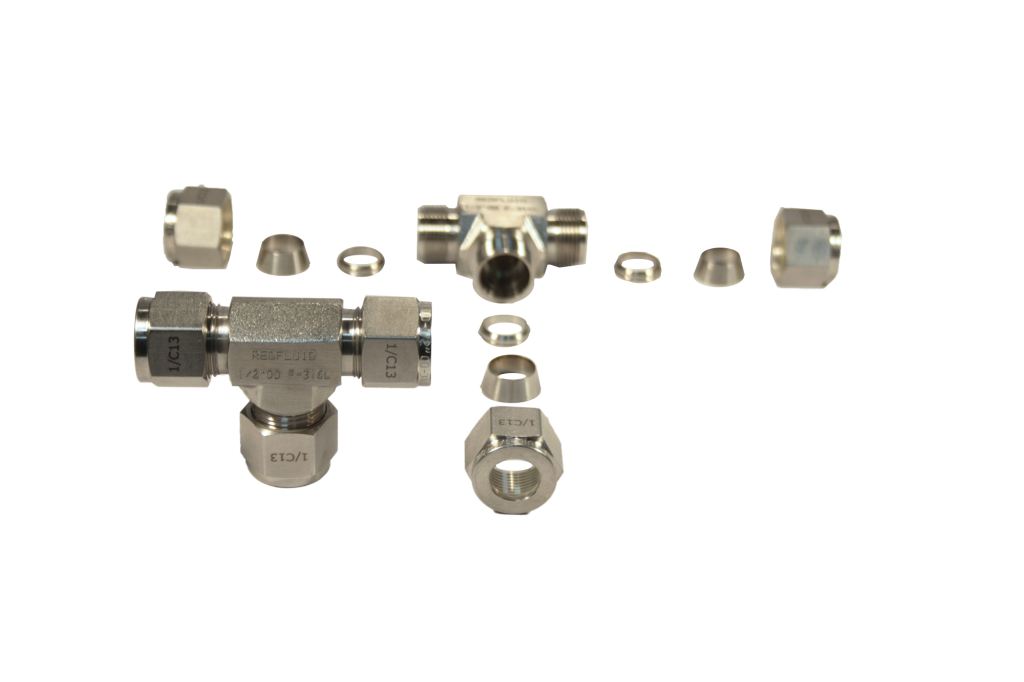

A double-ring compression fitting, also known as a compression union fitting, double olive fitting or double ferrule, or “Swagelok” fitting, is a type of fitting used in piping and hose systems to create a secure, leak-tight connection. This type of fitting is commonly used in medium or high-pressure fluid handling applications.

Simply connect them to the pipe and tighten them with a wrench or open-end wrench to achieve a watertight connection.

One of the advantages of double-ring fittings is that they are relatively easy to install and do not require soldering glue, or special tools.

Another advantage of double-ring fittings is that they are very versatile and can be used with different sizes of pipes and hoses, such as copper, stainless steel, and plastic tubing. It is important to make sure that the double ring fitting is compatible with the type of tubing used and that it is seamless.

And, stay tuned, because I have all the sizes and fittings you need. Elbows, reducers, crosses, tees, valves, sleeves, and many more. In addition, I manufacture them in 316/L stainless steel. They can also be manufactured in 904, Alloy 20, Duplex, Superduplex, Incoloy, Hastelloy, Inconel, Monel, or other materials upon request.

And if you want the technical data sheet of the double ring fitting, don’t be shy and click on download:

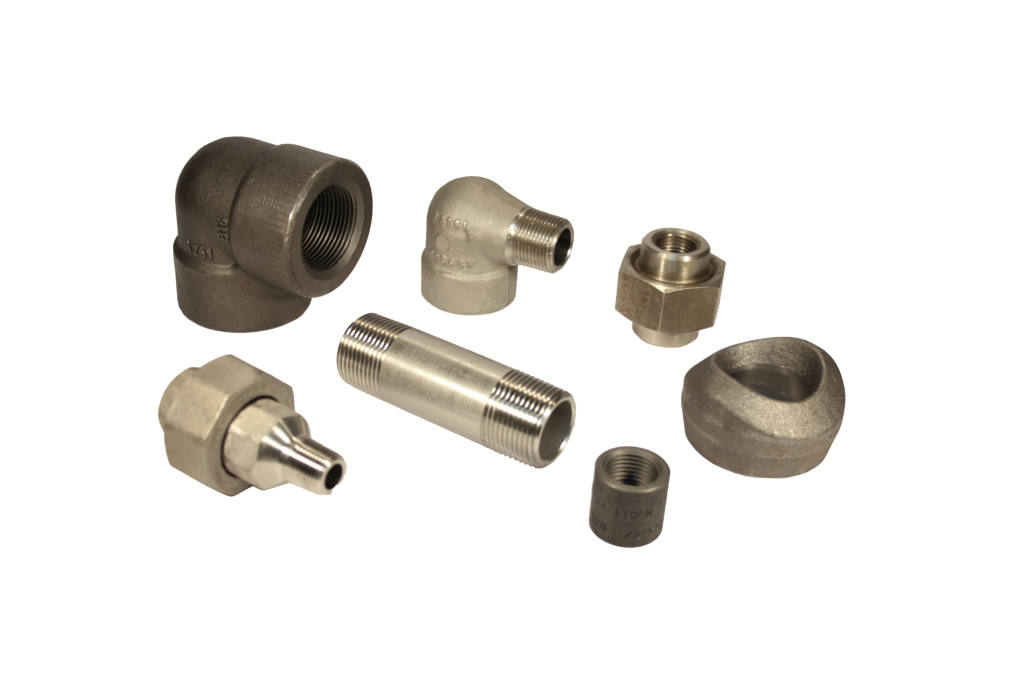

ASME B16.11 3000, 6000 and 9000 PSI fittings are a type of high-pressure fitting used in industrial applications where a secure, high-pressure resistant connection is required. These fittings are designed and manufactured to American Society of Mechanical Engineers (ASME) B16.11 specifications. They are available in different sizes and shapes to suit the needs of each application.

The number used to describe these fittings (3000, 6000, and 9000 PSI) indicates the ASME pressure rating they can withstand. ASME B16.11 3000 PSI fittings are suitable for high-pressure applications requiring a maximum strength of up to 3000 pounds per square inch. ASME B16.11 6000 PSI fittings are suitable for even more demanding applications requiring a maximum strength of up to 6000 pounds per square inch. Finally, ASME B16.11 9000 PSI fittings are the strongest. They are used in applications requiring a maximum strength of up to 9000 pounds per square inch.

This standard covers NPT and Socket Weld connections, although we also have them in BSPP.

And if you want the ASME Fittings datasheet download it in a second here:

As you can see, I am giving you little gifts with the technical data sheets. In the end, it is all very well to know what each one is, but it is necessary to know more in detail.

Let’s go to the single-ring fitting.

Redfluid’s single-ring fittings are designed for joining pipes and tubing in hydraulic systems and comply with the Deutsches Institut fϋr Normung DIN 2353 / ISO 8434-1 standard. These fittings are available in different sizes, from 4 to 42 mm OD, to suit different tubing or pipe diameters. Depending on the series and pipe diameter, these fittings can withstand up to 800 bar.

The range of single-ring fittings includes a wide variety of shapes, such as straight, cross, tees, elbows, mixed male or female x-ring thread, wall bushings, and weld fittings, among others. These fittings are available in two standard materials: 316 stainless steel and carbon steel.

In summary, Redfluid’s single-ring fittings are a reliable solution for connecting pipes and tubing in hydraulic systems and are available in different sizes and shapes to suit the needs of each application. In addition, their ability to withstand high pressures makes them ideal for applications that require additional strength.

If you are interested in seeing the difference between a single ring fitting and a double ring fitting in much more detail, you can click HERE.

And as in any case, here is the technical data sheet of the single ring:

There are two types of automatic and quick fittings available: Push-in fittings and push-on fittings.

Both types of fittings are available in brass or stainless steel and can be found in a wide variety of shapes and forms, and in different threads, including BSP, BSPT, NPT, and metric. They are also available in different dimensions, from 4 mm to 16 mm outside diameter (OD).

If you are a fan of this type of fittings, I recommend downloading the quick and automatic fittings datasheet:

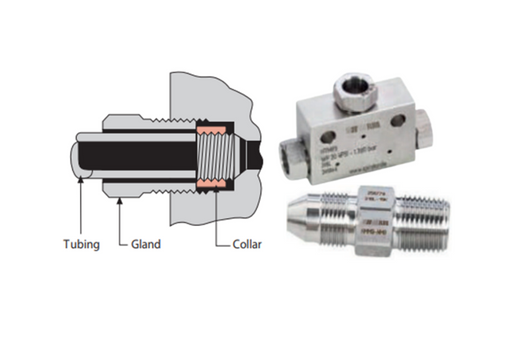

There is a wide range of products that are suitable for working pressures above 400 bar, up to 4140 bar. For high pressures, special connections known as “cone & thread” MP (Medium Pressure) or “cone & thread” HP (High Pressure) are used. MP products normally work up to 1380 bar, while HP products can work up to 4140 bar.

Needle valves, ball valves, and check valves are included, as well as fittings in different shapes, such as elbows, tees, sleeves, and plugs. In addition, the fittings are available in Male x Male, Male x Female, or Female x Female versions. It is one of the typical fittings for hydrogenerators or high-pressure hydrogen pipelines. The connection is watertight and high pressure. These fittings can only be connected to pipes with specially coned ends compatible with the rest of the fittings. We provide a complete solution for the coning of any installation and we supply already coned according to your lengths.

They are usually manufactured in 316 stainless steel. If you do not find the adapter you are looking for, we can manufacture it for you.

You can also download the technical data sheet of the high-pressure fittings and valves. And this is the last of this article:

This part is very useful, either way aim well.

In the industrial world, the safety and reliability of equipment and systems are of vital importance to ensure process quality and efficiency. In this regard, fittings and other pipe fittings must comply with a number of norms and standards to ensure their quality and performance.

Well, I don’t want to go on any longer, otherwise I’ll be labeled as tedious.

I hope this article has been useful for you to better understand the different types of fittings and their characteristics.

If you have any questions or need more information about our products or services, do not hesitate to contact us. We are at your disposal to help you in everything you need and offer you the best solution for your specific application.

Share this post

Imagine installing just any check valve in a hydrogen circuit. At first, everything seems to work fine — but over time, internal materials begin to

You’ve probably heard about high-temperature or cryogenic valves, the ones that are incredibly resistant because they operate under extreme conditions. But what makes them so

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

Esta web utiliza Google Analytics para recopilar información anónima tal como el número de visitantes del sitio, o las páginas más populares.

Dejar esta cookie activa nos permite mejorar nuestra web.

Please enable Strictly Necessary Cookies first so that we can save your preferences!